Carburization resistant metal material

A metal material, anti-carburization technology, applied in the field of metal materials, can solve the problems of unexpected C solid solution strengthening, unable to obtain high temperature strength, etc., to improve durability and operation efficiency, suppress metal dusting, and improve weldability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

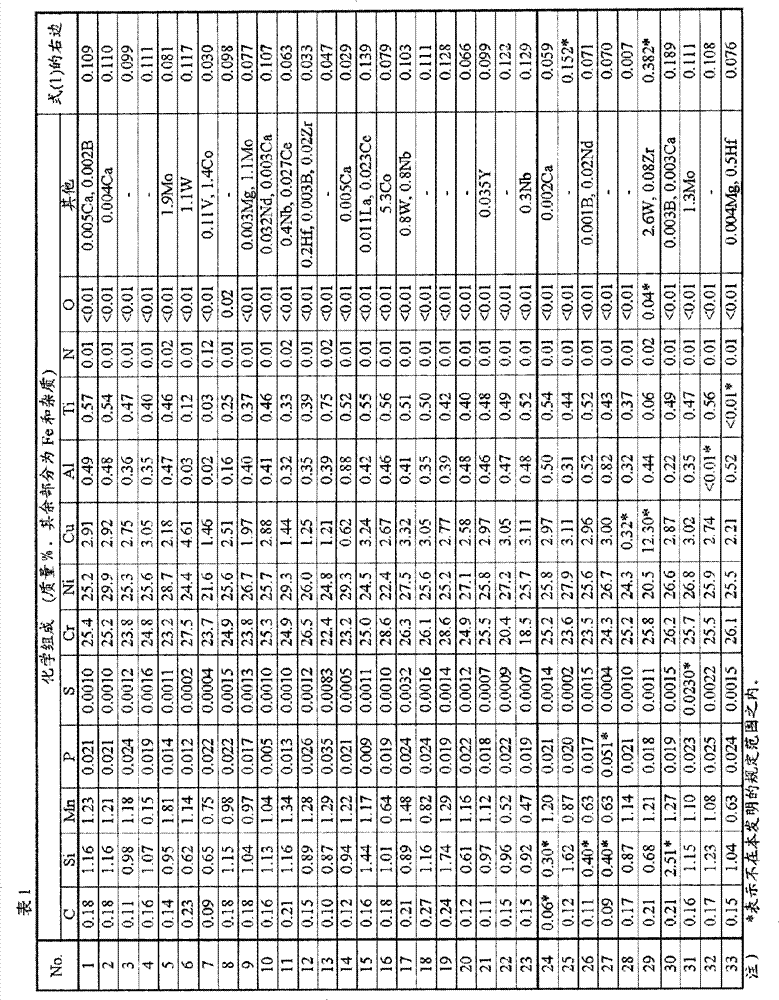

[0122] Metal materials with the chemical compositions shown in Table 1 were melted in a high-frequency heating vacuum furnace, and then hot forged and hot rolled to produce metal plates with a thickness of 6 mm. The metal plate was subjected to solution heat treatment under the condition of 1160 to 1230° C.×5 minutes, and a part of the metal plate was cut to prepare a test piece.

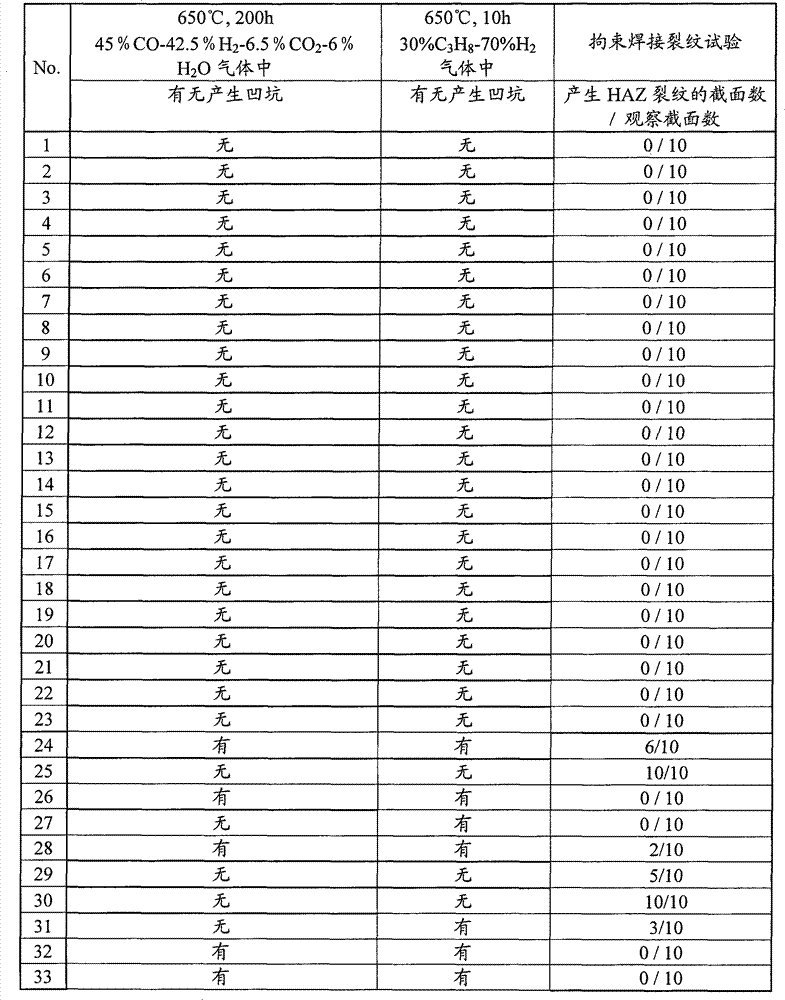

[0123] A test piece having a width of 15 mm x a length of 20 mm was cut out from the metal material described in Table 1. Place the test piece in a volume ratio of 45% CO-42.5% H 2 -6.5%CO 2 -6%H 2 It was kept isothermally at 650° C. in an atmosphere of O gas, and after 200 hours, it was taken out, and whether or not pits were formed on the surface of the test piece was judged visually and by observation with an optical microscope. The results are summarized in Table 2.

[0124]

[0125] [Table 2]

[0126]

[0127] It can be seen from Table 2 that among the metal materials Nos. 24 to 33 w...

Embodiment 2

[0129] Metal materials with the chemical compositions shown in Table 1 were melted in a high-frequency heating vacuum furnace, and then hot forged and hot rolled to produce metal plates with a thickness of 6 mm. The metal plate was subjected to solution heat treatment under the condition of 1160 to 1230° C.×5 minutes, and a part of the metal plate was cut to prepare a test piece. A test piece having a width of 15 mm x a length of 20 mm was cut out from the metal material described in Table 1. Place the test piece at 30%C by volume ratio 3 h 8 -70%H 2 In a gas atmosphere, keep isothermally at 650° C., take it out after 10 hours, and judge whether pits (pits) occur on the surface of the test piece by visual observation and optical microscope observation. The results are summarized in Table 2.

[0130] As can be seen from Table 2, among the metal materials of numbers 24 to 33 whose chemical composition does not fall into the conditions specified in the present invention, the ...

Embodiment 3

[0132] Metal materials with the chemical composition shown in Table 1 were smelted in a high-frequency heating vacuum furnace, and then hot forged and hot rolled to produce two metal plates each with a thickness of 12 mm, a width of 50 mm, and a length of 100 mm. The metal plate was subjected to solution heat treatment under the condition of 1200° C.×5 minutes, and a part of the metal plate was cut to prepare a test piece.

[0133] Next, after performing V-shaped groove processing at an angle of 30° and a root thickness of 1.0mm on one side of the longitudinal direction of the above-mentioned test piece, using "DNiCrMo-3" specified in JIS Z3224 (1999) as an electrode, the thickness of 25mm, A commercially available metal plate of "SM400C" specified in JIS G 3106 (2004) having a width of 150 mm and a length of 150 mm was subjected to restraint welding on the four sides. Then, using "YNiCrMo-3" TIG welding wire specified in JIS Z3334 (1999), multilayer welding was performed in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com