Method for preparing lactobacillus acidophilus powder by freeze-drying in vacuum

A technology of vacuum freeze-drying and Lactobacillus acidophilus is applied in the field of preparing Lactobacillus acidophilus powder by vacuum freeze-drying, which can solve problems such as cell inactivation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Culture Lactobacillus acidophilus in MRS medium for 24h, then centrifuge at 6000r / min for 10min at a rotating speed, collect the thalline, then wash the thalline twice with normal saline, centrifuge and discard the supernatant; The cells were prepared to be 8±1×10 10 After cfu / mL bacterial suspension, let it stand for 30-40min, then add protective agent II and mix evenly, wherein, the volume ratio of the protective agent II and protective agent I is 1:1, then, let it stand for 20-30min before loading In a freeze-drying tube, the height of the sample is 0.3-0.5cm, and then placed in a refrigerator at -35 ~ -40°C for 24 hours, then transferred to a vacuum freeze dryer, at a temperature of -56°C and a vacuum of Freeze-dried for 24 hours under the condition of 4-6Pa; finally, reconstituted with normal saline, counted on MRS solid medium, and determined the activity of bacteria powder and the survival rate of bacteria.

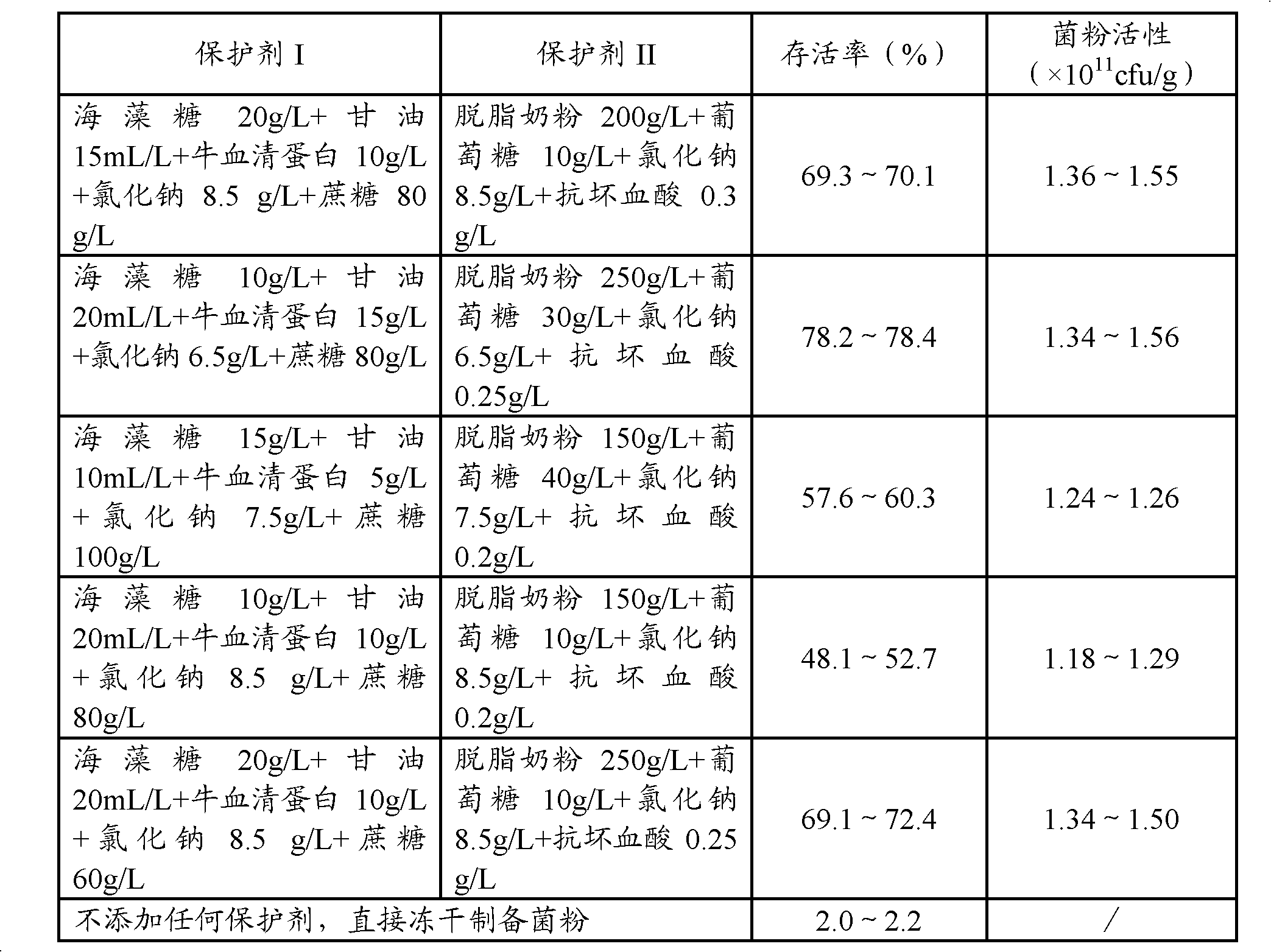

[0018] The formula of above-mentioned protective agen...

Embodiment 2

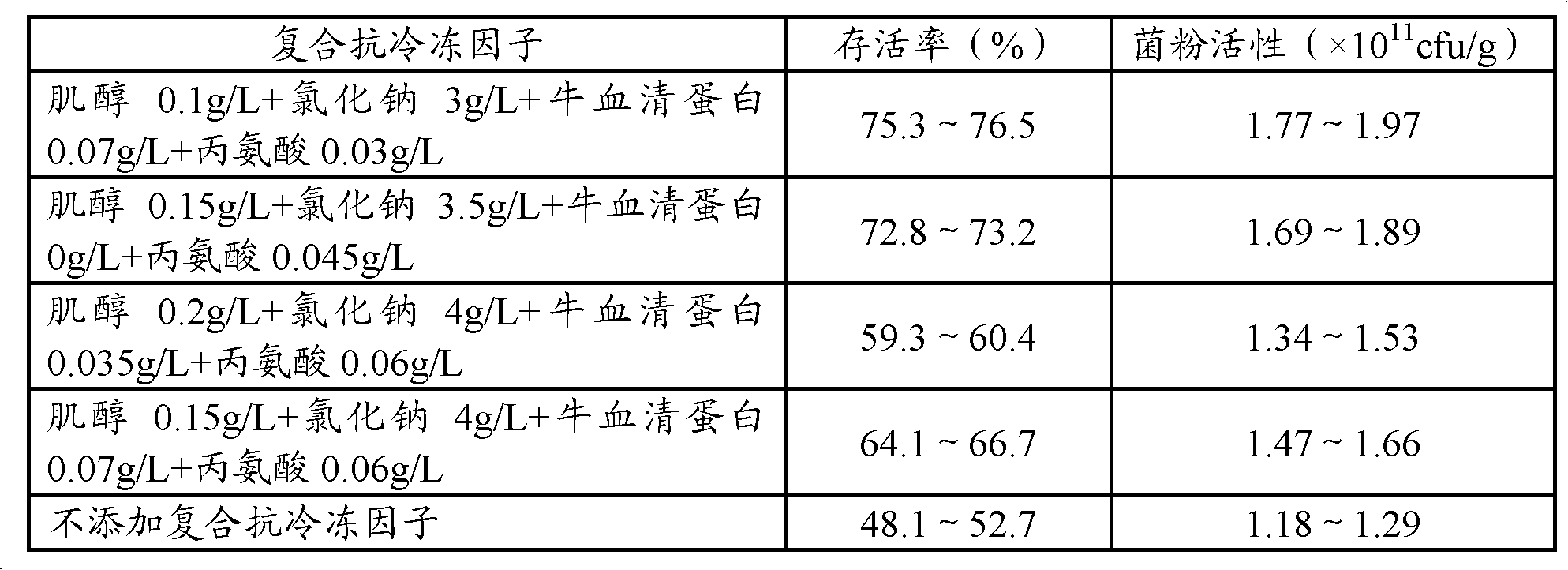

[0022] Embodiment 2 is identical with embodiment 1 step, just, in aseptic MRS substratum, at first add the compound antifreeze factor of microporous membrane sterilization, then cultivate Lactobacillus acidophilus, wherein, the prescription of the protective agent I of adding It is: trehalose 10g / L+glycerin 20mL / L+bovine serum albumin 10g / L+sodium chloride 8.5g / L+sucrose 80g / L; the formula of the added protective agent II is: skim milk powder 150g / L+glucose 10g / L+sodium chloride 8.5g / L+ ascorbic acid 0.2g / L, the formula of described compound antifreeze factor is as shown in table 2 below:

[0023] Table 2 The verification results of the lyophilized survival rate of the bacteria obtained by adding different ratios of compound antifreeze factors fermented

[0024]

Embodiment 3

[0026] The method for preparing Lactobacillus acidophilus by vacuum freeze-drying in Example 3 is exactly the same as in Example 2, wherein, the formula of the compound antifreeze factor adopts: inositol 0.1g / L, sodium chloride 3g / L, bovine serum albumin 0.07g / L, alanine 0.03g / L; the formula of protective agent I adopts: trehalose 10g / L+glycerol 20mL / L+bovine serum albumin 10g / L+sodium chloride 8.5g / L+sucrose 80g / L; the formula of protective agent II Use: skimmed milk powder 150g / L+glucose 10g / L+sodium chloride 8.5g / L+ascorbic acid 0.2g / L, the volume ratio of the protective agent I and protective agent II is shown in the following table 3:

[0027] Table 3 The verification results of the survival rate of Lactobacillus acidophilus bacterial powder prepared by freeze-drying of the different volume ratios of the protective agent I and the protective agent II of the bacterial suspension

[0028] Protective agent I made into bacterial suspension: Protective agent II

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com