Panaxtriol saponin extract and preparation process thereof

A technology of notoginseng triol group and notoginseng saponin, which is applied in the field of extract notoginseng triol saponin extract of traditional Chinese medicine Panax notoginseng and its preparation field, which can solve the problems of high content of notoginseng triol, notoginseng triol and notoginseng two Eliminate problems such as poor alcohol effect, achieve the effect of high content, good separation effect, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

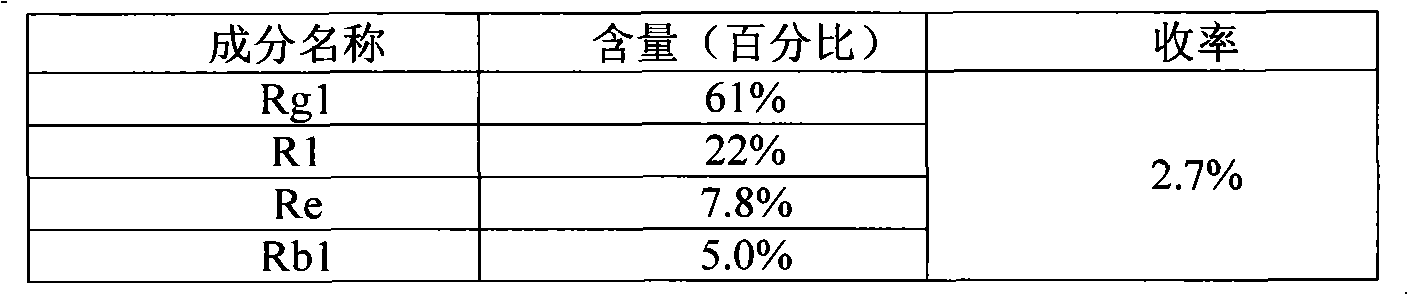

Embodiment 1

[0046] Take 20.0g of Panax notoginseng, crush it into coarse particles, add 3 times the amount of 70% ethanol to soak for 8 hours, put it into a percolation barrel for percolation, collect 30 times the percolation liquid, and the percolation flow rate is 1BV / h; Concentrate under reduced pressure at ℃ to 1.5 times of medicinal material, centrifuge at 4200rpm for 20min, put D101 macroporous adsorption resin on the supernatant, the weight ratio of resin to raw material drug is 1:1, the sample loading flow rate is 0.5BV / h, wash with 4 times column volume , the washing flow rate was 1BV / h, and the washing solution was discarded, and eluted with 8 times column volume of 30% ethanol, and the elution flow rate was 1.5BV / h, and the eluent was collected. Recover the eluate until it has no alcohol smell, put it on D941 resin, the weight ratio of resin to medicinal material is 0.8:1, the flow rate of sample loading is 1BV / h, the column volume is 10 times, the flow rate is 1.5BV / h, wash wit...

Embodiment 2

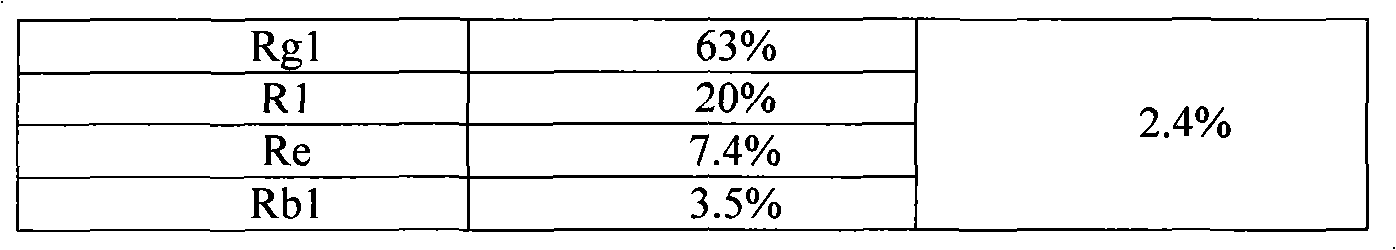

[0050] Take Panax notoginseng 20.0, crush it into coarse particles, add 4 times the amount of 70% ethanol to soak for 6 hours, put it into a percolation barrel for percolation, collect 20 times the percolation liquid, and the percolation flow rate is 1BV / h; Concentrate under reduced pressure to 1.2 times of medicinal materials, centrifuge at 4000rpm for 20min, put D101 macroporous adsorption resin on the supernatant, the weight ratio of resin to raw material drug is 1:1, the sample loading flow rate is 0.5BV / h, wash with 4 times column volume, The washing flow rate was 1 BV / h, the washing solution was discarded, and 20 times the column volume was eluted with 30% ethanol, and the elution flow rate was 1.5 BV / h, and the eluent was collected. Recover the eluate until it has no alcohol smell, apply D941 resin, the weight ratio of resin to medicinal material is 0.5:1, the flow rate of the sample is 1BV / h, 5 times the column volume, the flow rate is 1.5BV / h, wash with water; collect ...

Embodiment 3

[0055] Take 100.0g of Panax notoginseng, crush it into coarse particles, add 8 times the amount of 70% ethanol to soak for 10 hours, put it into a percolation barrel for percolation, collect 20 times the percolation liquid, and the percolation flow rate is 1BV / h; Concentrate under reduced pressure at ℃ to 1.6 times of medicinal material, centrifuge at 6000rpm for 20min, put D101 macroporous adsorption resin on the supernatant, the weight ratio of resin to raw material drug is 1:1, the sample loading flow rate is 0.5BV / h, wash with 4 times column volume , the washing flow rate is 1BV / h, the washing solution is discarded, and eluted with 10 times column volume of 30% ethanol, the elution flow rate is 1.5BV / h, and the eluent is collected. Recover the eluate until it has no alcohol smell, put it on D941 resin, the weight ratio of resin to medicinal material is 1:1, the flow rate of sample loading is 1BV / h, 8 times the column volume, the flow rate is 1.5BV / h, wash with water; collec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com