Preparation method of hypericum perforatum extractive

A technology for extracting Hypericum perforatum, which is applied in the field of extracting active ingredients of plants, can solve the problems of long extraction time, high instrument cost, and low extraction efficiency, and achieve the effect of saving extraction time and space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

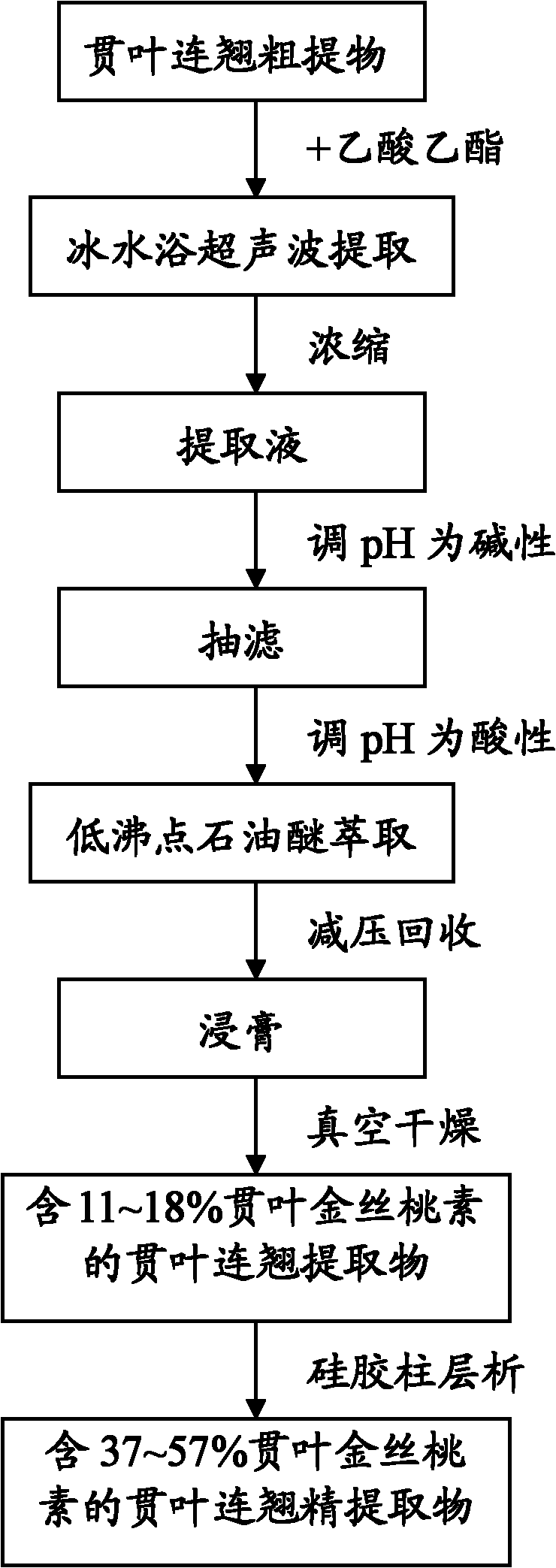

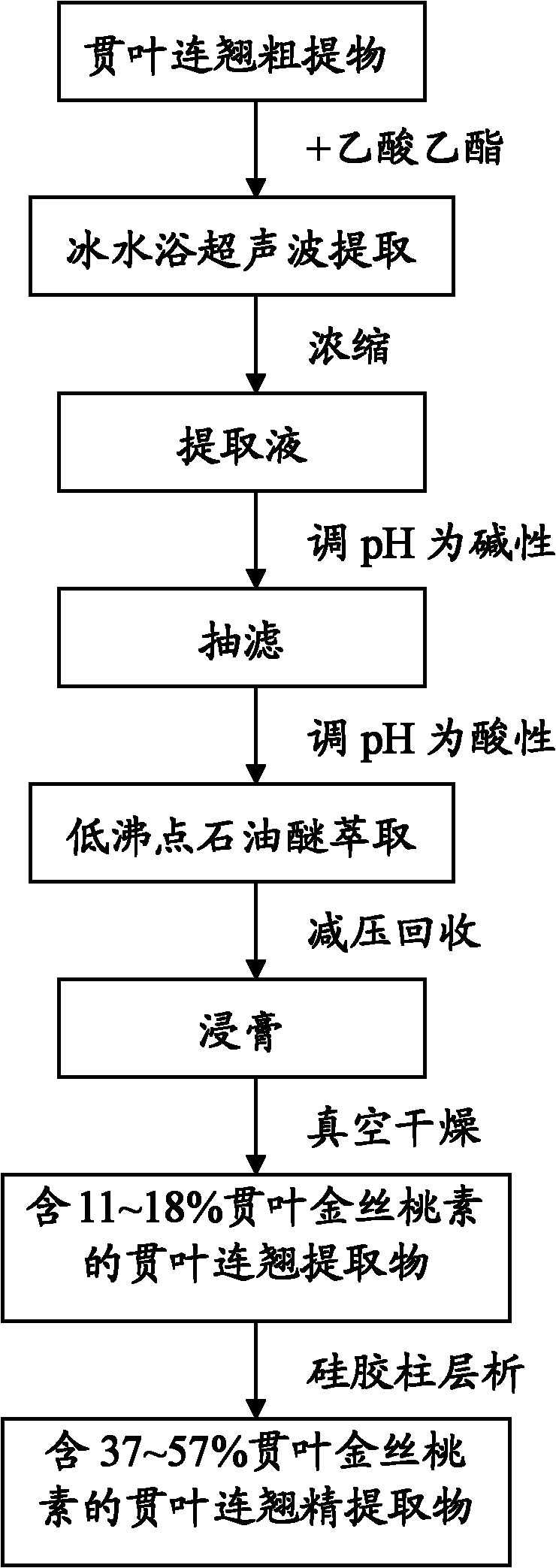

Method used

Image

Examples

Embodiment 1

[0020] Take 50 g of the crude extract of Hypericum perforatum, mix it with 250 ml of ethyl acetate, and conduct ultrasonic extraction in an ice-water bath for 60 min. Concentrate the extract obtained above into a concentrated solution containing 0.5-5 g / ml of the crude extract of Hypericum perforatum, adjust the pH to 8 with NaOH, filter with suction, take the filtrate, adjust the pH to 2 with 20% HCl, and use 150 ml of low-boiling petroleum ether Extract 3 to 5 times, combine petroleum ether phases, recover under reduced pressure to obtain extract, and vacuum dry at 0 to 20°C for 2 hours. The above extract was dissolved in a small amount of eluent and subjected to silica gel column chromatography. The eluent was petroleum ether: ethyl acetate: acetic acid = 80:19:1, appropriate amount of pressure was applied, and the collected solution was concentrated to obtain hyperforin-rich Hypericum perforatum extract, detected by HPLC, wherein the content of hypericin is 57%.

Embodiment 2

[0022] Take 50 g of the crude extract of Hypericum perforatum, mix it with 250 ml of ethyl acetate, and perform ultrasonic extraction in an ice-water bath for 30 min. Concentrate the extract obtained above into a concentrated solution containing 0.5-5 g / ml of Hypericum perforatum crude extract, adjust the pH to 8 with NaOH, take the filtrate after low-temperature high-speed centrifugation, adjust the pH to 2 with 20% HCl, and use 150 ml of low-boiling point petroleum Extract with ether for 3-5 times, combine petroleum ether phases, recover under reduced pressure to obtain extract, and dry in vacuum at 0-20°C for 2 hours. Dissolve the above extract in a small amount of eluent and carry out silica gel column chromatography. The eluent is petroleum ether: ethyl acetate = 10:1, pressurize appropriately, and the collected solution is concentrated to obtain a fine extract rich in hyperforin , after detection, wherein the content of hyperforin is 37%.

Embodiment 3

[0024] Take 50 g of the crude extract of Hypericum perforatum and extract it with 250 ml of ethyl acetate for 24 hours. Concentrate the extract obtained above into a concentrated solution containing 0.5-5 g / ml of the crude extract of Hypericum perforatum, adjust the pH to 8 with NaOH, filter with suction, take the filtrate, adjust the pH to 2 with 20% HCl, and use 150 ml of low-boiling petroleum ether Extract 3 to 5 times, combine petroleum ether phases, recover under reduced pressure to obtain extract, and vacuum dry at 0 to 20°C for 2 hours. The above extract was dissolved in a small amount of eluent and subjected to silica gel column chromatography. The eluent was petroleum ether: ethyl acetate: acetic acid = 80:19:1, appropriate pressure was applied, and the collected solution was concentrated to obtain hyperforin-rich The refined extract has been tested, and the content of hyperforin is 36%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com