Preparation method of high-uniformity copper-indium-gallium-selenium (CIGS) absorbed layer

A technology of copper indium gallium selenide and absorbing layer, which is applied in the field of solar power generation, and can solve problems such as huge equipment, low utilization rate of sputtering targets, and long CIGS thin film time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

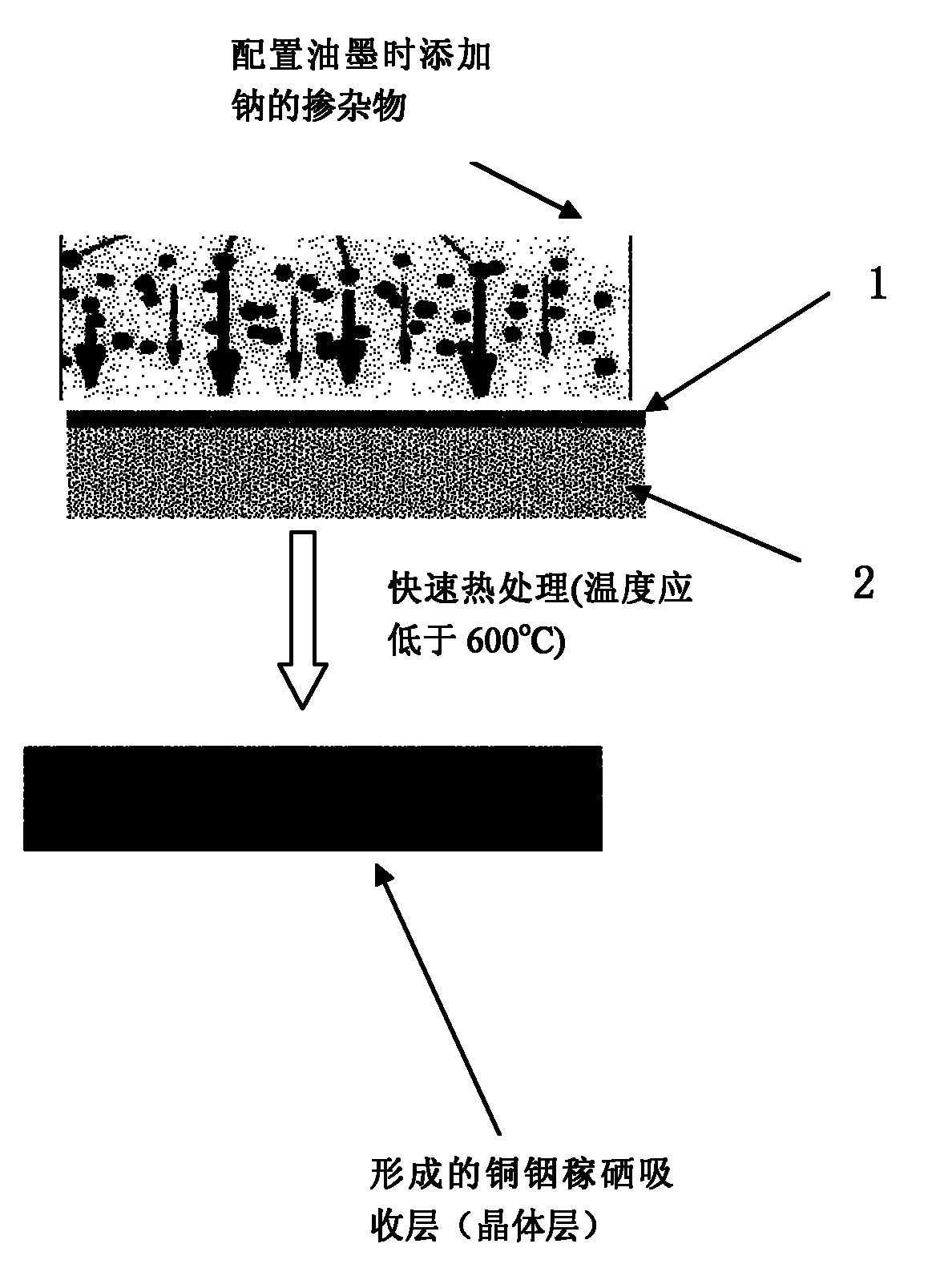

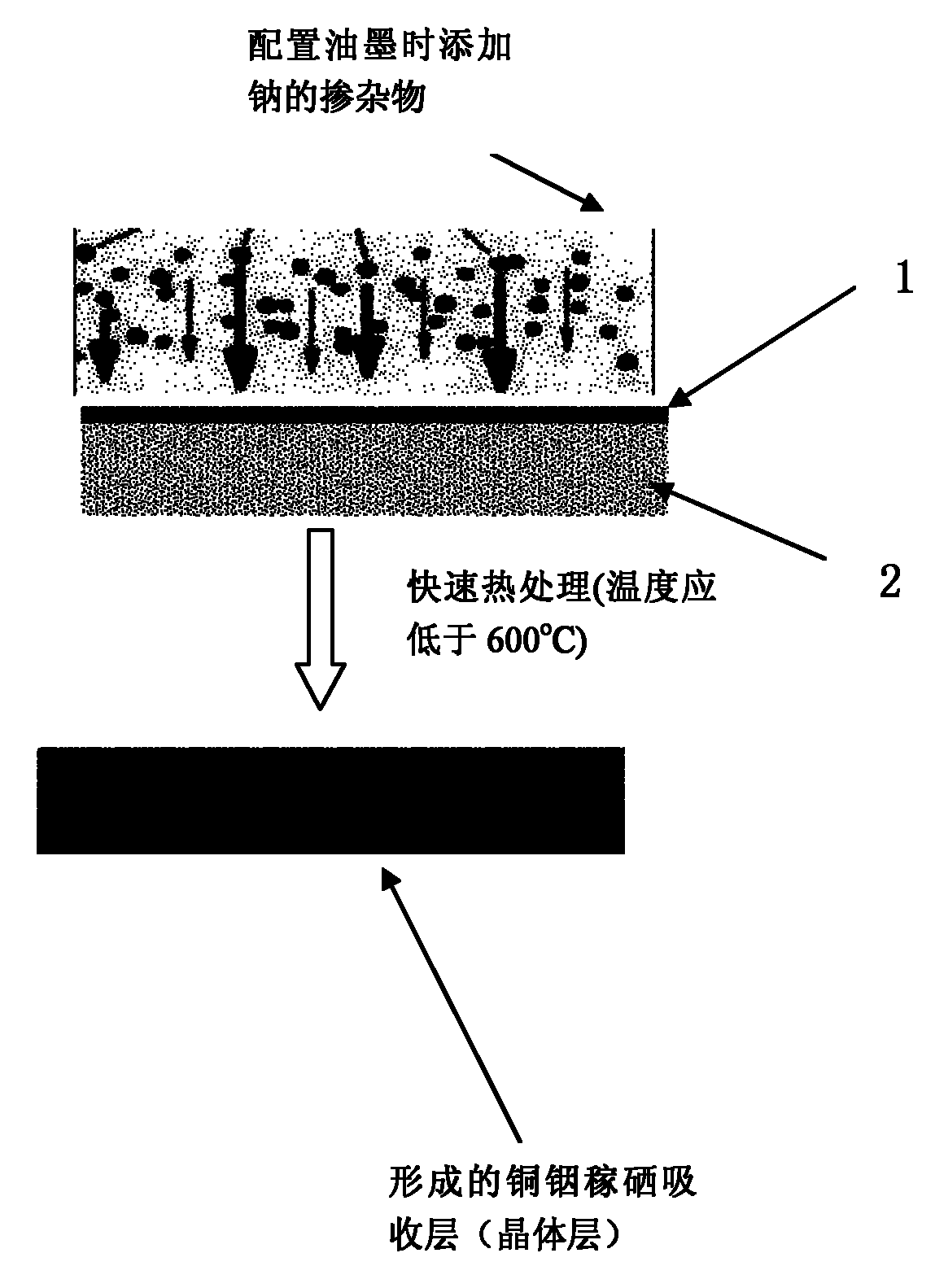

[0022] Example. A method for preparing a high-uniformity copper indium gallium selenide absorbing layer, such as figure 1 As shown, the method includes the following steps:

[0023] A. Use copper, indium, gallium and selenium nanoparticles, or copper, indium, gallium and selenium binary, ternary or quaternary alloy nanoparticles to make ink X, ink X contains copper, indium, gallium and selenium Four elements; use selenium nanoparticles to make ink Y; sodium dopant added when configuring ink X layer;

[0024] B. Spray the ink X and ink Y prepared in step A on the flexible metal film by using a simple multi-layer printing method;

[0025] C. Rapid heat treatment, melting and mixing of nanoparticles in ink X and ink Y;

[0026] D. Annealing to form a uniform copper indium gallium selenide absorptio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com