Polytetrafluoroethylene hollow fiber stretching device

A polytetrafluoroethylene, stretching device technology, applied in membrane technology, semi-permeable membrane separation, chemical instruments and methods, etc., can solve the problems of difficult to effectively control the core rod, hollow fiber collapse, hollow fiber rupture, etc. Realize the effect of aperture control, energy saving and space saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

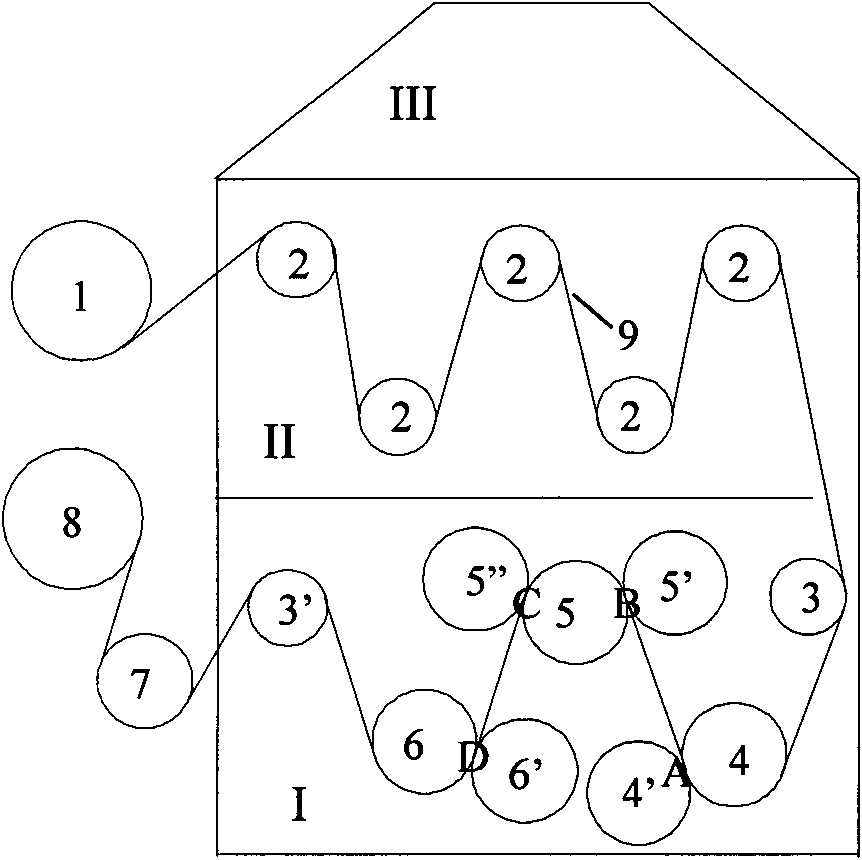

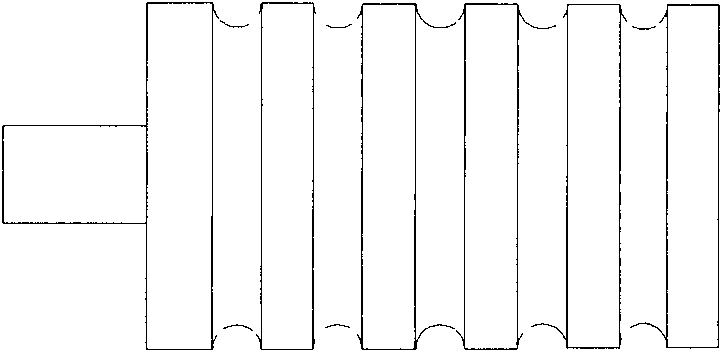

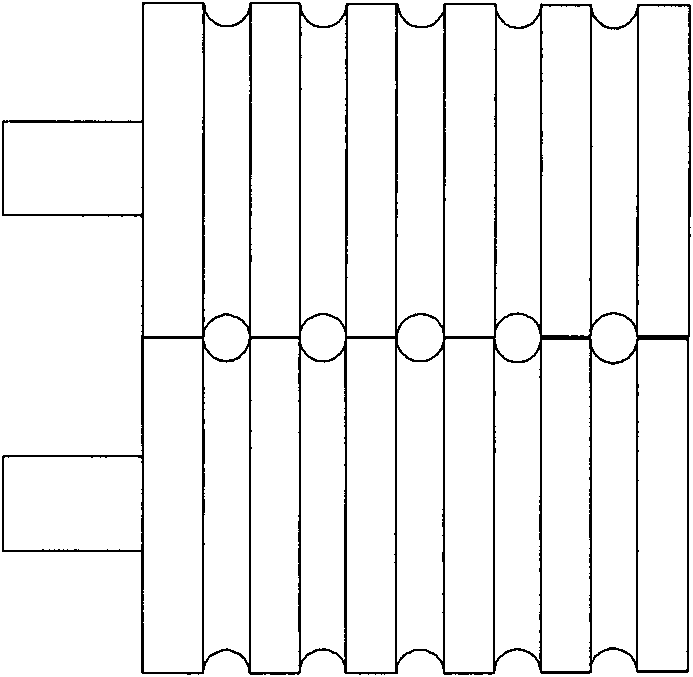

[0032]The paste is extruded and suspended to polymerize polytetrafluoroethylene resin to obtain a hollow fiber with an inner diameter of 2 mm and an outer diameter of 4 mm. Aviation kerosene is used as a lubricant with a lubricant content of 18 wt%. The unwinding roller 1 adopts a paper tube with a diameter of 40cm, and the degreasing roller 2 adopts a nickel-plated 45# steel with a diameter of 30cm, a hollow roller, a roller wall thickness of 8mm, and a roller length of 5cm. The number of slots is 4. 4 degreasing rollers are used, the effective degreasing length is 1.5m, and the surface speed of the degreasing roller is 5.0m / min. The degreasing oven temperature is 200°C. The guide roller 3 adopts the same specifications as the degreasing roller. Stretching rollers 4, 4', 5, 5', 5", 6, 6' all adopt nickel-plated 45# steel hollow rollers with a diameter of 30cm, the wall thickness of the rollers is 15mm, and the length of the rollers is 5cm. The stretching rollers 4, 4' surf...

Embodiment 2

[0034] The paste is extruded and suspended to polymerize polytetrafluoroethylene resin to obtain a hollow fiber with an inner diameter of 1 mm and an outer diameter of 2 mm. Aviation kerosene is used as a lubricant with a lubricant content of 20 wt%. The unwinding roller adopts a paper tube with a diameter of 10cm, and the degreasing roller adopts a nickel-plated 45# steel with a diameter of 20cm, a hollow roller, a roller wall thickness of 5mm, and a roller length of 6cm. for 10. Use 5 degreasing rollers, the effective degreasing length is 2m, and the surface speed of the degreasing roller is 1.0m / min. The degreasing oven temperature is 120°C. The guide roller 3 adopts the same specifications as the degreasing roller. Stretching rollers 4, 4', 5, 5', 5", 6, 6' are all made of stainless steel hollow rollers with a diameter of 15cm, the wall thickness of the rollers is 5mm, the length of the rollers is 6cm, and the surface of the stretching rollers 4 and 4' is open. The diam...

Embodiment 3

[0036] The paste is extruded and suspended to polymerize polytetrafluoroethylene resin to obtain a hollow fiber with an inner diameter of 0.5 mm and an outer diameter of 1 mm. Aviation kerosene is used as a lubricant, and the lubricant content is 20 wt%. The unwinding roller adopts a paper tube with a diameter of 10cm, and the degreasing roller adopts a nickel-plated 45# steel hollow roller with a diameter of 5cm. The wall thickness of the roller is 3mm, and the length of the roller is 8cm. 20. Three degreasing rollers are used, the effective degreasing length is 1m, and the surface speed of the degreasing roller is 10.0m / min. The degreasing oven temperature is 250°C. The guide roll and cooling roll adopt the same specifications as the degreasing roll. Stretching rolls 4, 4', 5, 5', 5", 6, 6' are all made of stainless steel solid rolls with a diameter of 5cm, and the length of the rolls is 8cm. The diameter of the semicircular grooves on the surface of rolls 5, 5', 5" is 0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com