Mold release sheet and molded articles

A technology for mold release and sheet materials, which is applied to the field of mold release sheets and molded products using the mold release sheets, and can solve problems such as environmental deterioration, operability deterioration, and production decline.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

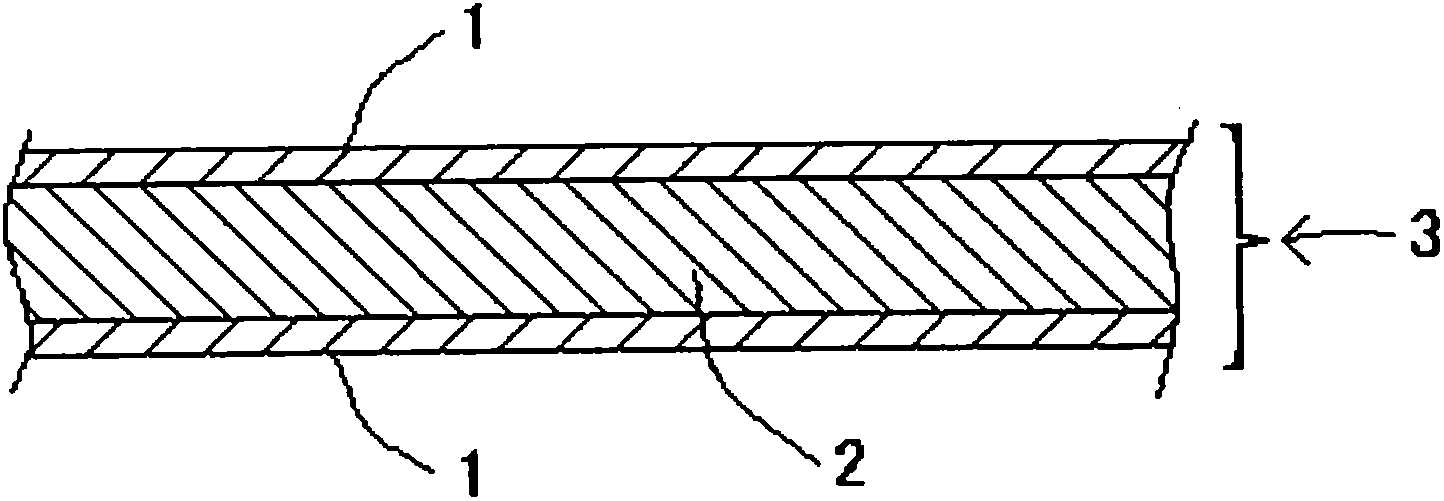

[0155] [Releasable sheet]

[0156] (1) Porous sheet (base sheet)

[0157] Use a fiber sheet made of polyester fiber and made by spunlacing (mass per unit area: 40g / m2) 2 , thickness: 0.4mm, ventilation resistance: 0.04kPa·s / m).

[0158] (2) Water-based adhesive

[0159] A mixed solution consisting of 30 parts by mass of Acrodur 958D (trade name, manufactured by BASF Japan Corporation, solid content: 42%) and 70 parts by mass of water was used.

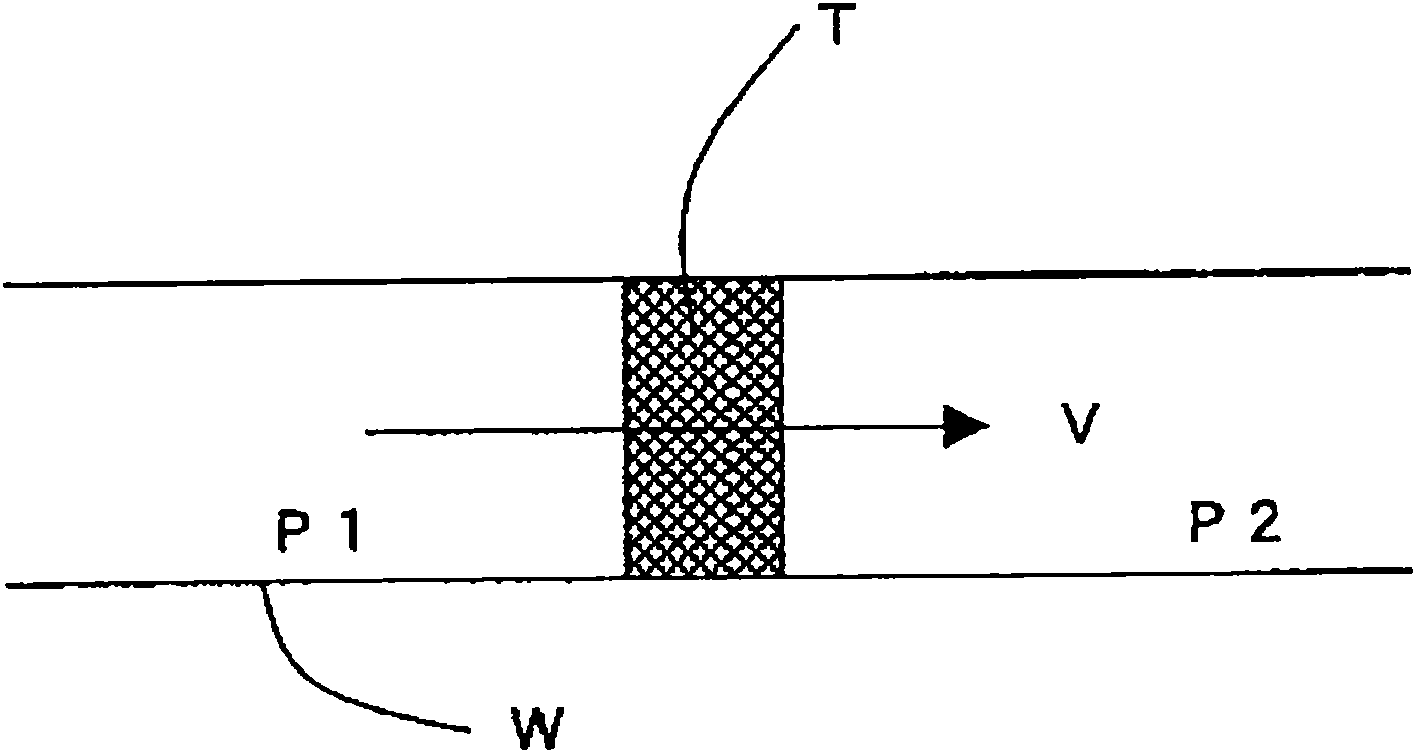

[0160] (3) Manufacture of release sheet

[0161] The release property was obtained by coating and impregnating the above-mentioned water-based adhesive on the above-mentioned porous sheet with a solid content of 5% by mass, and then drying it at 150°C for 4 minutes. Sheet.

[0162] [molding]

[0163] (1) Substrate

[0164] The mass per unit area of the novolac resin type phenolic resin powder using 20% by mass attached to the fiber weight is 800g / m 2 felt raw cotton sheet (thickness: 10mm).

[0165] (2) Manufacture of mold...

Embodiment 2

[0171] Except for changing the following matters in Example 1, it carried out in the same manner, and obtained the molding.

[0172] (1) Porous sheet (base sheet)

[0173] Using creped paper composed of 100% pulp (mass per unit area: 20g / m 2 , Shrinkage rate: 30%, thickness: 0.15mm, ventilation resistance: 0.10kPa·s / m).

[0174] The test results are shown in Table 1.

Embodiment 3

[0176] Except for changing the following matters in Example 1, it carried out in the same manner, and obtained the molding.

[0177] (1) Porous sheet (substrate sheet)

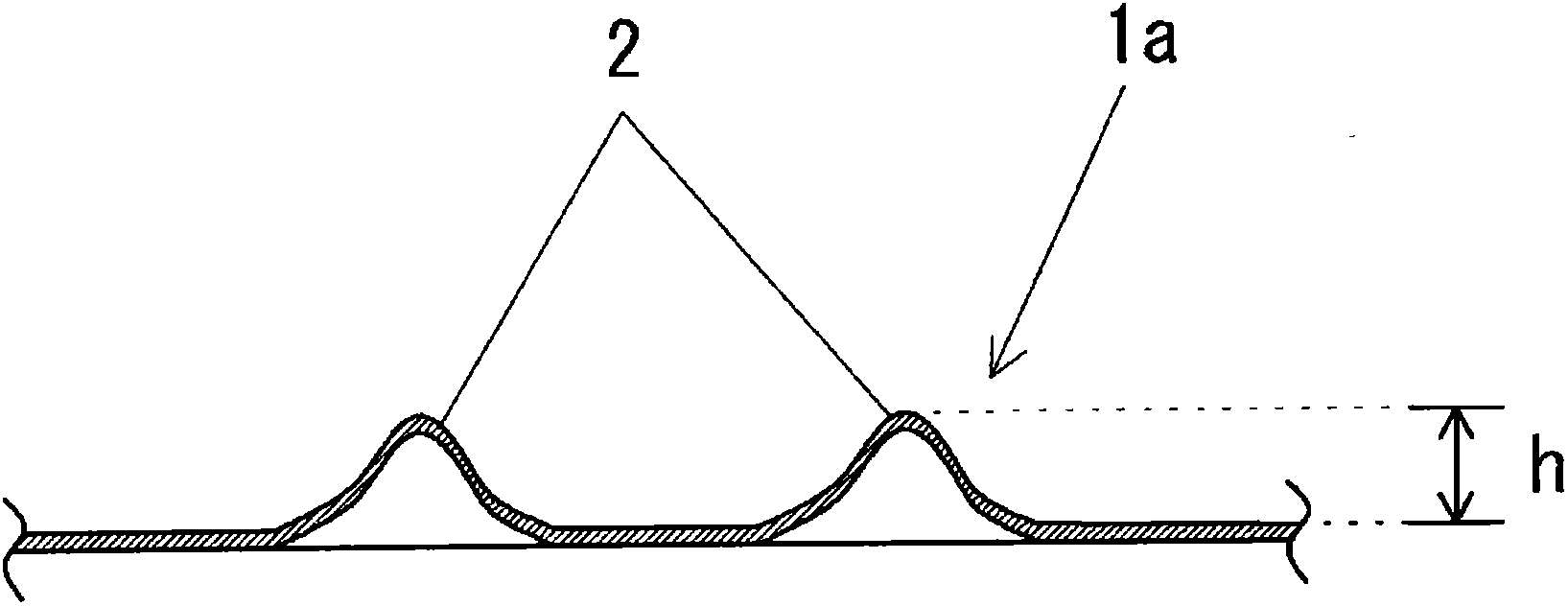

[0178] Using embossed paper composed of 100% pulp (mass per unit area: 20g / m 2 , Protrusion height: 0.2mm, Protrusion number: 120 / m 2 , Ventilation resistance: 0.10kPa·s / m).

[0179] The test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Ventilation resistance | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com