Method and device for removing odorous gas

A malodorous gas and purpose technology, which is applied in the field of efficient removal of malodorous gas, can solve problems such as operation maintenance and management troubles, long time removal of stench, and practical industrial application limitations, etc., to achieve easy use and maintenance, avoid instability, eliminate The effect that the odor efficiency is high

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 1) dissolving ferrate in a KOH aqueous solution with a concentration of 15M to obtain a saturated solution of ferrate;

[0024] 2) Soak granular activated carbon with a particle size of 300 meshes in the above solution, and the mass ratio of ferrate to activated carbon is 10:1;

[0025] 3) Stir slowly for 2 hours and let it stand overnight to ensure that the activated carbon fully absorbs ferrate;

[0026] 4) After filtering, the solid is air-dried naturally.

[0027] 5) The above-mentioned activated carbon loaded with ferrate and 50 mesh activated carbon are mixed uniformly at a ratio of 1:1 to prepare a composite filter material;

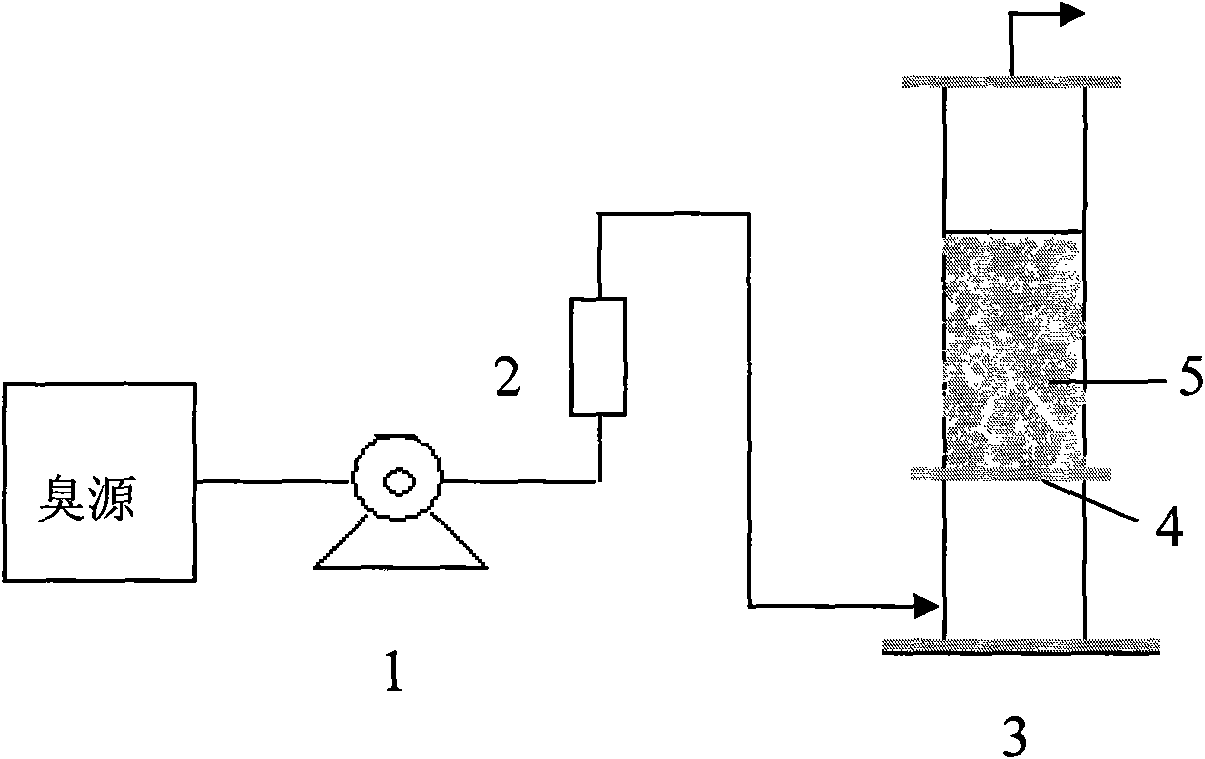

[0028] 6) A filter tower made of plexiglass (inner diameter 52mm, height 353mm), see figure 1 . The filter tower 3 is filled with the above-mentioned composite filter material. The filling volume is 0.32L, the filling height is 18cm, and the filling density is 342.3g / L. The hydrogen sulfide gas is passed through the gas flow meter 2 fr...

Embodiment 2

[0030] 1) dissolving ferrate in a KOH aqueous solution with a concentration of 15M to obtain a saturated solution of ferrate;

[0031] 2) Soak granular zeolite with a particle size of 500 mesh in the above solution, and the mass ratio of ferrate to zeolite is 12:1;

[0032] 3) Stir slowly for 2 hours, and let it stand overnight to ensure that the zeolite fully absorbs ferrate;

[0033] 4) After filtering, the solid is air-dried naturally.

[0034] 5) The above-mentioned zeolite loaded with ferrate and 10-mesh activated carbon are mixed uniformly at a ratio of 1:1 to prepare a composite filter material;

[0035] 6) A filter tower made of plexiglass (inner diameter 52mm, height 353mm), see figure 1 . The filter tower 3 is filled with the above-mentioned composite filter material. The filling volume is 0.32L, the filling height is 18cm, and the filling density is 342.3g / L. Pass the ammonia gas from the blower 1 through the gas flow meter 2 respectively, at a rate of 50m 3 T...

Embodiment 3

[0037] 1) dissolving ferrate in a KOH aqueous solution with a concentration of 15M to obtain a saturated solution of ferrate;

[0038] 2) Soak granular activated carbon with a particle size of 400 meshes in the above solution, and the mass ratio of ferrate to activated carbon is 11:1;

[0039] 3) Stir slowly for 2 hours and let it stand overnight to ensure that the activated carbon fully absorbs ferrate;

[0040] 4) After filtering, the solid is air-dried naturally.

[0041] 5) The above-mentioned activated carbon loaded with ferrate and ceramsite of 30 meshes are mixed uniformly at 1:1 to prepare a composite filter material;

[0042] 6) A filter tower made of plexiglass (inner diameter 52mm, height 353mm), see figure 1 . The filter tower 3 is filled with the above-mentioned composite filter material. The filling volume is 0.32L, the filling height is 18cm, and the filling density is 342.3g / L. Taking domestic garbage from a garbage compression station in Ningbo as the sou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com