Method for preparing composite worm or bearing bush

A technology of composite bearing bush and worm wheel, applied in the field of worm wheel and bearing bush, can solve the problems of reducing the structure size of the worm wheel, low impact strength, poor wear resistance, etc., and achieve the effects of short pulse time, enhanced bearing capacity, and less welding heat.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

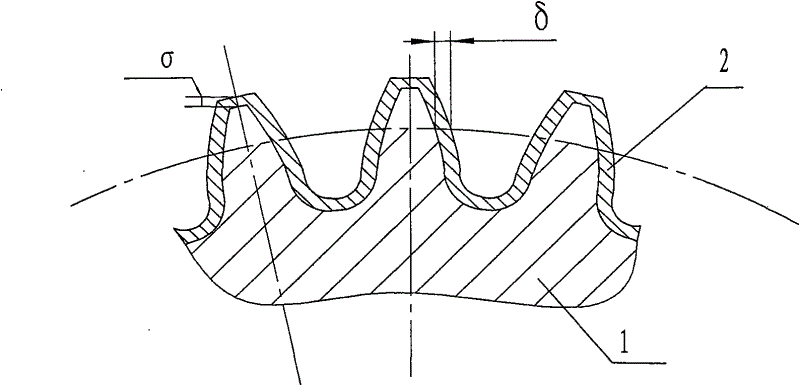

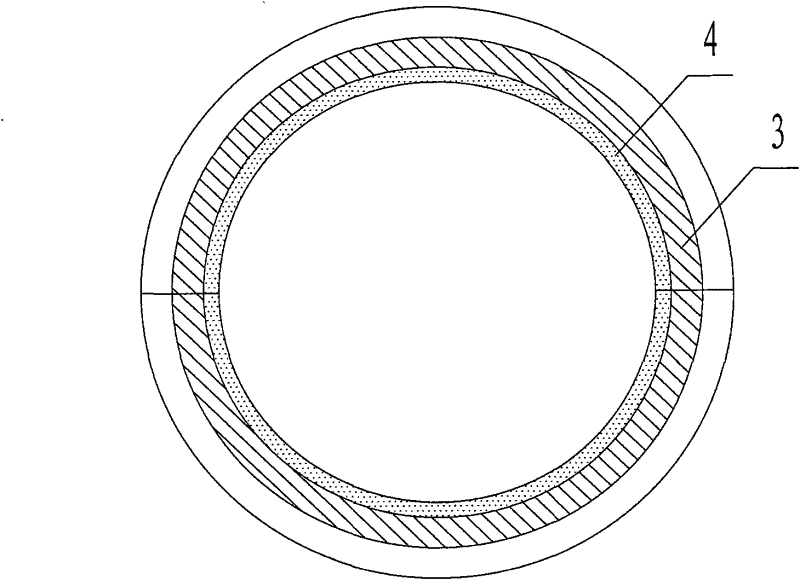

[0032] In the present invention, nodular iron and low carbon steel are used to make the worm wheel parent body 1 or the bearing bush parent body 3, and the worm wheel parent body or the bearing bush parent body is processed to the required size, and a welding layer margin is reserved. Using sub-laser pulse welding, pulse argon arc welding or laser pulse cluster fusion welding, the copper alloy welding wire is welded to the surface of the matrix 1 to produce a worm wheel blank covered with a uniform and dense welding layer on the surface of the matrix. Through high-temperature tempering and aging treatment, the structure is promoted to be uniform, and the internal stress is eliminated. Then, the forming cutter is used to adjust the cutter teeth to the middle position of the two teeth, and mill to the required size. The welding layer at the root of the tooth can choose a small value, and the thickness is selected as the modulus * (0.1 ~ 0.35) mm; the thickness of the welding laye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com