Method for improving uniformity in diffusion film resistance chip of solar cell

A technology of solar cells and thin film resistors, applied in circuits, electrical components, climate sustainability, etc., can solve the problems of furnace tube heat balance point difference, furnace wire failure, cumbersome replacement, etc., to achieve low cost maintenance and good uniformity , the effect of high conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

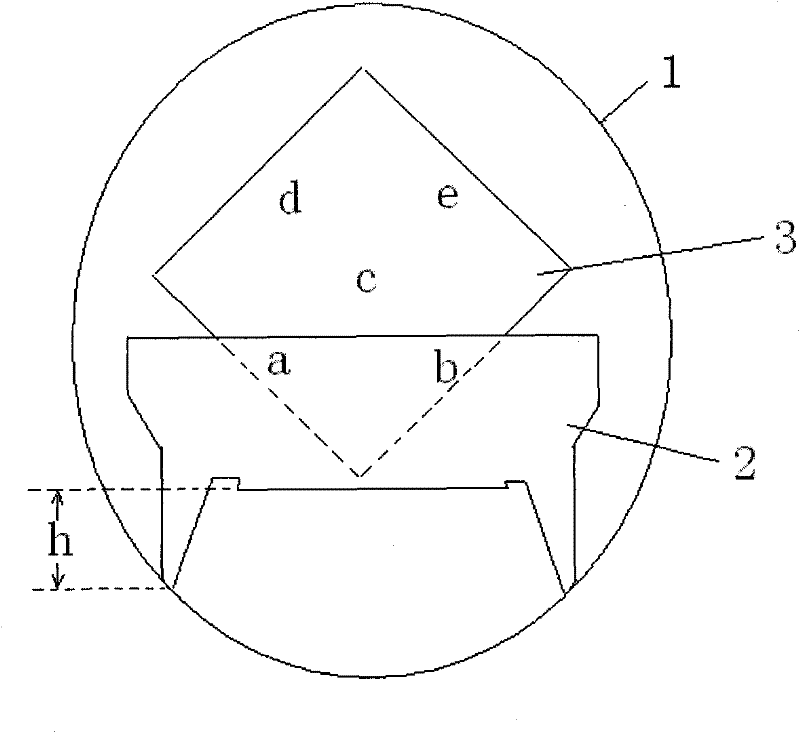

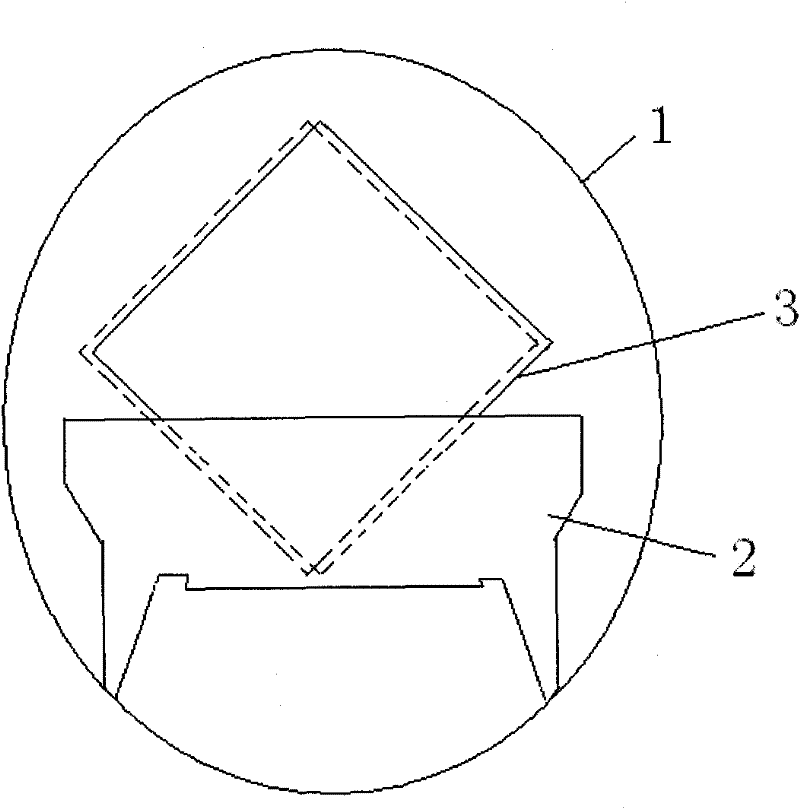

[0023] Such as figure 1 As shown, the solar cell has a silicon chip 3, and the silicon chip 3 is placed on the quartz boat 2 through a slot in the quartz boat 2, and the quartz boat 2 with the silicon chip 3 is placed in the diffusion furnace tube 1, and the diffusion furnace tube 1 is heated The silicon wafer 3 is diffused.

[0024] Embodiments of the invention:

[0025] A method for improving the uniformity of solar cell diffused thin film resistors:

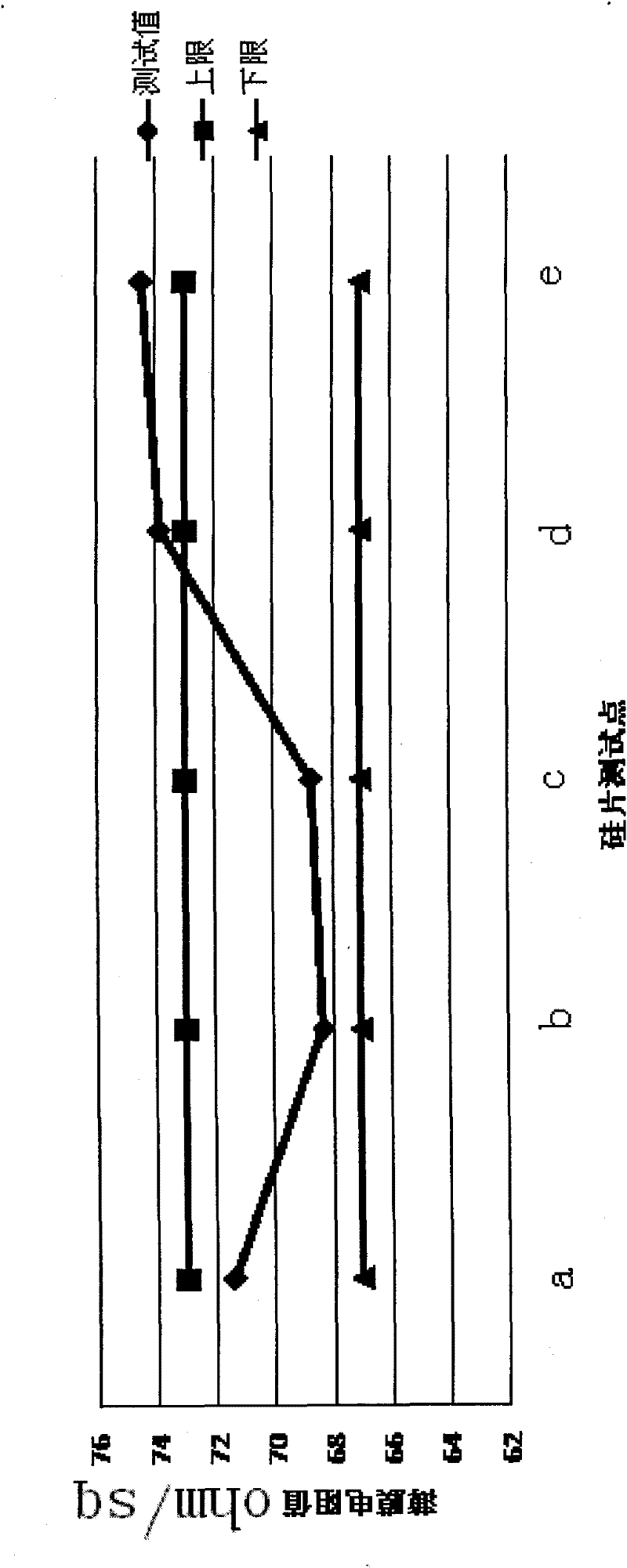

[0026] i. The silicon wafer 3 obtained after being diffused by the diffusion furnace tube 1 is subjected to the diffusion film resistance distribution test: the test point is set on the silicon wafer 3, the test point a is at the lower left of the silicon wafer 3, and the test point is at the lower right of the silicon wafer 3 b, the center of silicon wafer 3 is test point c, the upper left of silicon wafer 3 is test point d, and the upper right of silicon wafer 3 is test point e;

[0027] ii. According to the diffusion fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com