Flue gas-heat recovery cooling and heating system

A technology for cooling, heating, and heating systems, which is used in heating and cooling combinations, refrigerators, refrigeration components, etc., can solve the problems of uneconomical, high operating costs, and high boiler exhaust gas temperature, and achieve good economic and social benefits. , the effect of reducing electricity or fuel consumption, reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

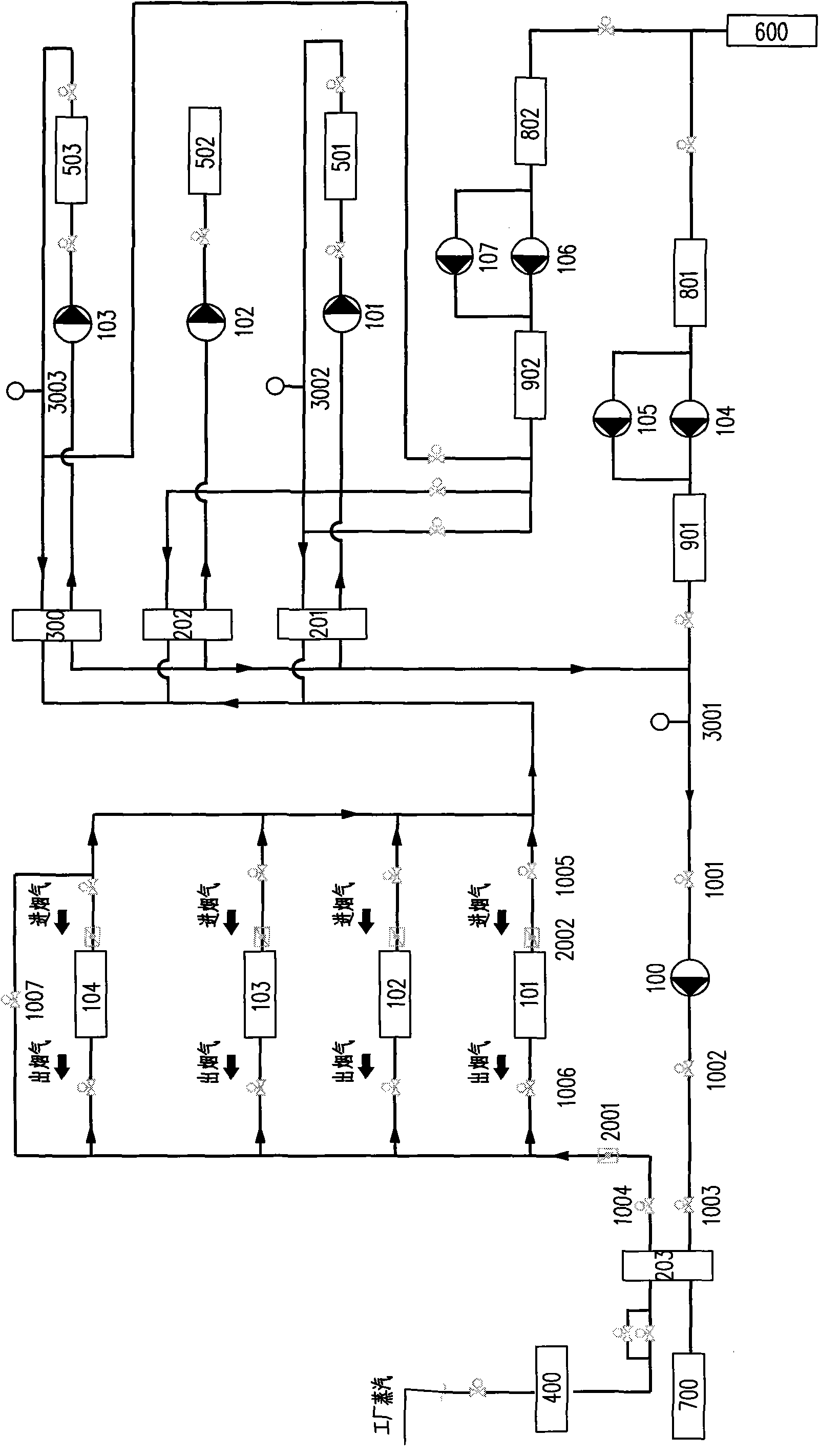

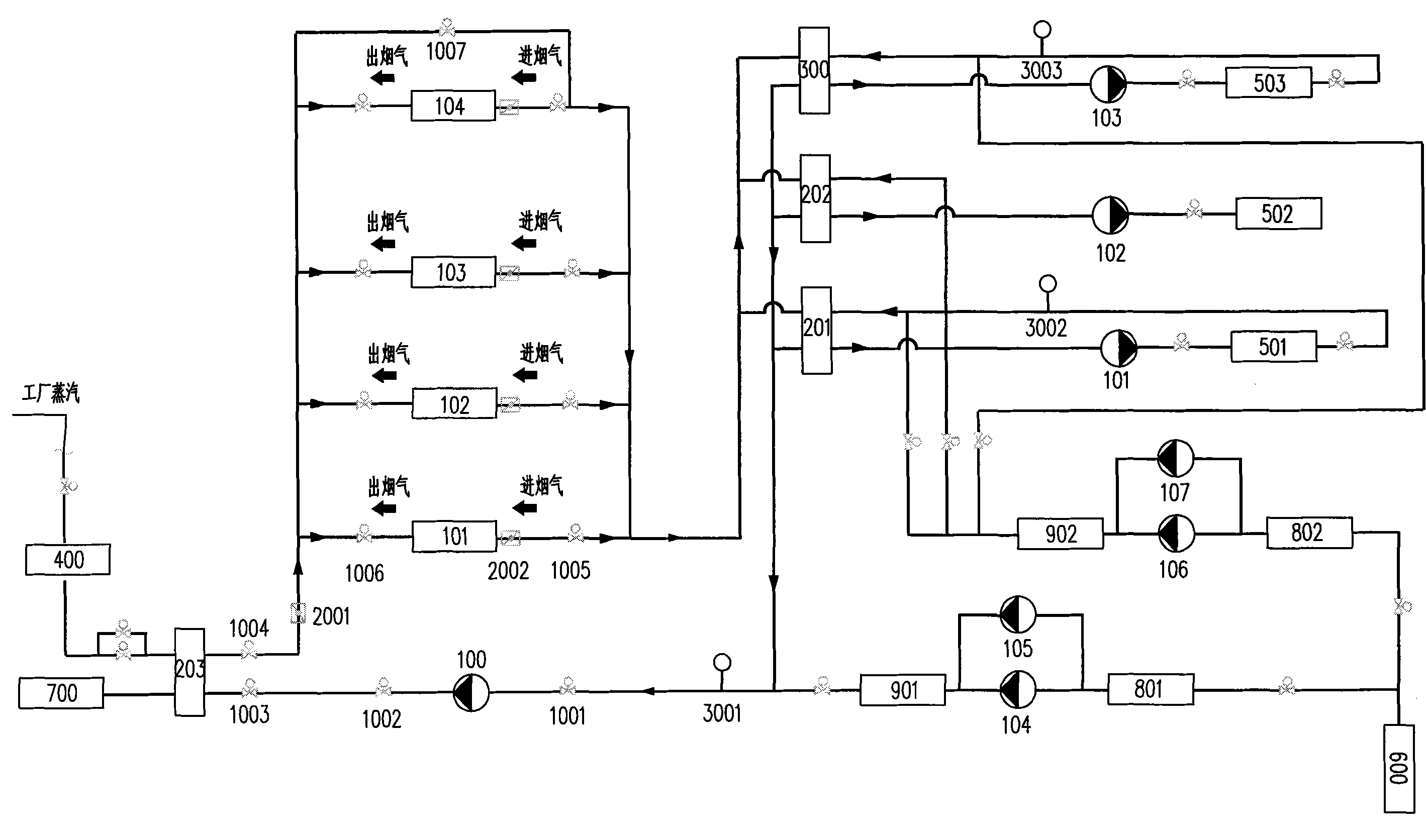

[0045] As shown in Figure 1, the flue gas-heat recovery refrigeration and heating system according to the present invention includes a hot water pump 100, a first flue gas-heat recovery device 101, a first plate heat exchanger 201, a No. 1 pump 101, a No. Second plate heat exchanger 201, No. 2 pump 102, lithium bromide refrigerator 300, No. 3 pump 103, third plate heat exchanger 203, factory steam temperature reduction and decompression device 400, water supply device, domestic hot water user terminal 502, air conditioner The hot water user terminal 501, the air conditioner chilled water user terminal 503 and the system control circuit, the input end of the hot water pump 100 is respectively connected to the first plate heat exchanger 201, the second plate heat exchanger 202 and the first exchange of the lithium bromide refrigerator 300 The output end of the flow channel is connected, the input end of the second exchange flow channel of the third plate heat exchanger 203 is con...

Embodiment 2

[0057] This embodiment is similar to Embodiment 1, except that the system is used to prepare hot water for air-conditioning and domestic hot water, and does not prepare chilled water for air-conditioning, that is, the system does not include the refrigerator 300, the user terminal 503 for chilled water for air-conditioning and the corresponding pipelines, valves, pumps, water supply lines.

Embodiment 3

[0059] This embodiment is similar to Embodiment 1, except that the system is only used to prepare chilled water for air-conditioning, and the system does not include the first and second plate heat exchangers, air-conditioning hot water user terminals 501, air-conditioning refrigeration Water user terminal 503 and corresponding pipelines, valves, pumps, and water replenishment pipelines.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com