Device for preparing bio-oil from waste manmade boards by thermochemical clean conversion

A thermochemical and bio-oil technology, which is applied in the preparation of biofuels, liquid hydrocarbon mixtures, and the petroleum industry, can solve the problems of ineffective removal of harmful pollutants, negative impacts of subsequent use of bio-oil, and failure of gas to meet emission standards. To achieve the effect of compact structure, simple structure and reduced manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

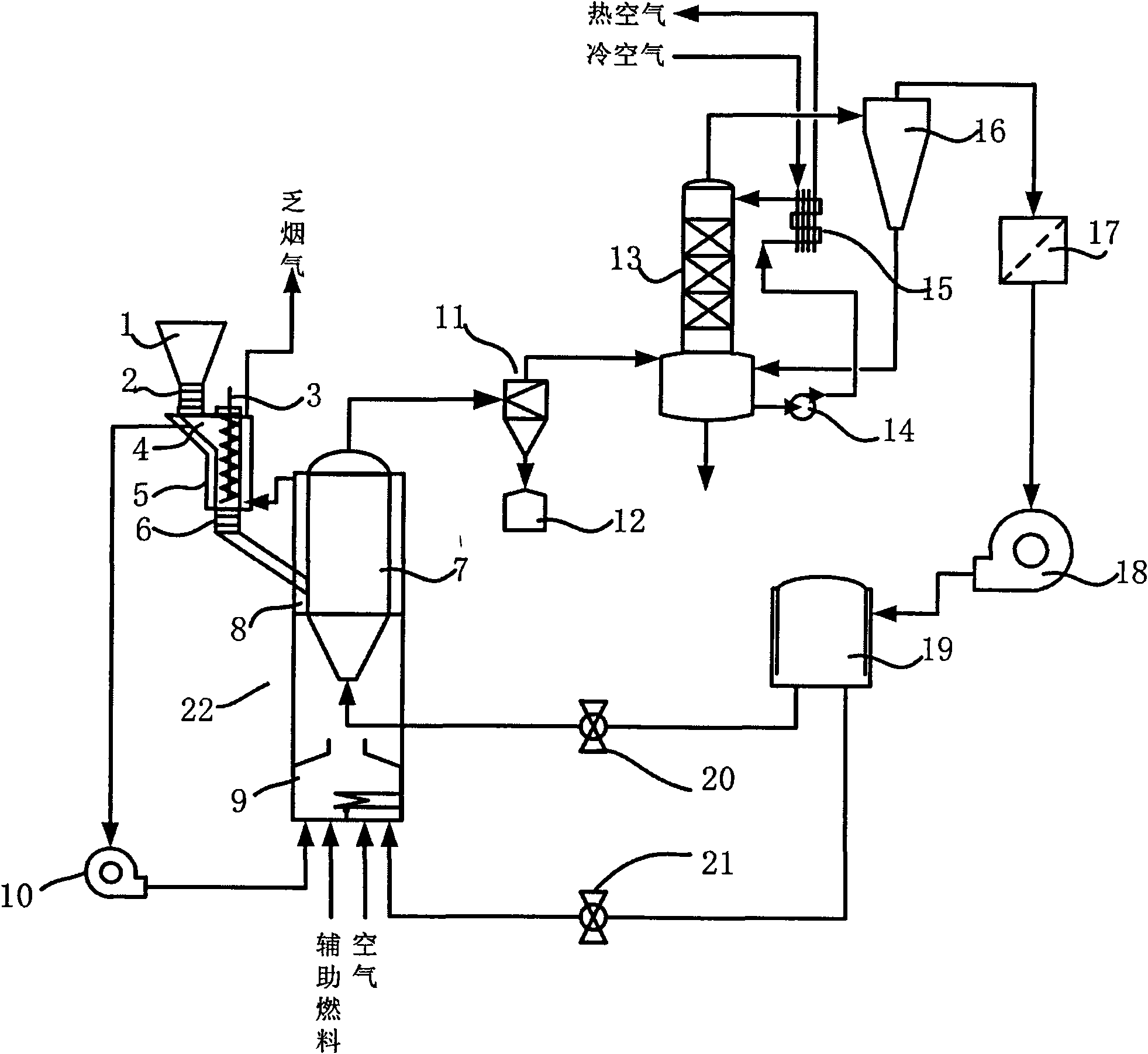

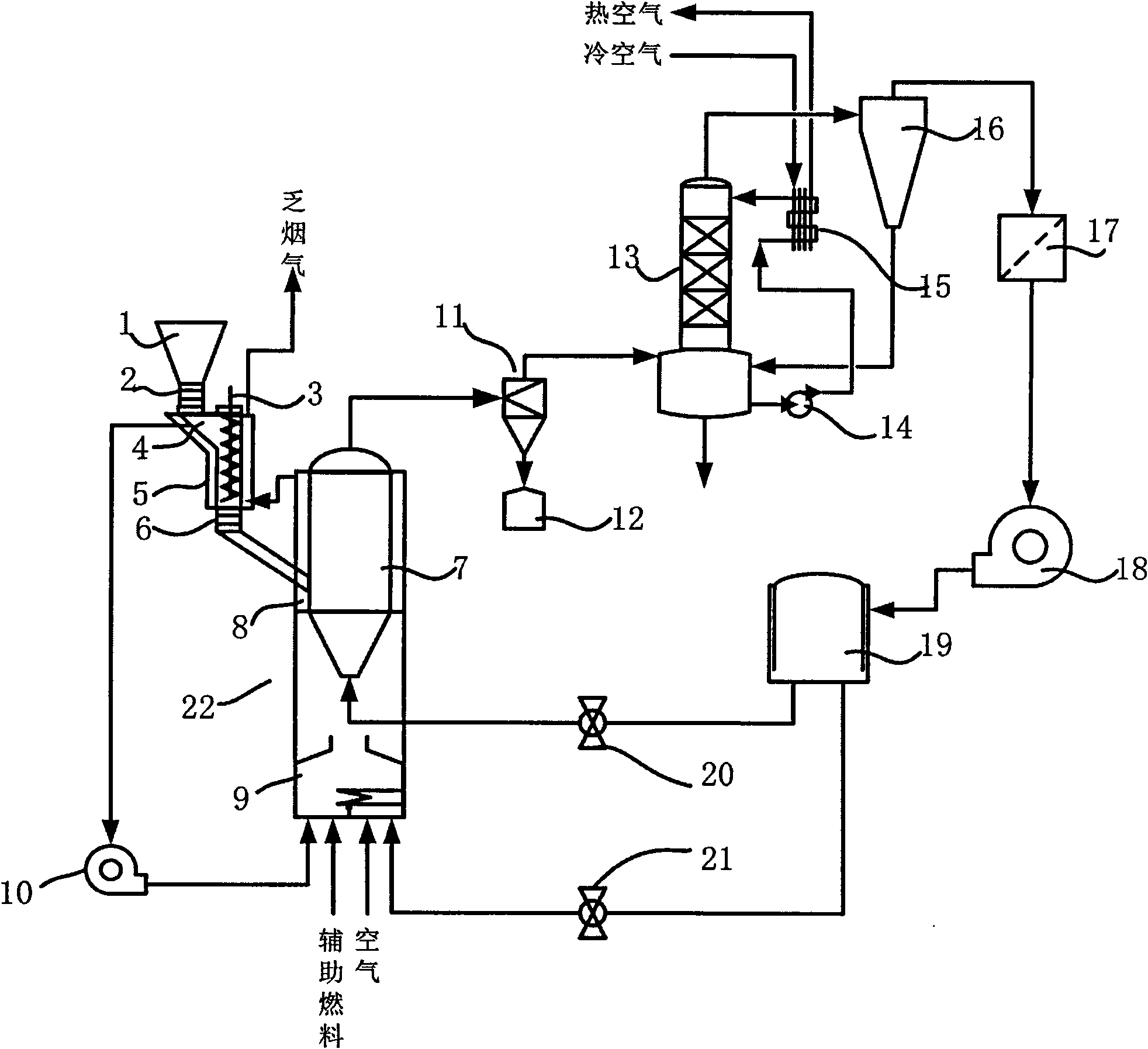

[0016] The device for preparing bio-oil by thermochemical cleaning and conversion of waste wood-based panels proposed by the present invention has the following structure: figure 1 As shown, it includes feed bin 1, pre-pyrolyzer 4, main pyrolyzer 22, gas-solid separator 11, condenser 13, heat exchanger 15, hydrocyclone 16, electrostatic precipitator 17 and gas distributor 19. The feed bin 1 communicates with the upper part of the pre-pyrolyzer 4, and the upper air-closing device 2 is arranged between the feed bin 1 and the pre-pyrolyzer 4, and the lower part of the pre-pyrolyzer 4 is connected to the main pyrolyzer 22 through a pipeline. connected. The pre-pyrolyzer 4 is provided with a screw feeder 3 , the bottom of the pre-pyrolyzer 4 is provided with a lower closing air device 6 , and the outside of the pre-pyrolyzer 4 is provided with a pipe-type pre-pyrolyzer flue 5 . The upper part of the main pyrolyzer 22 is a fluidized bed reactor 7, and the outside of the fluidized ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com