Preparation method of phase-change energy-storage microcapsule

A phase-change energy storage and microcapsule technology, which is applied in the field of preparation of phase-change energy storage microcapsules, can solve the problems of difficulty in preparation, toxicity, and unfavorable industrial production, and achieves easy preparation, high phase transition enthalpy, and high efficiency. Beneficial for industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The invention discloses a preparation method of phase change energy storage microcapsules, comprising:

[0032] Provide first emulsion, described first emulsion takes paraffin as dispersed phase, takes chitosan aqueous solution as continuous phase;

[0033] Dispersing the primary emulsion in an external oil phase to obtain a double emulsion, the external oil phase being liquid paraffin;

[0034] A cross-linking agent is added to the double emulsion to carry out a cross-linking reaction to obtain phase-change energy storage microcapsules, and the cross-linking agent is glutaraldehyde.

[0035] According to the present invention, the first emulsion of described chitosan solution coating paraffin is preferably prepared according to the following method:

[0036] Chitosan is dissolved in an acidic aqueous solution to obtain a first solution,

[0037] The first solution is heated, and paraffin wax is added dropwise into the first solution for emulsification to obtain an in...

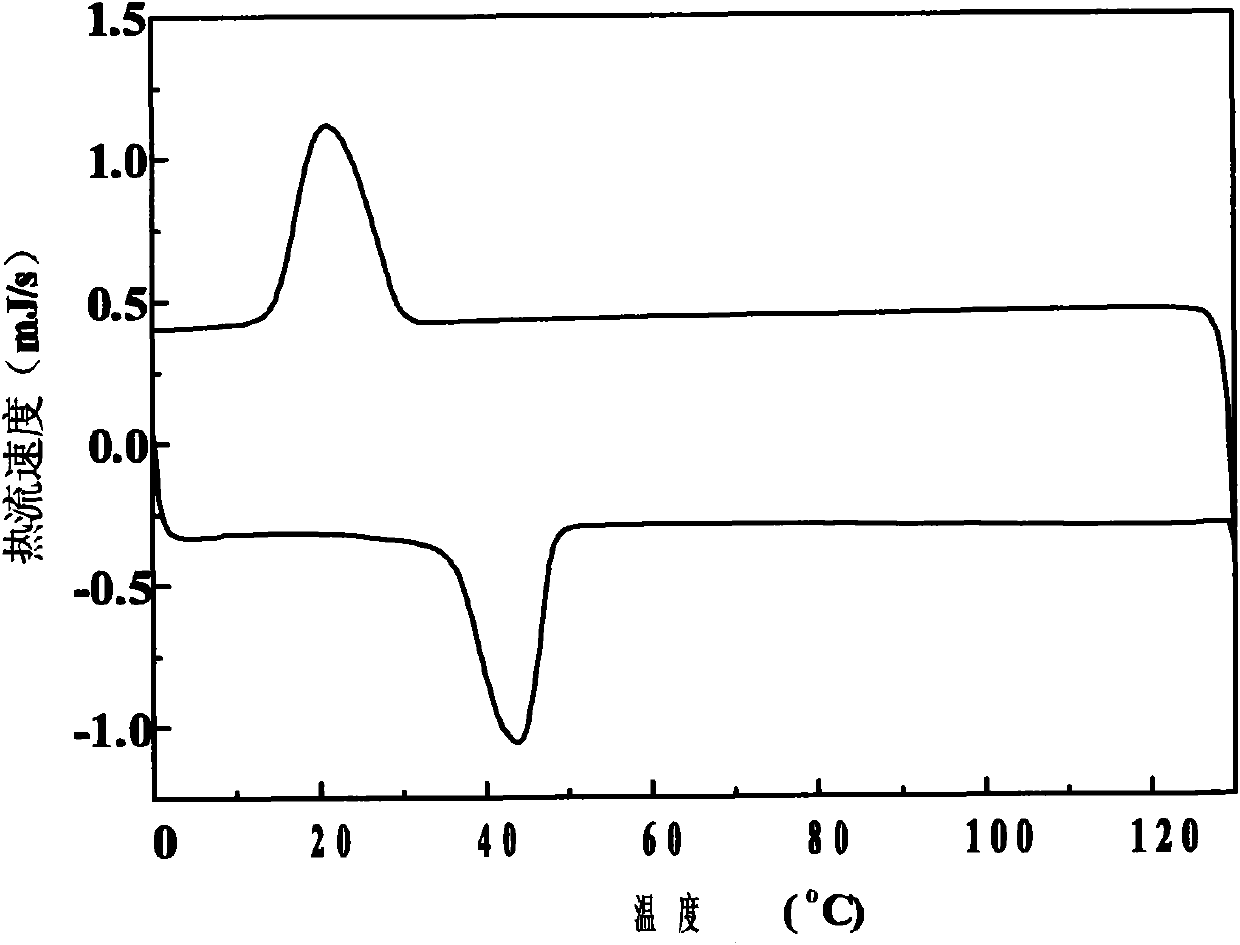

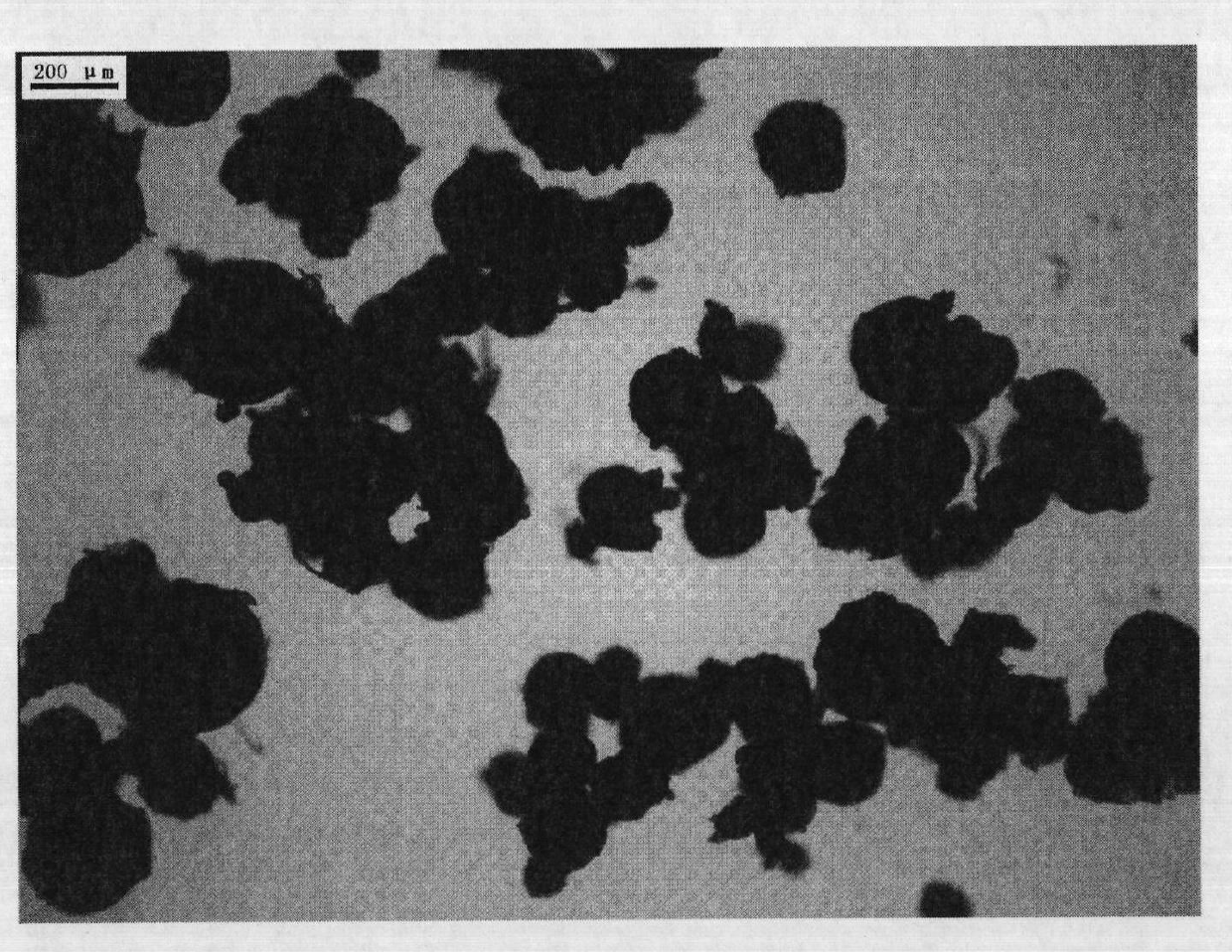

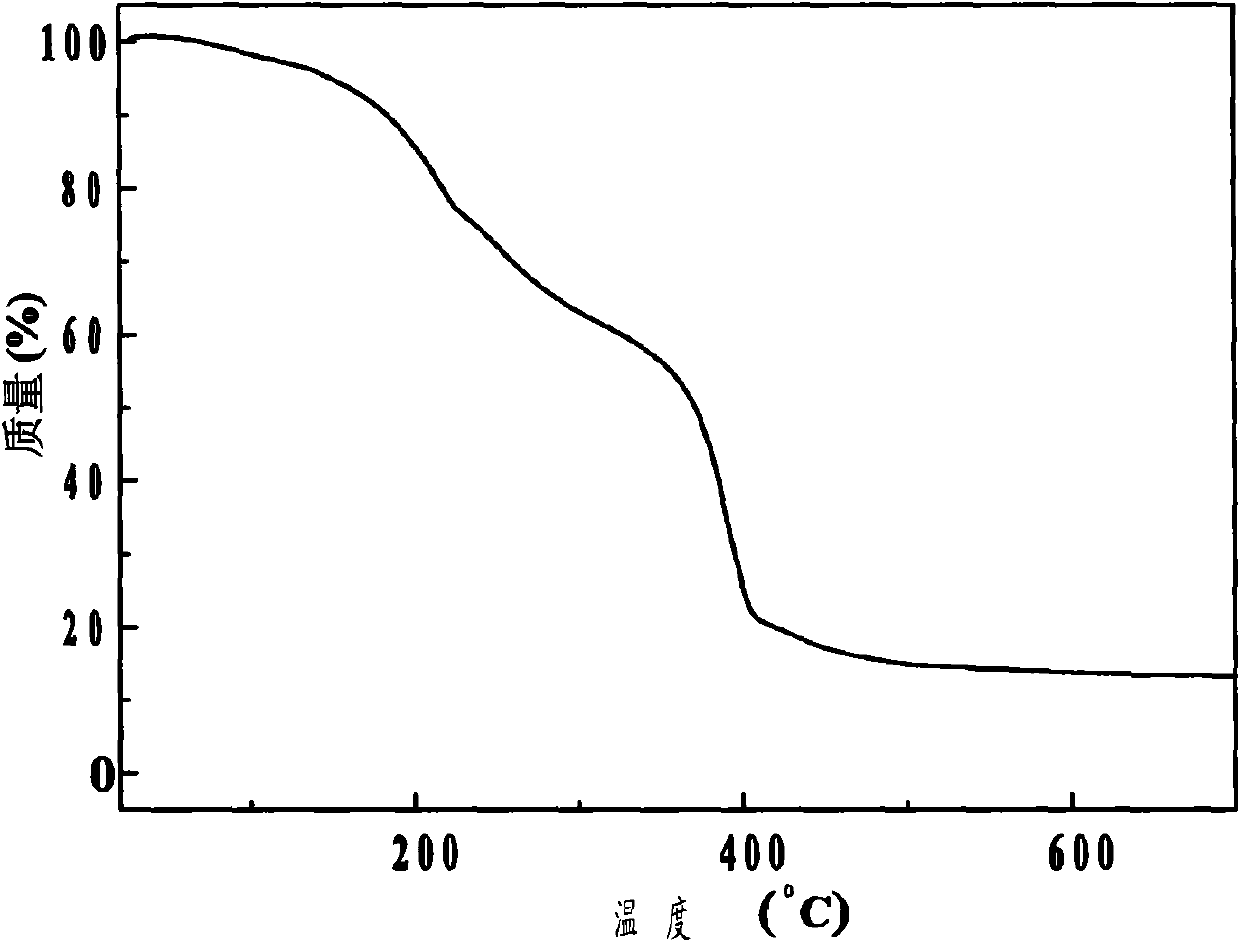

Embodiment 1

[0047] Dissolve 3g of chitosan with a deacetylation degree of 85% in 200mL of an aqueous solution containing 0.5wt% acetic acid, heat the chitosan aqueous solution to 45°C, melt 10mL of paraffin wax with a melting point of 39°C and add it dropwise to the shell In the polysaccharide aqueous solution, keep stirring at a speed of 1400 rpm for 3 hours to fully emulsify, and finally obtain a white viscous liquid, namely the primary emulsion;

[0048] 50 mL of the prepared primary emulsion was added dropwise to 200 mL of span80 liquid paraffin and stirred for 3 hours to obtain a double emulsion;

[0049] Slowly add the glutaraldehyde aqueous solution of 5g 25wt% in double emulsion afterwards and carry out cross-linking reaction, along with the carrying out of cross-linking reaction, reactant turns yellow gradually, after color no longer changes, cross-linking reaction finishes, and product is removed from reaction Take it out from the container, filter it with suction, wash it with ...

Embodiment 2

[0054] Dissolve 3g of chitosan with a deacetylation degree of 85% in 200mL of an aqueous solution containing 0.5wt% acetic acid, heat the chitosan aqueous solution to 45°C, melt 10mL of paraffin wax with a melting point of 39°C and add it dropwise to the shell In the polysaccharide aqueous solution, keep stirring at a speed of 2100 rpm for 3 hours to fully emulsify, and finally obtain a white viscous liquid, namely the primary emulsion;

[0055] 50 mL of the prepared primary emulsion was added dropwise to 200 mL of span80 liquid paraffin and stirred for 3 hours to obtain a double emulsion;

[0056] Slowly add the glutaraldehyde aqueous solution of 5g 25wt% in double emulsion afterwards and carry out cross-linking reaction, along with the carrying out of cross-linking reaction, reactant turns yellow gradually, after color no longer changes, cross-linking reaction finishes, and product is removed from reaction Take it out from the container, filter it with suction, wash it with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com