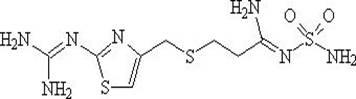

Famotidine composition for injection and preparation method thereof

A famotidine and composition technology, which is applied to the famotidine composition for injection and the field of preparation thereof, can solve the problems such as no improvement, and achieve the effects of improving molding performance, uniform and accurate content, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] prescription:

[0047] Famotidine 200g

[0048] L-Aspartic Acid 80g

[0049] Add water for injection to 20Kg

[0050] Preparation:

[0051] Put famotidine and L-aspartic acid in the preparation tank, add water for injection to 20Kg, stir to dissolve completely and mix evenly;

[0052] Sterile filtration, packing:

[0053] Filter the famotidine solution through a microporous membrane into a sterile room, dispense it into cillin bottles at a volume of 2ml / bottle, and half-stopper;

[0054] Vacuum Freeze Drying:

[0055] a. Pre-freezing: Put the subpackaged famotidine liquid into the freeze dryer, lower the temperature of the front box to below -30°C, and keep warm until the famotidine liquid is completely frozen;

[0056] b. Rear box refrigeration: use the compressor to cool the rear box cold trap, and keep the temperature of the rear box cold trap below -45°C;

[0057] c. Drying: Turn on the vacuum pump and the septum valve, start the sublimation dryin...

Embodiment 2

[0059] prescription:

[0060] Famotidine 200g

[0061] L-Aspartic Acid 80g

[0062] Add water for injection to 40Kg

[0063] Preparation:

[0064] Put famotidine and L-aspartic acid in the preparation tank, add water for injection to 40Kg, stir to dissolve completely and mix evenly;

[0065] Sterile filtration, packing:

[0066] Filter the famotidine solution into a sterile room through a microporous membrane, dispense it into cillin bottles at a volume of 4ml / bottle, and half-stopper;

[0067] Vacuum Freeze Drying:

[0068] a. Pre-freezing: Put the subpackaged famotidine liquid into the freeze dryer, lower the temperature of the front box to below -30°C, and keep warm until the famotidine liquid is completely frozen;

[0069] b. Rear box refrigeration: use the compressor to cool the rear box cold trap, and keep the temperature of the rear box cold trap below -45°C;

[0070] c. Drying: Turn on the vacuum pump and the septum valve, start the sublimation dryin...

Embodiment 3

[0072] prescription:

[0073] Famotidine 200g

[0074] Mannitol 400g

[0075] L-Aspartic Acid 80g

[0076] Add water for injection to 20Kg

[0077] Preparation:

[0078] Put famotidine, mannitol and L-aspartic acid in a preparation tank, add water for injection to 20Kg, stir to dissolve completely and mix evenly;

[0079] Sterile filtration, packing:

[0080] Filter the famotidine solution through a microporous membrane into a sterile room, dispense it into cillin bottles at a volume of 2ml / bottle, and half-stopper;

[0081] Vacuum Freeze Drying:

[0082] a. Pre-freezing: Put the subpackaged famotidine liquid into the freeze dryer, lower the temperature of the front box to below -30°C, and keep warm until the famotidine liquid is completely frozen;

[0083] b. Rear box refrigeration: use the compressor to cool the rear box cold trap, and keep the temperature of the rear box cold trap below -45°C;

[0084] c. Drying: Turn on the vacuum pump and the septu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com