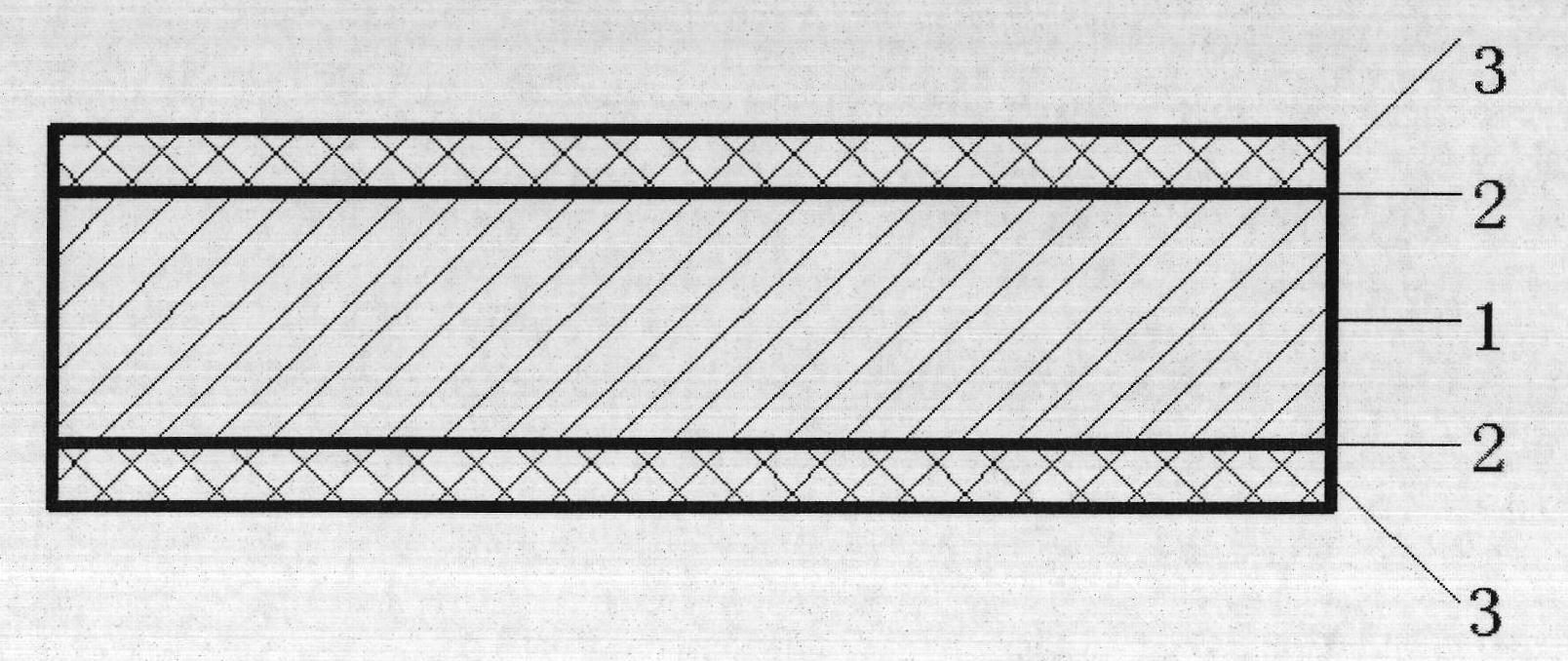

Water swelling rubber, metallic composite sealing material and preparation methods thereof

A composite technology of water-absorbing rubber and metal, which is applied in the direction of metal layered products, engine seals, chemical instruments and methods, etc., can solve problems such as difficulty in guaranteeing bonding strength, inability to withstand high pressure and high temperature, etc. Strength problems, high pressure, reducing the effect of rubber elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

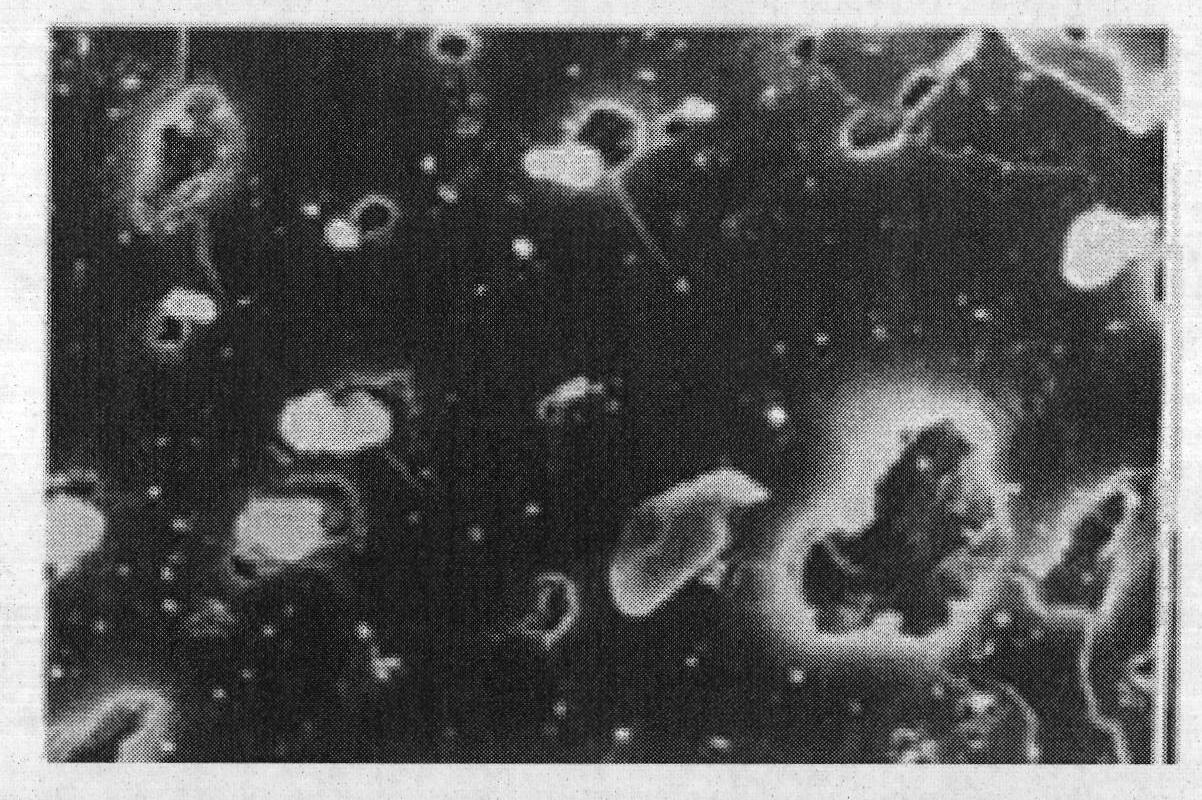

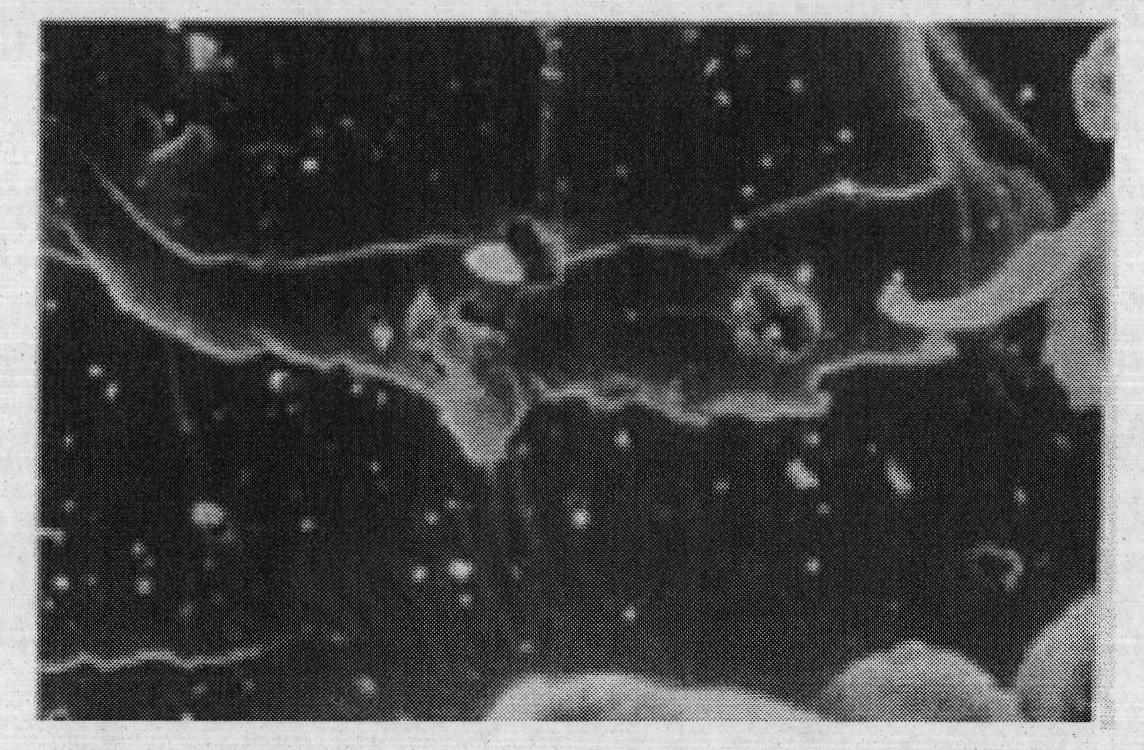

[0041] The water-swellable rubber of this embodiment is prepared by blending two kinds of superabsorbent resins SAP1# and SAP2# with rubber by physical blending method, wherein SAP1# uses acrylic acid, acrylamide and sodium propylene sulfonate as monomers, and adopts It is a ternary copolymerized superabsorbent resin prepared by aqueous solution polymerization, and SAP2# is a binary copolymerized superabsorbent resin made of carboxymethylated cellulose grafted with acrylamide.

Embodiment 2

[0043] The difference from Example 1 is that the particle size of the superabsorbent resin used is less than 80 μm.

Embodiment 3

[0045] The difference from Example 2 is that this example uses SAP1# and SAP2# on the basis of using the third superabsorbent resin SAP3# mixed with rubber. SAP3# is made of starch, acrylic acid, Super absorbent resin obtained by grafting acrylamide and maleic anhydride.

[0046] The water-absorbing swellable rubber prepared by mixing SAP1#, SAP2#, SAP3# alone with rubber and the water-absorbed swellable rubber obtained in Examples 2 and 3 were proposed respectively, and the volume expansion ratios of primary water absorption and secondary water absorption were tested, and the experimental results obtained The situation is shown in the table below:

[0047] Table 1 Experimental data table of compounding agent

[0048]

[0049] experiment analysis:

[0050] From the data in the above table, it can be seen that when using multiple resins together, the volume expansion rate of primary water absorption and the volume expansion rate of secondary water absorption are better, es...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com