Electrode element, method of manufacturing electrode element, and lithium ion secondary battery

A technology of electrode components and positive electrodes, applied in the field of electrode components, can solve problems such as damage reduction, interface resistance, difficult to solve, and easy peeling of the surface coating layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

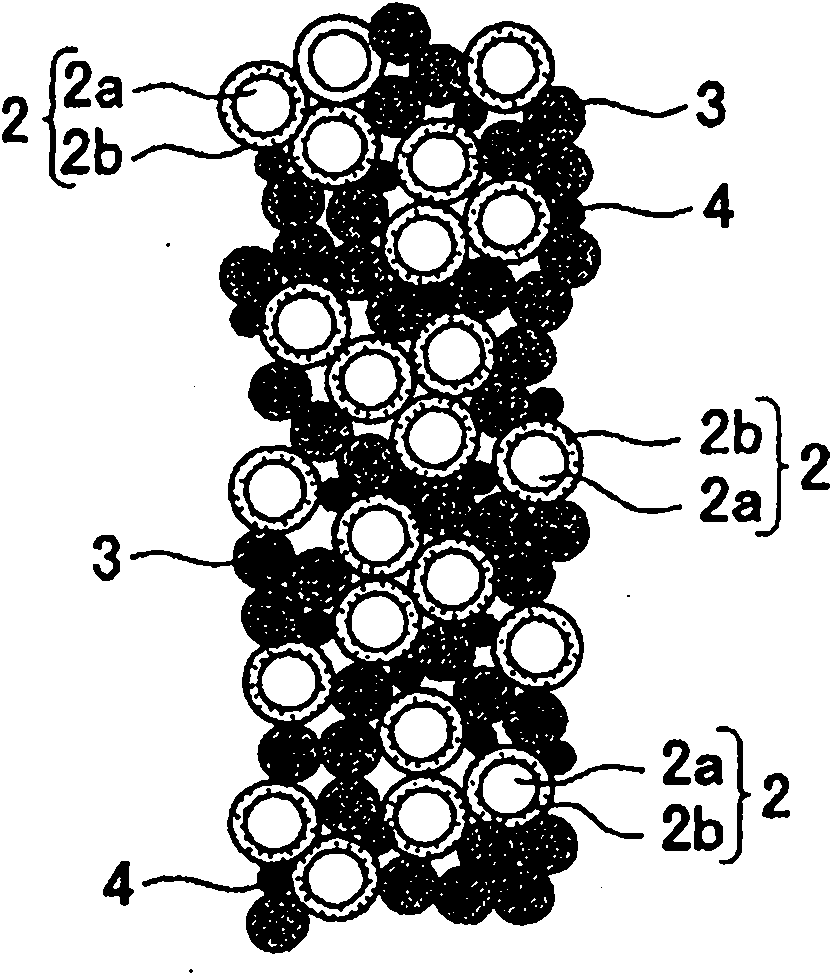

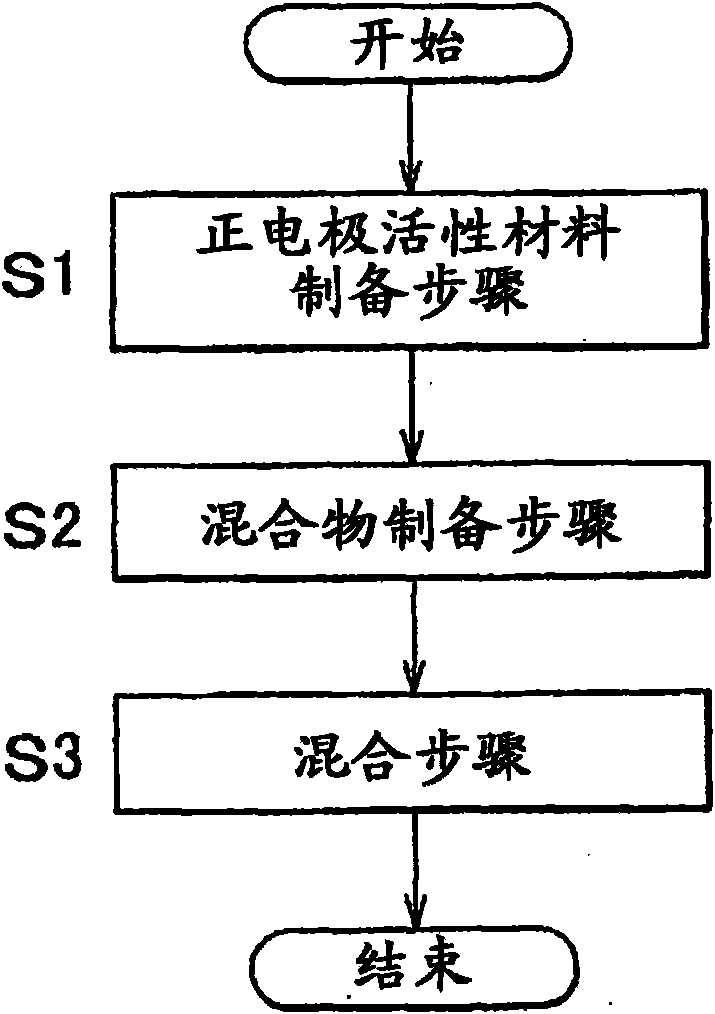

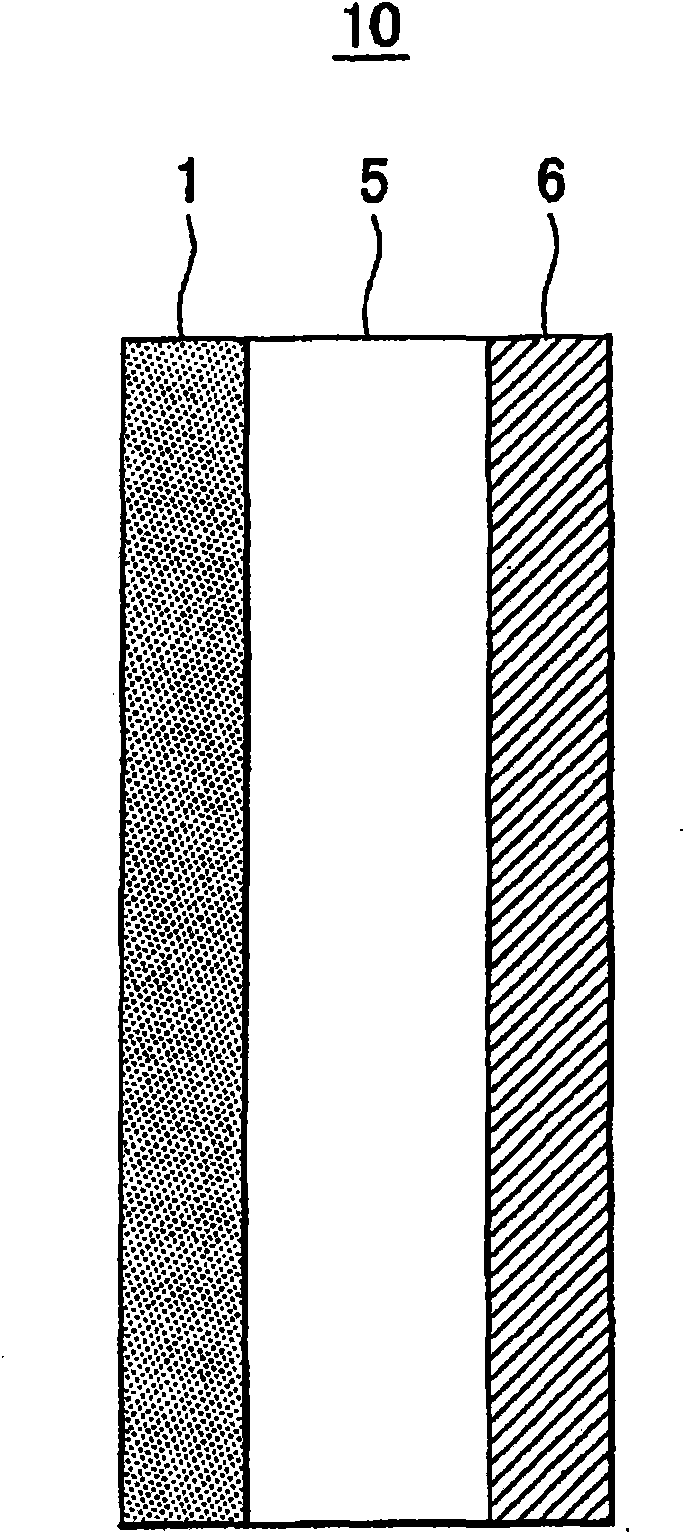

[0069] Dissolve equimolar LiOC in ethanol solvent 2 H 5 And Nb(OC 2 H 5 ) 5 To prepare the composition, and spray the composition to coat LiCoO using a rotary and flow coating machine (SFD-01 manufactured by Powrex Corporation) 2 s surface. Afterwards, the coated LiCoO was treated at atmospheric pressure and a temperature of 400°C 2 Heat treatment for 30 minutes to 2 (Active material) LiNbO is formed on the surface 3 Layer (coating layer), thereby preparing a positive electrode active material (having an average particle diameter of 10 μm, and the same applies to the following positive electrode active materials). Subsequently, the prepared positive electrode active material and solid electrolyte (Li 7 P 3 S 11 , 7μm average particle diameter, and the same applies to the following solid electrolyte) was placed in a screw bottle, and mixed using a shaker (manufactured by Shibata Scientific Technology, Ltd.) during 10 seconds to prepare Powder element (hereinafter, referred to as ...

no. 2 example

[0071] The prepared positive electrode active material was mixed with a solid electrolyte during five minutes using a spatula to prepare a powder element (hereinafter, referred to as "powder element of the second example"), and, in addition, used with the first The battery of the example has similar manufacturing steps and materials to manufacture the battery of the second example.

no. 3 example

[0087] Using a mortar, 1.5 mg of a conductive agent (vapor-grown carbon fiber, also applicable to the following conductive agent) was mixed with 5.3 mg of a solid electrolyte to prepare a mixture, and 0.8 mg of a positive electrode prepared by a method similar to that of the powder element of the first example was prepared. The electrode active material and the mixture were placed in a screw bottle, and they were mixed during 10 seconds using an oscillator to prepare a powder element (hereinafter, referred to as "powder element of the third example"). Then, a positive electrode layer was prepared using the powder element of the third example, and, except for this, a secondary battery was manufactured in the same manner as in the case of the battery of the first example (hereinafter, referred to as "the battery of the third example").

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| shear load | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com