Wind collecting vertical type wind power generating system

A wind power generation system, wind vertical technology, applied in the direction of wind generator components, wind engines, wind motor combinations, etc., can solve the problem of large start-up dead angle and reversing dead angle, small wind-receiving area of wind blades, and large wind resistance of front wing surface and other problems, to achieve the effect of good dynamic balance characteristics, elimination of dead angle of fan blades, and large wind receiving area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0070] The technical solutions of the present invention will be further explained below in conjunction with the drawings and embodiments, but the following content is not intended to limit the protection scope of the present invention.

[0071] The overall structure

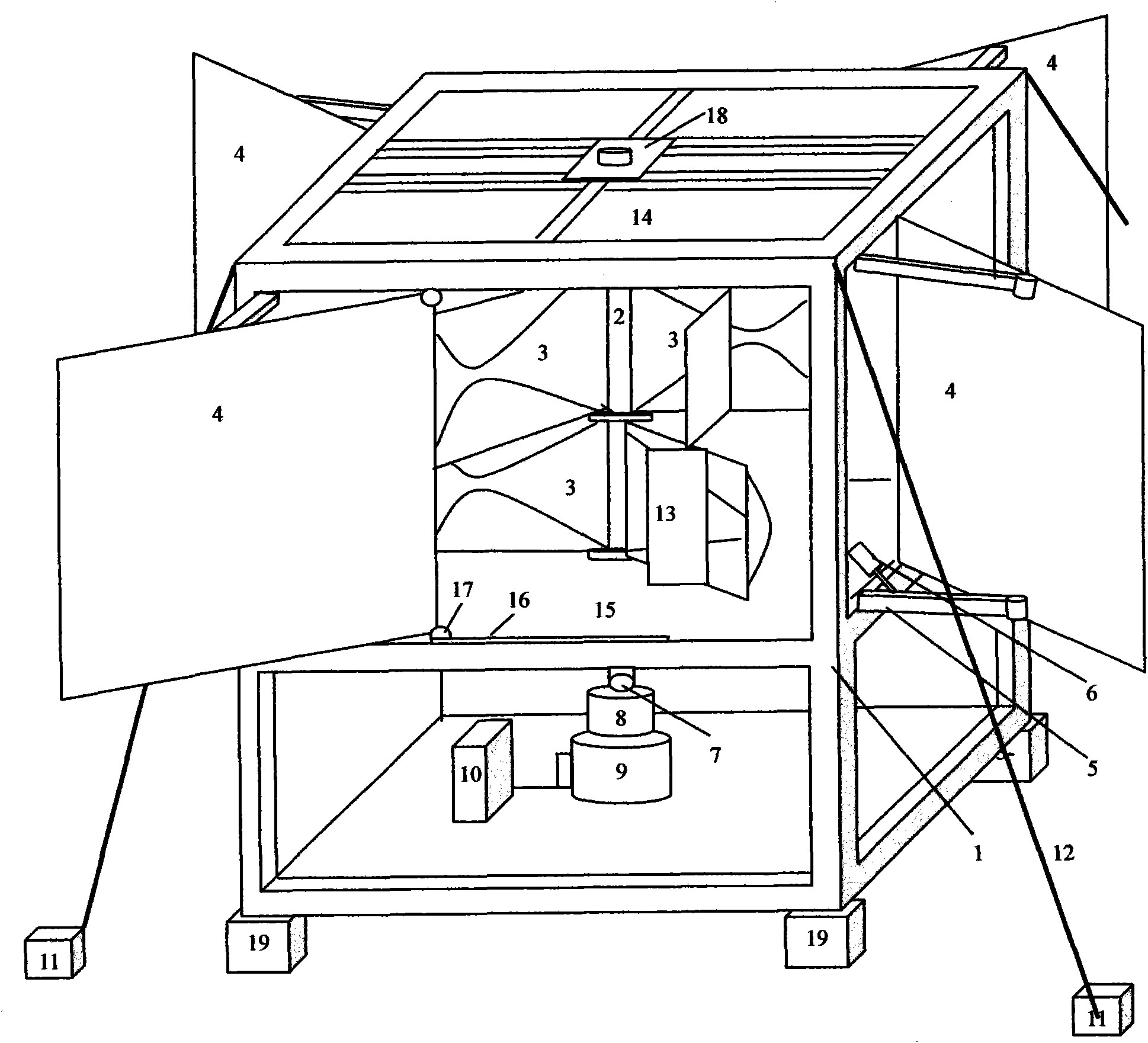

[0072] The structure of high-efficiency wind-collecting vertical wind power generation system is as follows: figure 1 As shown, the system consists of wind power system, wind collection and protection system, speed increaser system, generator system, grid-connected transformer system, and monitoring and control system.

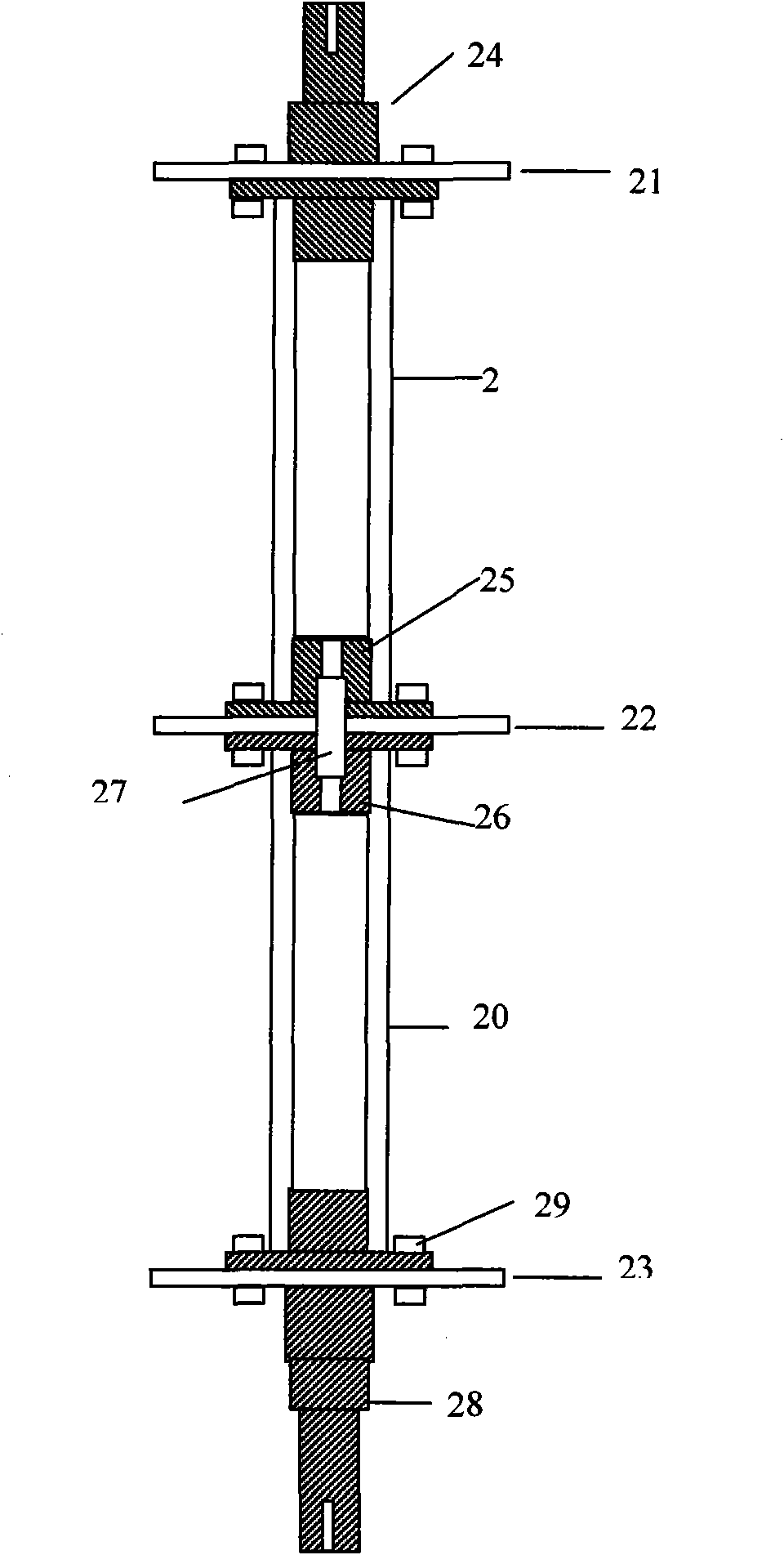

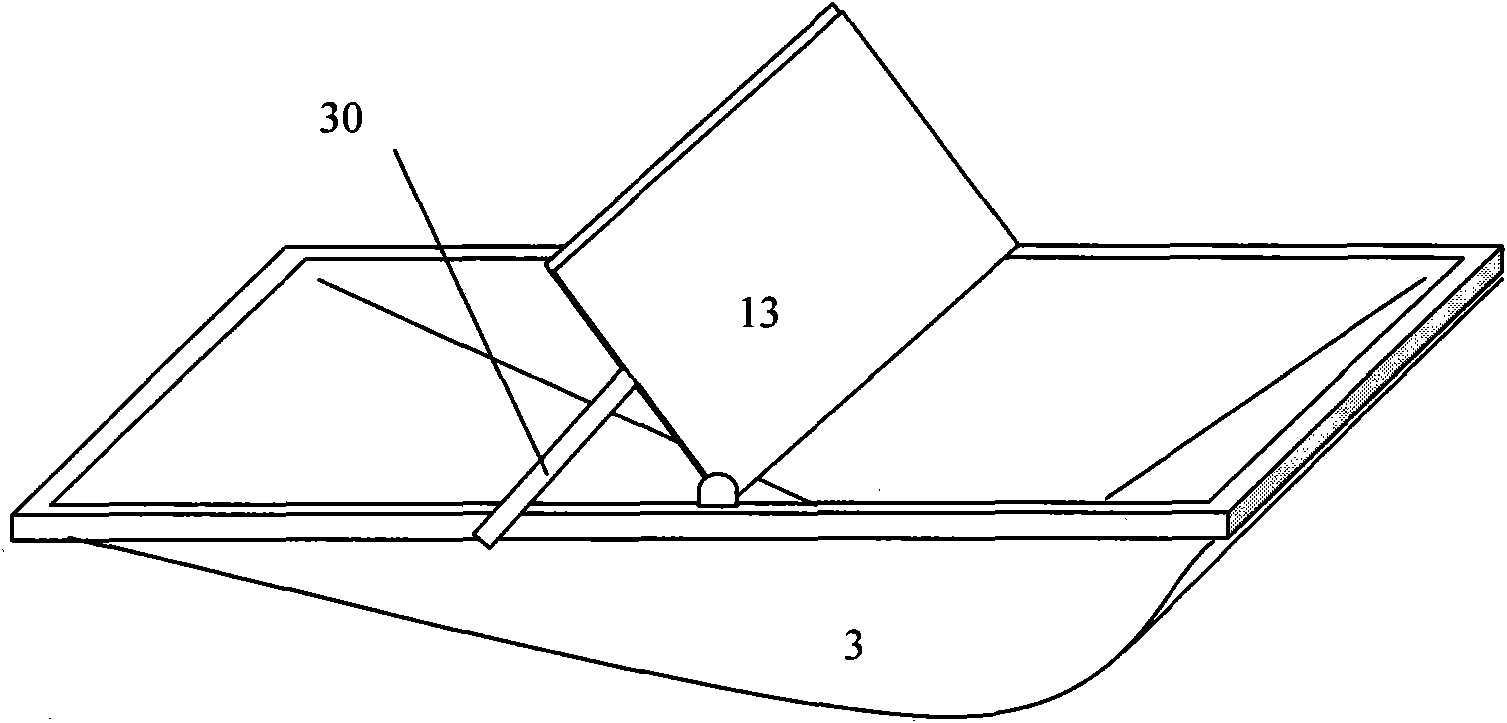

[0073] figure 1 The frame shown in 1 is the system frame; the frame of the wind turbine can be a triangular frame, or a quadrangular frame, a pentagonal frame, a hexagonal frame, an octagonal frame or a circular frame. This system uses a quadrangular frame as an example to introduce this The structure of the system. 2 is the multi-section combined fan shaft; 3 is the fan blade, 13 is the fan b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com