Preparation method of triangular silver nanosheet

A technology of triangular silver and nanosheets, which is applied in the field of preparation of triangular silver nanomaterials, can solve problems such as complicated operation, and achieve the effects of simple operation, low production cost and rapid production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

[0020] The preparation method of the triangular silver nanosheet of the present embodiment has the following steps:

[0021] ① Silver nitrate (AgNO 3 ), trisodium citrate (Na 3 C 6 h 5 o 7 2H 2 O) and polyvinylpyrrolidone (PVP), these three reagents were mixed in a molar ratio of 2:30:1, and stirred for 5 min at a temperature of 10°C. The solution at this time is colorless, the solution is silver nitrate (AgNO 3 ), trisodium citrate (Na 3 C 6 h 5 o 7 2H 2 O) and polyvinylpyrrolidone (PVP) mixed system.

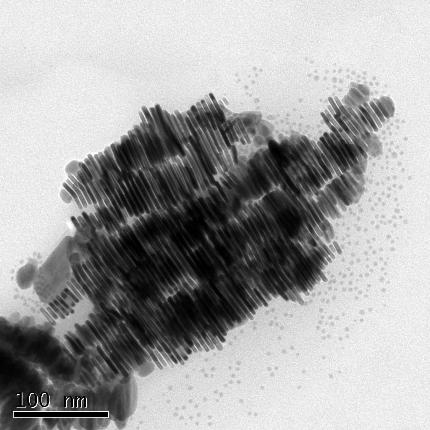

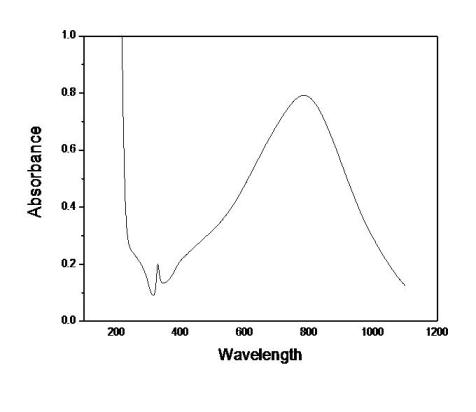

[0022] ②Quickly add an appropriate amount of sodium borohydride (NaBH 4 ) reagent is added to the mixed system obtained in step ①, so that silver nitrate (AgNO 3 ) with sodium borohydride (NaBH 4 ) to form a reduction reaction of round silver nanoparticles, the ratio of the molar amount of sodium borohydride reagent to the molar amount of polyvinylpyrrolidone is 0.1, and the solution at this time appears bright yellow, that is, the size of the silver nanoparticle...

Embodiment 2)

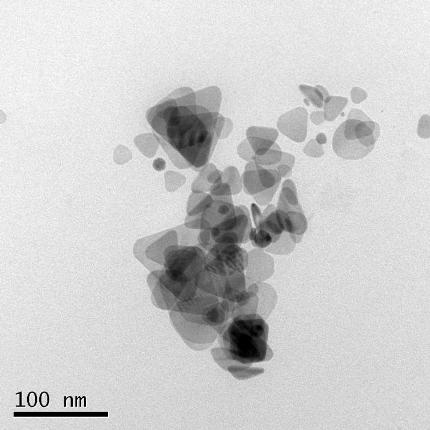

[0025] The remainder of the preparation method of the triangular silver nanosheets of this embodiment is the same as in Example 1, except that sodium borohydride (NaBH 4 ) The molar addition amount is 0.12 times of the polyvinylpyrrolidone molar dosage. The total amount of molar addition of hydrogen peroxide is 0.8 times of the molar amount of polyvinylpyrrolidone, and the stirring time of successively adding hydrogen peroxide is extended by 2 minutes. Finally, triangular silver nanosheets with a size of 60nm-70nm and some round particles are obtained.

Embodiment 3)

[0027] The rest of the preparation method of a triangular silver nanosheet of the present embodiment is the same as in Example 1, except that sodium borohydride (NaBH 4 ) molar addition is 0.1 times the molar dosage of polyvinylpyrrolidone. The total amount of molar addition of hydrogen peroxide is 0.9 times of the molar amount of polyvinylpyrrolidone, and the stirring time of successively adding hydrogen peroxide is extended by 4 minutes. Finally, triangular silver nanosheets with a size of 70nm-80nm and some round particles are obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com