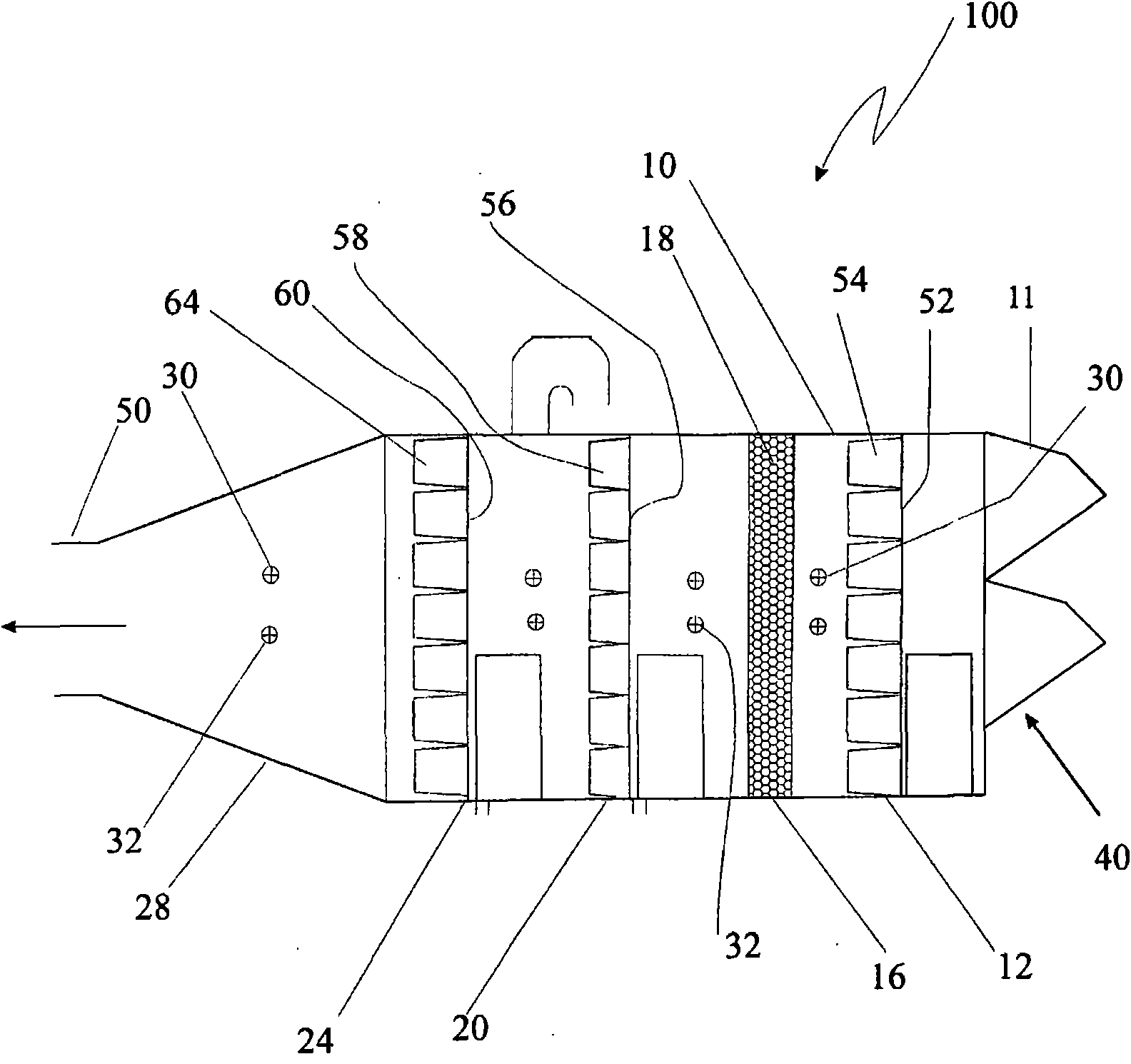

A system for inlet air mass enhancement

A technology of air intake and air, which is applied in jet propulsion devices, gas turbine devices, dispersed particle filtration, etc., can solve the problems that cannot meet the needs of air volume, and achieve the effect of low installation cost and constant temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

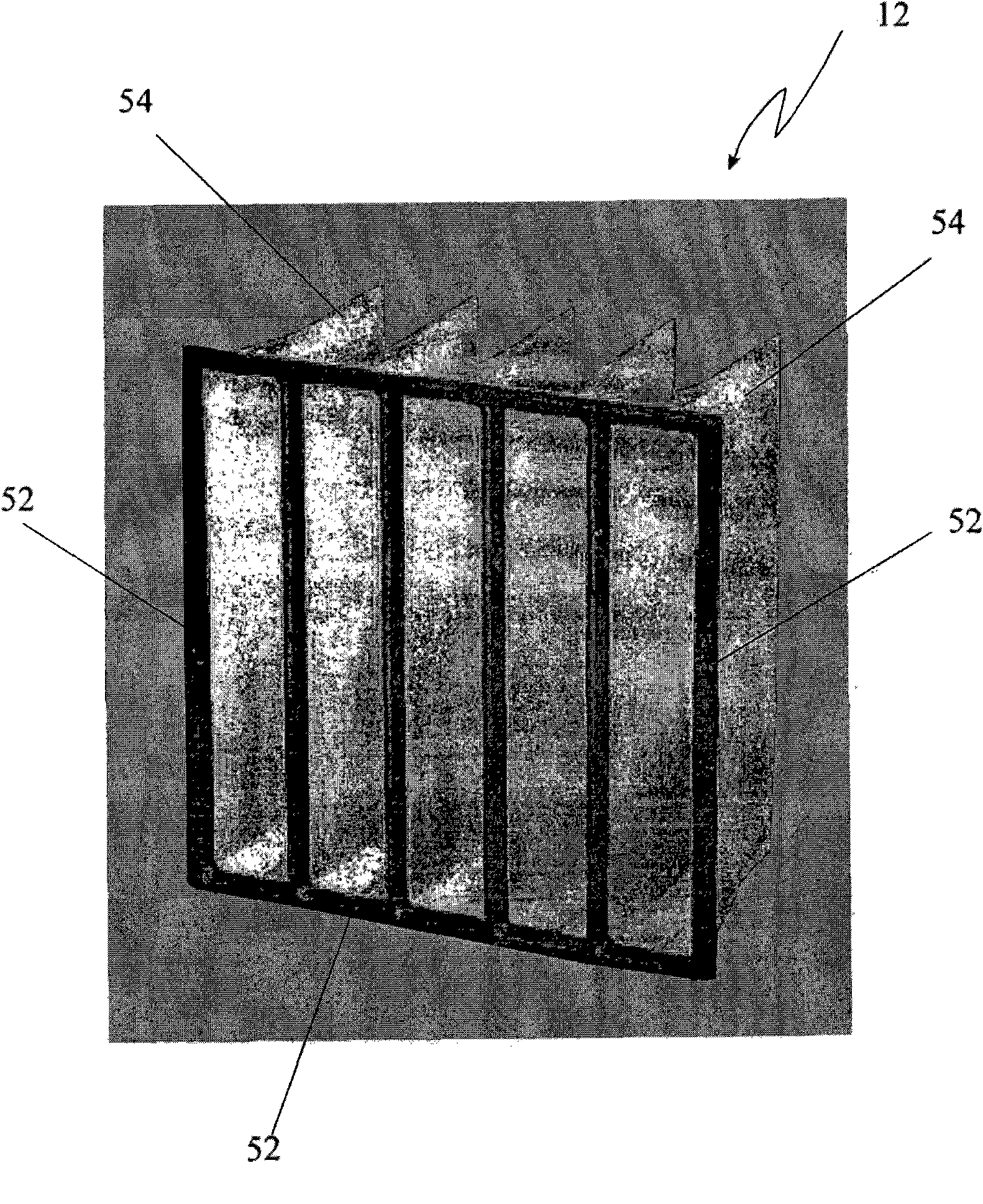

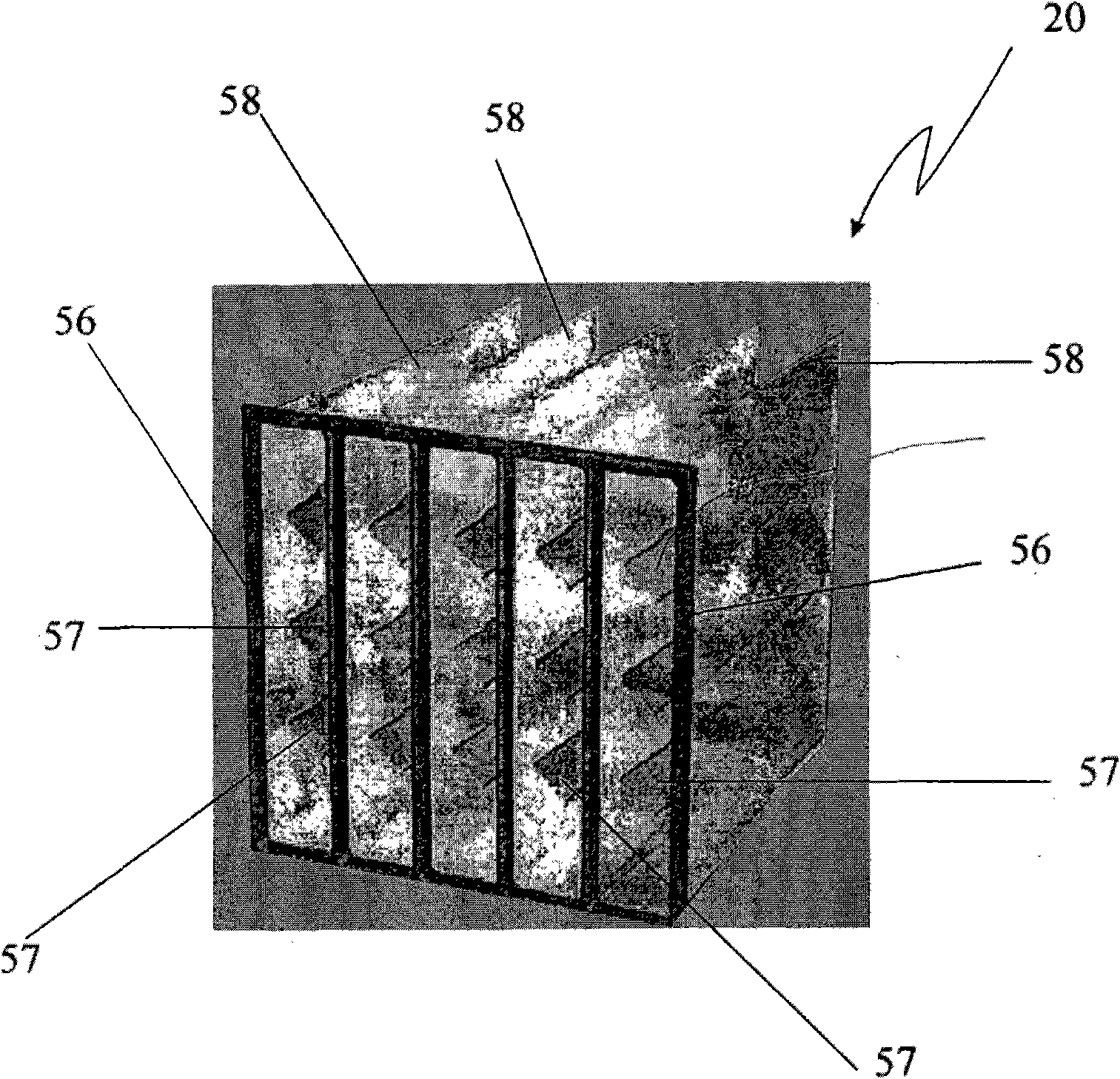

Method used

Image

Examples

example 1

[0129] Example 1 (multi-filter media system with cooling according to the invention at a temperature of 28-30° C.)

[0130] Assemble progressive filter media in a test stand with a primary, intermediate and fine filtration station. The test bench is provided between the first filter unit and the second filter unit with a set of filters made according to the invention with a surface area of 16m 2 cooling coil. The refrigeration unit was turned on and the temperature in the cooling zone was maintained at 28-30°C. Unfiltered atmosphere is drawn by a centrifugal blower and into the inlet port of the filter bank. The pressure and temperature at the inlet and outlet sides of each filter were recorded continuously. The cooling rate was adjusted to maintain a steady temperature of 28-30°C in the cooling zone throughout the test. Calculate and record the flow rate through the filter. A typical flow rate achieved is 68,000 Cu.m / hr with a pressure drop of 40-50 Pa.

example 2

[0131] Example 2 (multi-filter media system with cooling)

[0132] Repeat the above test after replacing all filter media with the same grade of media, but maintain the cooling zone at 15°C. The cooling rate was adjusted throughout the test to maintain a steady temperature of 15°C in the cooling zone. Calculate and record the flow rate through the filter. A typical flow rate achieved is 72,000 Cu.m / hr with a pressure drop of 40-50 Pa.

[0133] The above tests confirmed that the mass flow rate was increased without significantly increasing the pressure drop across the system.

[0134] The air output achieved according to the present invention is generally clean, particle size no larger than desired micron size at temperatures of 4-30°C, with low ΔP (pressure loss) and increased air volume entering the process unit or equipment.

[0135] Thus, the amount of air was increased without significantly affecting other air parameters.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com