Monitoring method of junction box for photovoltaic module

A photovoltaic module and junction box technology, applied in the field of photovoltaic systems, can solve problems such as single wiring conduction function, cumbersome work, and power generation decline of photovoltaic systems, and achieve the effects of reducing maintenance costs, ensuring economic benefits, and shortening maintenance time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

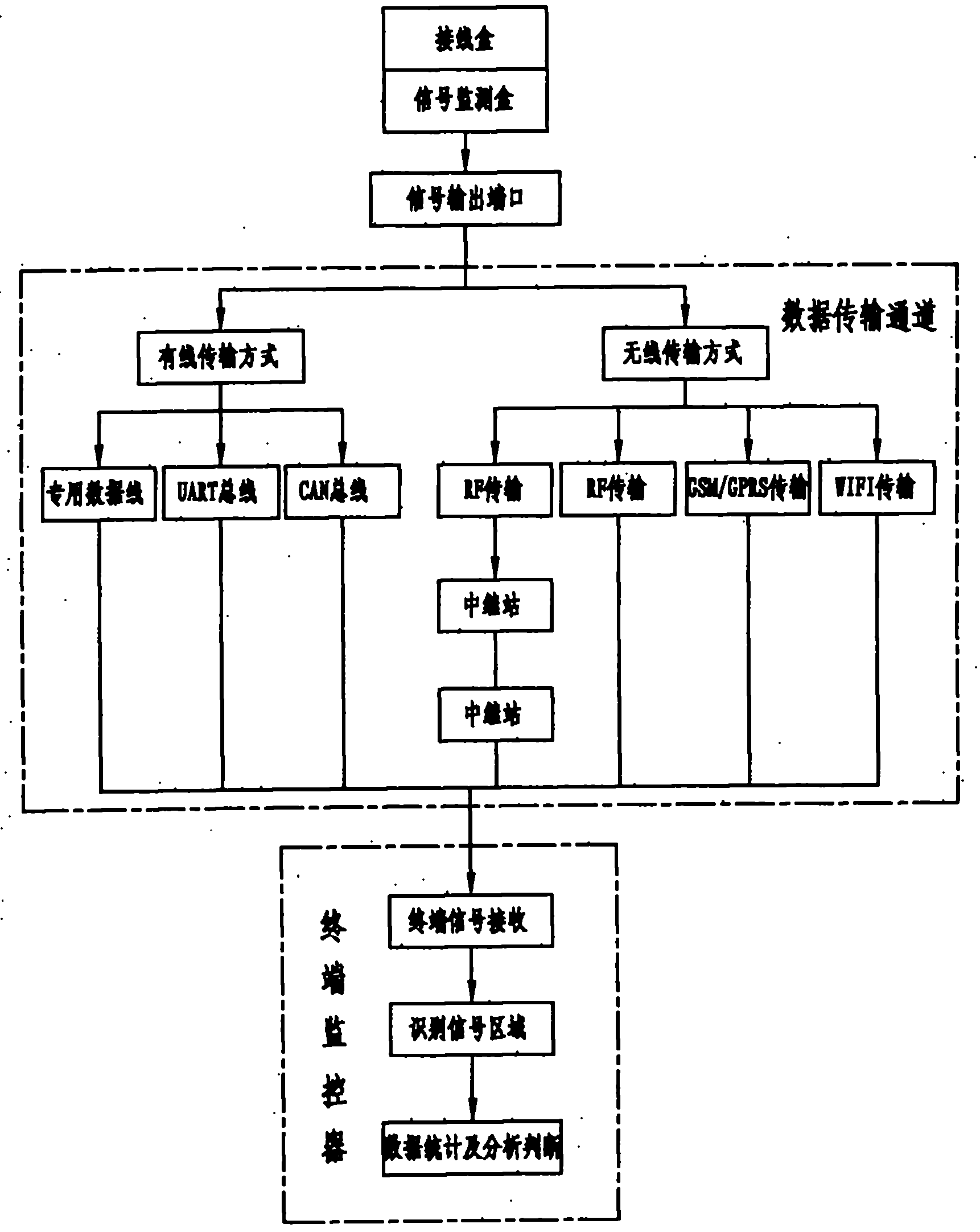

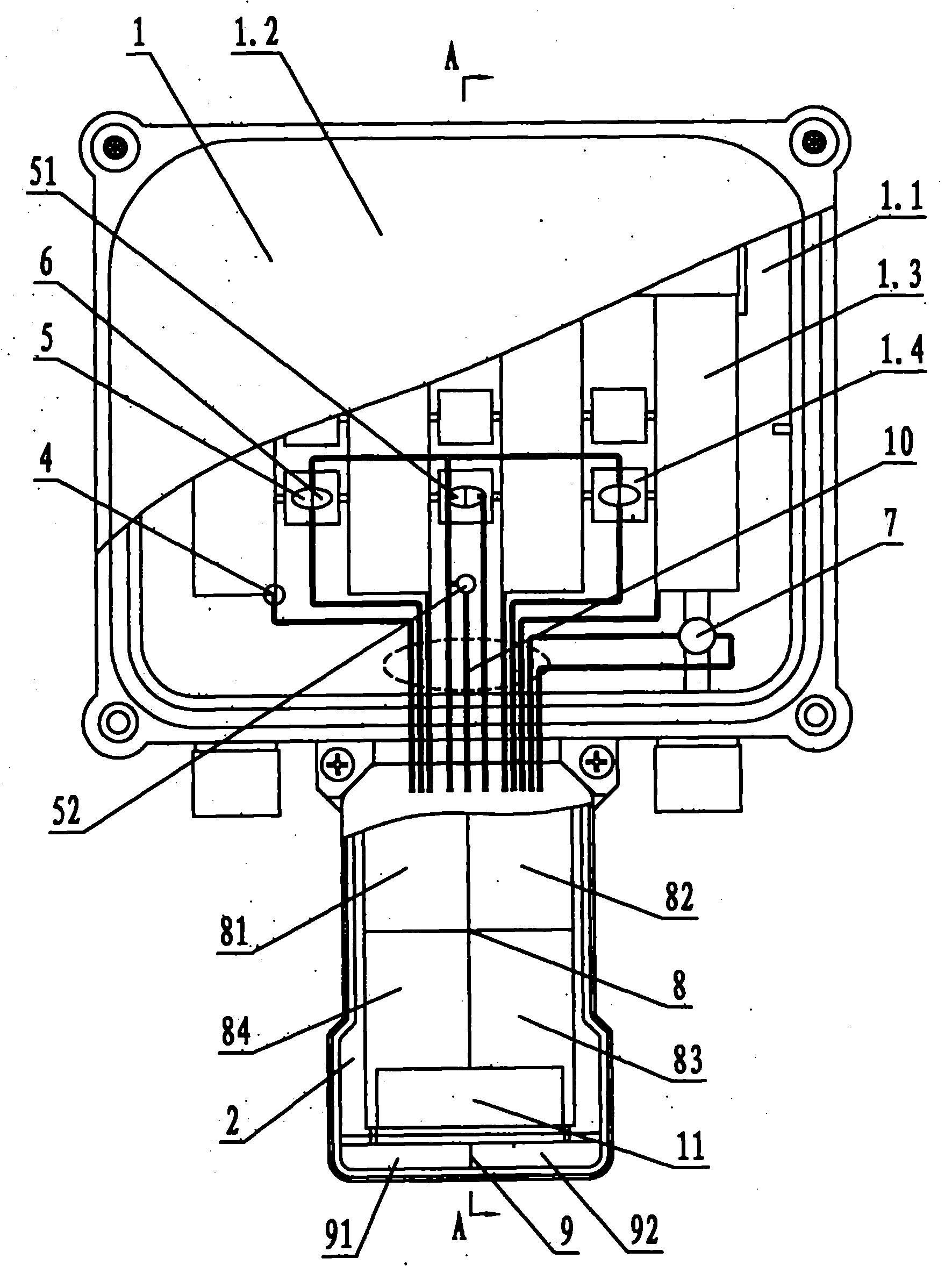

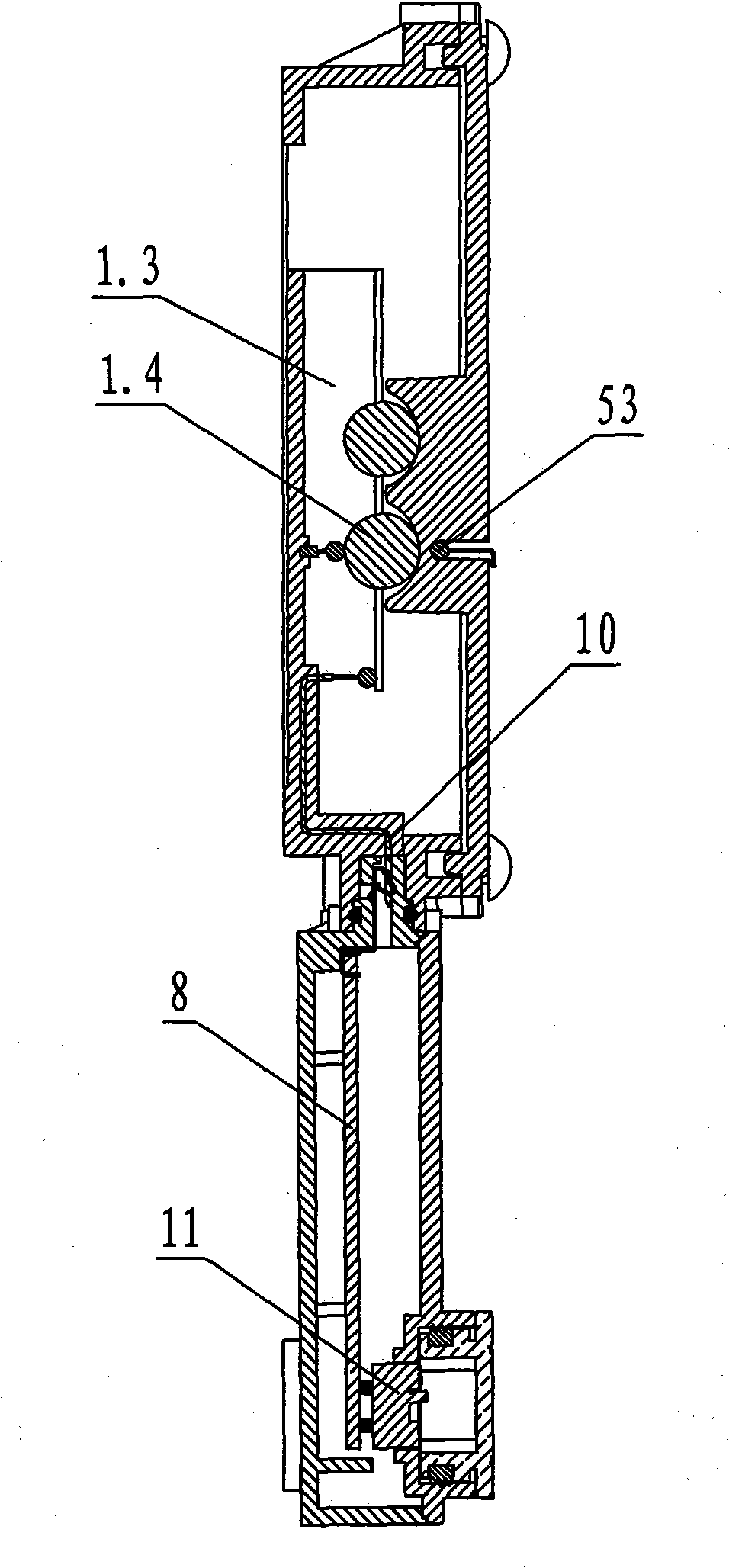

[0015] like figure 1 A working principle block diagram of a monitoring method for a junction box for a photovoltaic module shown, the monitoring method has the following steps: a, an electrical signal collection point is set inside the junction box 1, and voltage signals, current signals, and current signals in the junction box 1 are collected. The temperature signal and the magnetic flux signal pass the collected signal into the signal detection box 2 through the wire; b, the signal detection box 2 processes and calculates the received signal and outputs the obtained data through the signal output port 9; c, the data transmission channel transmits the signal The data output by the output port 9 is transmitted to the terminal monitor; d, the terminal monitor identifies the received data, and confirms the area corresponding to the photovoltaic cell assembly where the junction box 1 is located; e, the terminal monitor performs statistical analysis on the data, Judging the workin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com