Device and method for checking SF6 gas leakage monitoring and alarming apparatuses

A calibration device, gas leakage technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve problems such as unrealistic, production safety hazards, protection, etc., and achieve the effect of easy portability and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

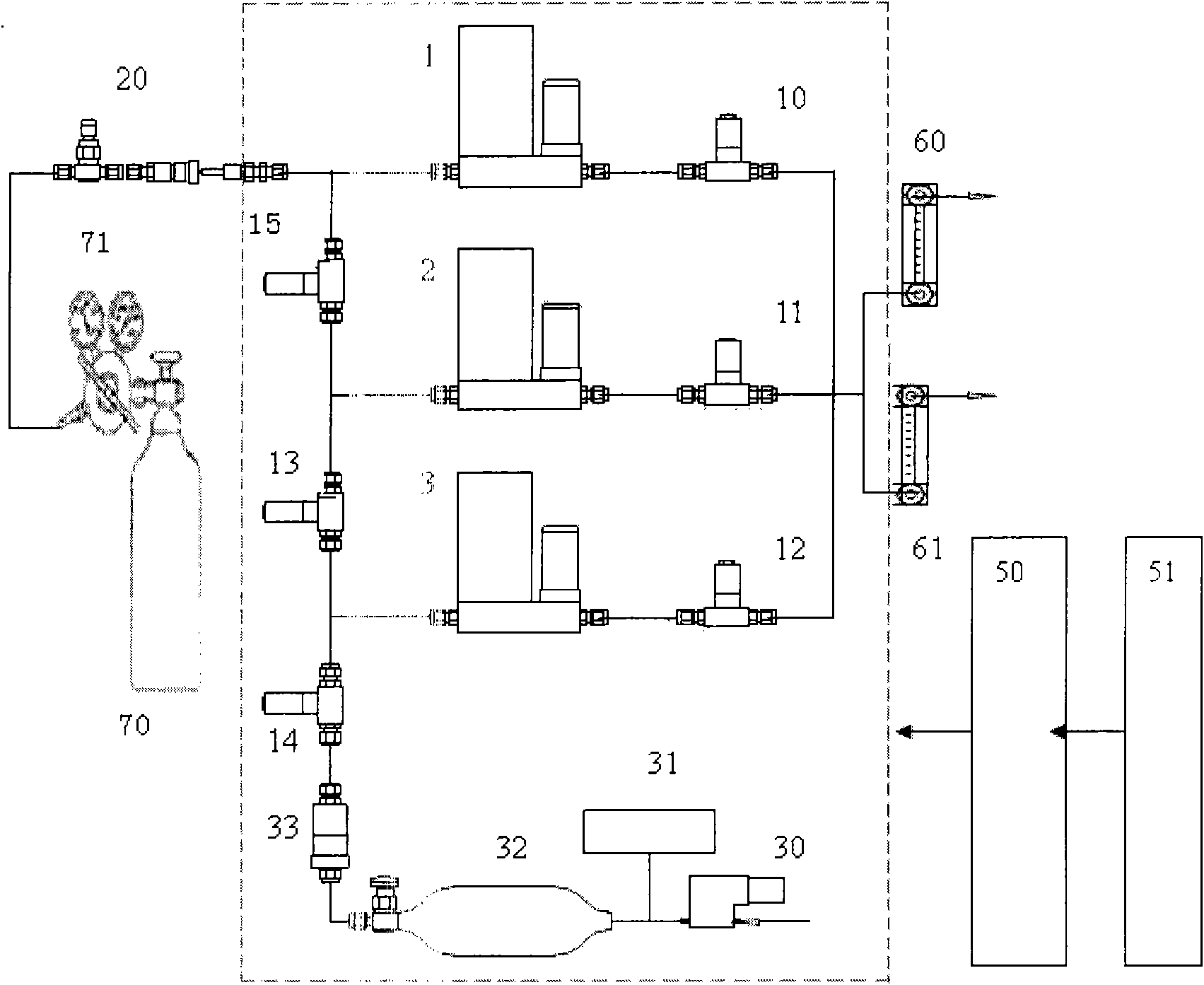

Method used

Image

Examples

Embodiment 1

[0043] SF 6 Calibration of 1500цl / l Monitoring Point of Concentration Sensor

[0044] [Output flow 1000ml / min, concentration 1500цl / l SF 6 gas]

[0045] 1. Open the concentration of 10% SF 6 The valve of the standard gas cylinder 70 and the regulating valve of the quick connector 20, adjust the SF through the pressure reducing valve 71 6 The gas pressure is 0.1MPa;

[0046] 2. Input SF on the man-machine interface 51 of the calibration device 6 The concentration value of the standard gas is 10%, and the SF that needs to be prepared 6 The gas concentration value is 1500цl / l and the output flow value is 1000ml / min, press the start button, and the micro air pump 30 starts;

[0047] 3. The control unit 50 calculates the SF according to the above input value 6 The gas distribution ratio with air is 1500цl / l: 100000цl / l [10%] = 3: 200, SF 6 The required flow rates of air and air are 15ml / min and 985ml / min respectively, and an electronic mass flowmeter with a range of 20ml / mi...

Embodiment 2

[0051] Calibration of Oxygen Concentration Sensor 15% Oxygen Concentration Monitoring Point

[0052] [Output flow rate 1400ml / min, concentration of 15% oxygen]

[0053] 1. Open the concentration of 10% SF 6 The valve of the standard gas cylinder 70 and the regulating valve of the quick connector 20, adjust the SF through the pressure reducing valve 71 6 The gas pressure is 0.1MPa;

[0054] 2. Input the oxygen concentration value in the air of 21%, the oxygen concentration value to be prepared at 15% and the output flow value of 1400ml / min on the man-machine interface 51 of the calibration device, press the start button, and the air pump 30 starts;

[0055] 3. The control unit 50 calculates air and SF based on the above input values 6 Gas distribution ratio is 15%: 21% = 5: 7, SF 6 The required flow rates of air and air are 400ml / min and 1000ml / min respectively, and according to SF 6 The size of flow rate 400ml / min automatically selects electronic mass flowmeter with a ran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com