Self-locking acetabular posterior-wall posterior-column anatomical steel plate

A steel plate and acetabular technology, which is applied in the field of self-locking acetabular posterior wall and post anatomical steel plate, can solve the problems of soft tissue stripping, loss of joint function, weak immediate stability, etc., to achieve easy growth and crawling coverage, and prevent fracture blocks The effect of displacement and good internal fixation strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The first locked block a

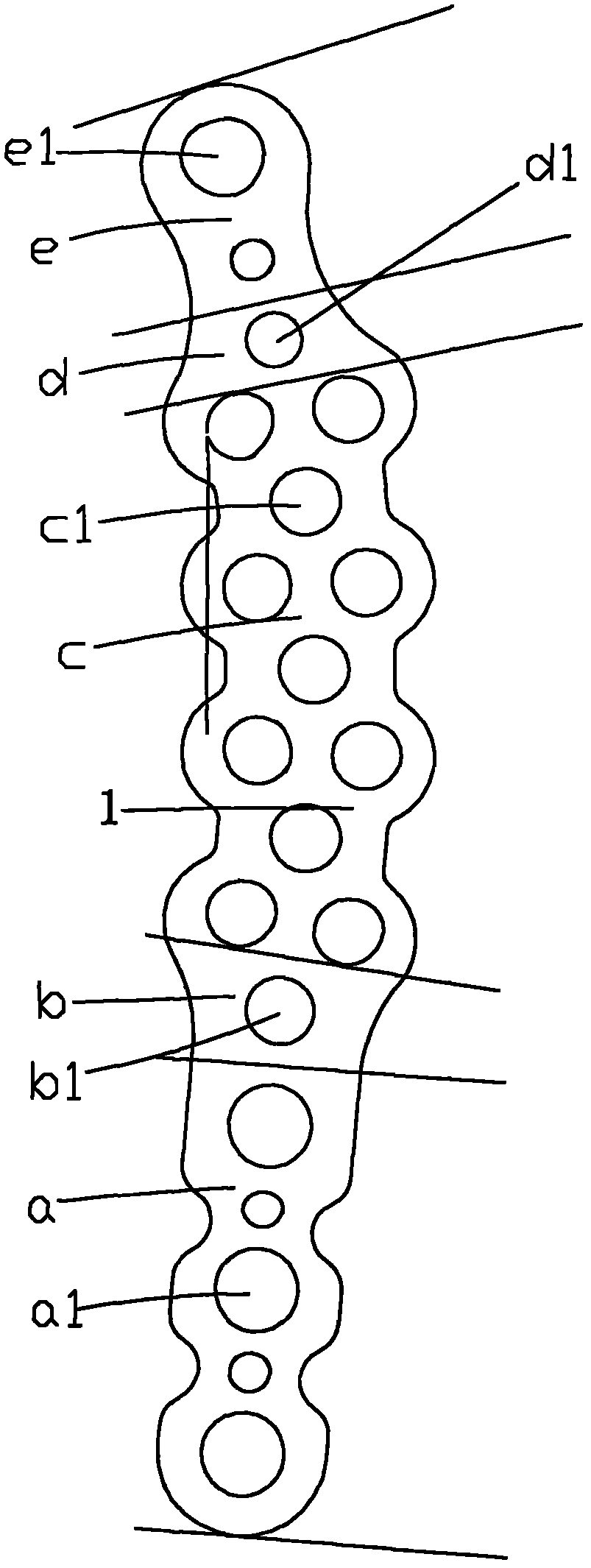

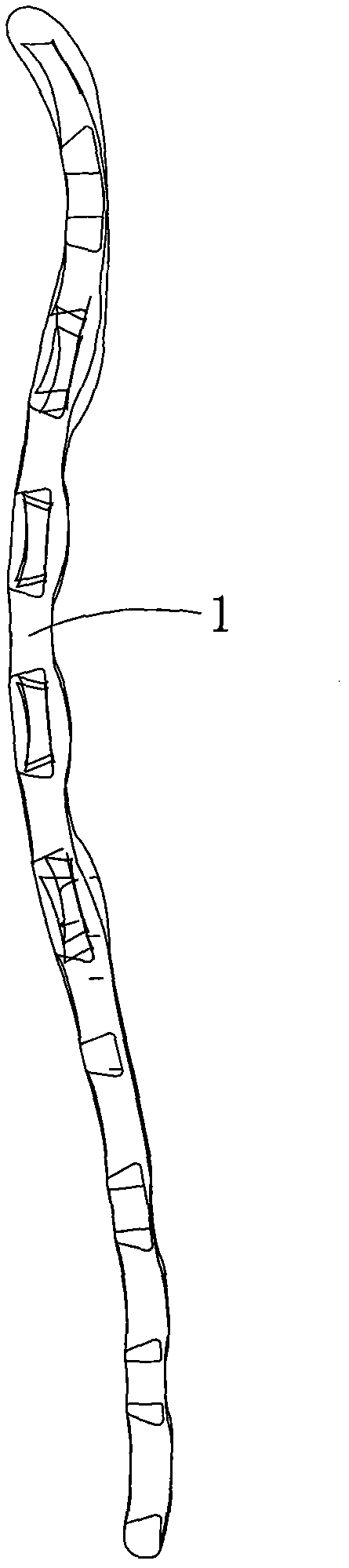

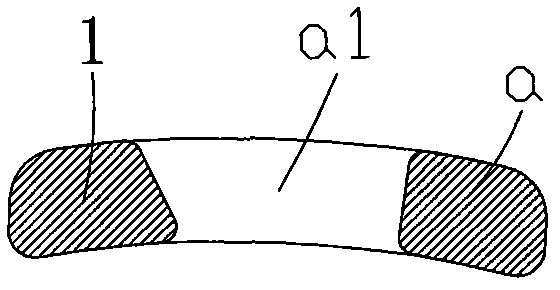

[0044] Such as Figure 1 to Figure 22 As shown, the icon numbers are explained as follows: steel plate body 1, self-locking screw 2, connector 21, first external thread 22, equal pentagonal wall surface 23, guide hole 24, auxiliary sleeve 3, working head 31, second External thread 32, handle 33, first locking block a, first self-locking hole a1, first positioning block b, first positioning hole b1, second locking block c, second self-locking hole c1, second The second positioning block d, the second positioning hole d1, the third locking block e, and the third self-locking hole e1.

[0045] In the embodiment of the present invention, the self-locking acetabular rear wall and post anatomical steel plate includes a steel plate body 1, a self-locking screw 2, and an auxiliary sleeve 3 for controlling the installation of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com