Large area fluorescent concentrator solar cell system

A solar cell and large-area technology, applied in the field of solar power generation, can solve the problems of increasing processing costs, difficulty reducing glass thickness, increasing glass size, etc., to reduce material and processing costs, save material and processing costs, reduce double-sided spotlight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings, but the present embodiments are not intended to limit the present invention, and any similar structures and similar changes of the present invention should be included in the protection scope of the present invention.

[0033] A large-area fluorescent concentrating solar cell system and its manufacturing method provided by the present invention are characterized in that they include:

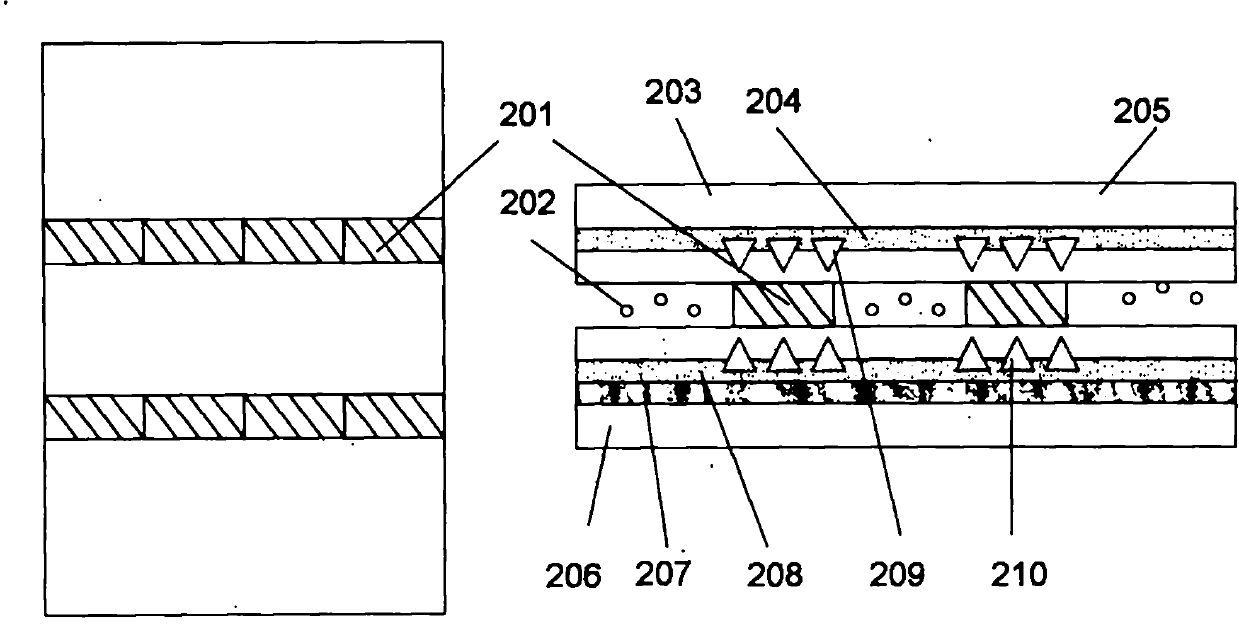

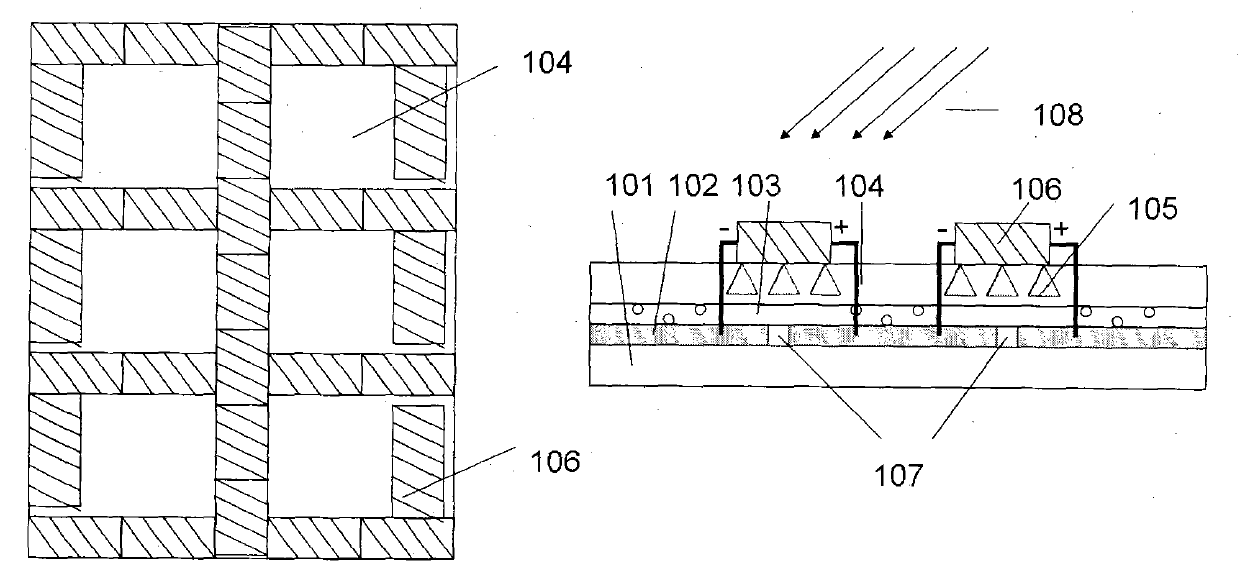

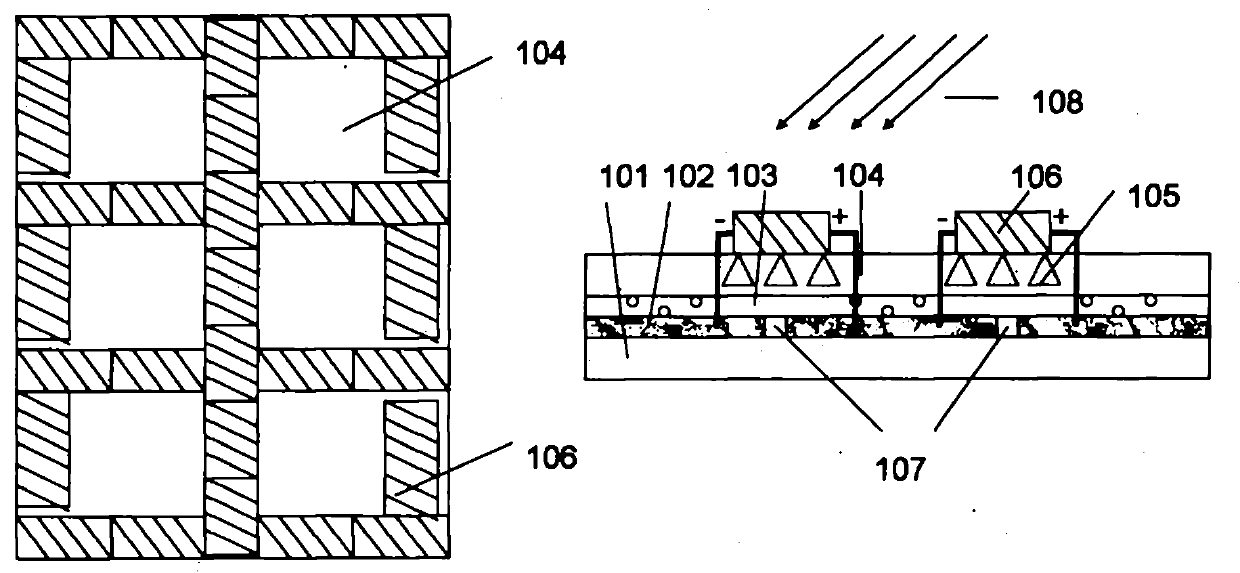

[0034] Solar cells with high conversion efficiency such as monocrystalline silicon and their combined light-receiving surfaces are encapsulated on the light guide plate of the fluorescent concentrator by glue;

[0035] One of the fluorescent concentrators is composed of a substrate, containing or not containing a metal reflective layer, a luminescent film and a light-guiding film; the light-guiding plate preferably utilizes a mold with a microstructure formed by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com