System for treating organic exhaust gas by adsorptive-catalytic combustion

An organic waste gas, catalytic combustion technology, applied in chemical instruments and methods, dispersed particle separation, separation methods, etc., can solve the problems of adsorption time, catalytic combustion temperature waste heat recovery system difficult to control, equipment investment costs and operating costs high. The effect of reducing energy consumption, reducing gas leakage and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

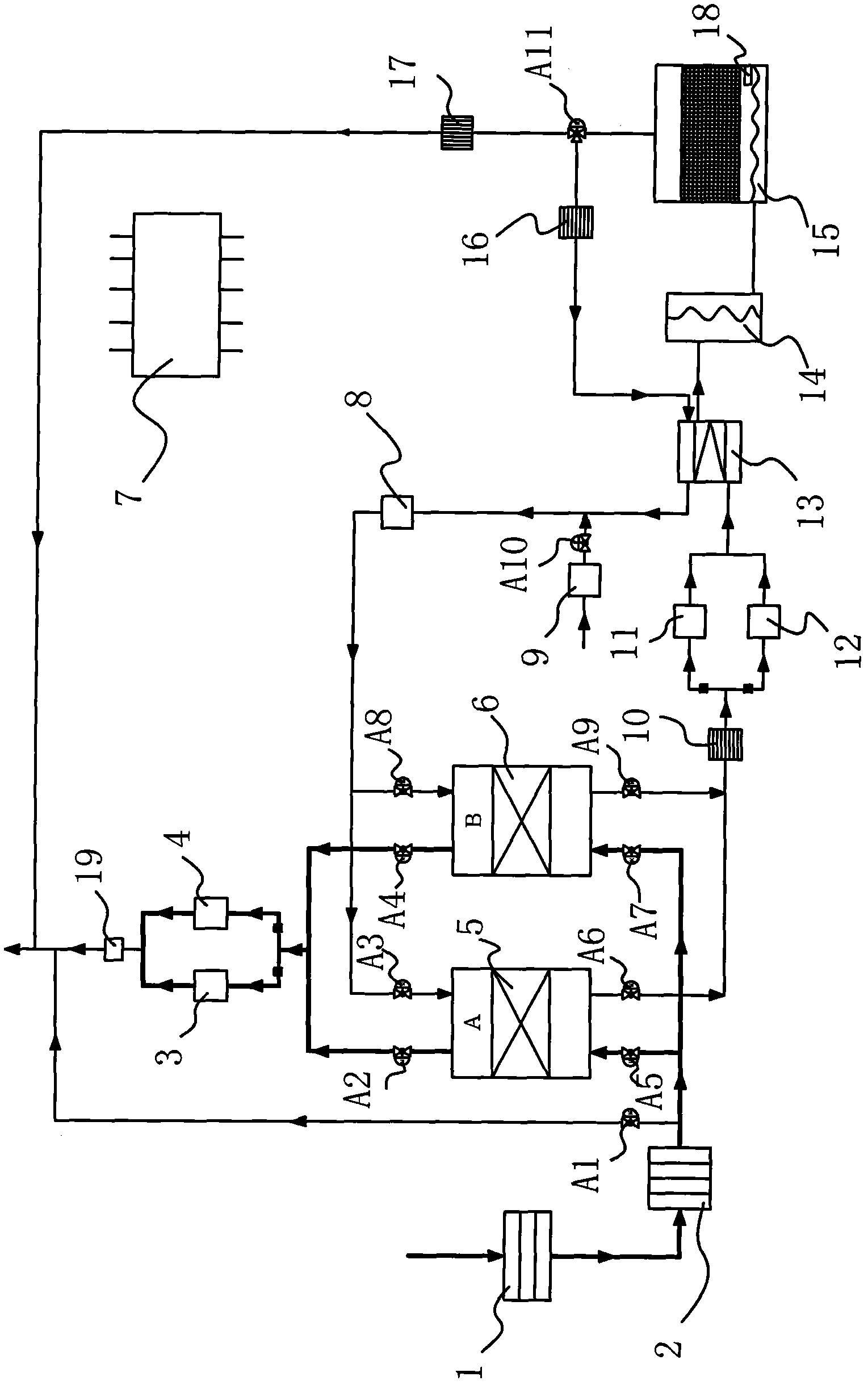

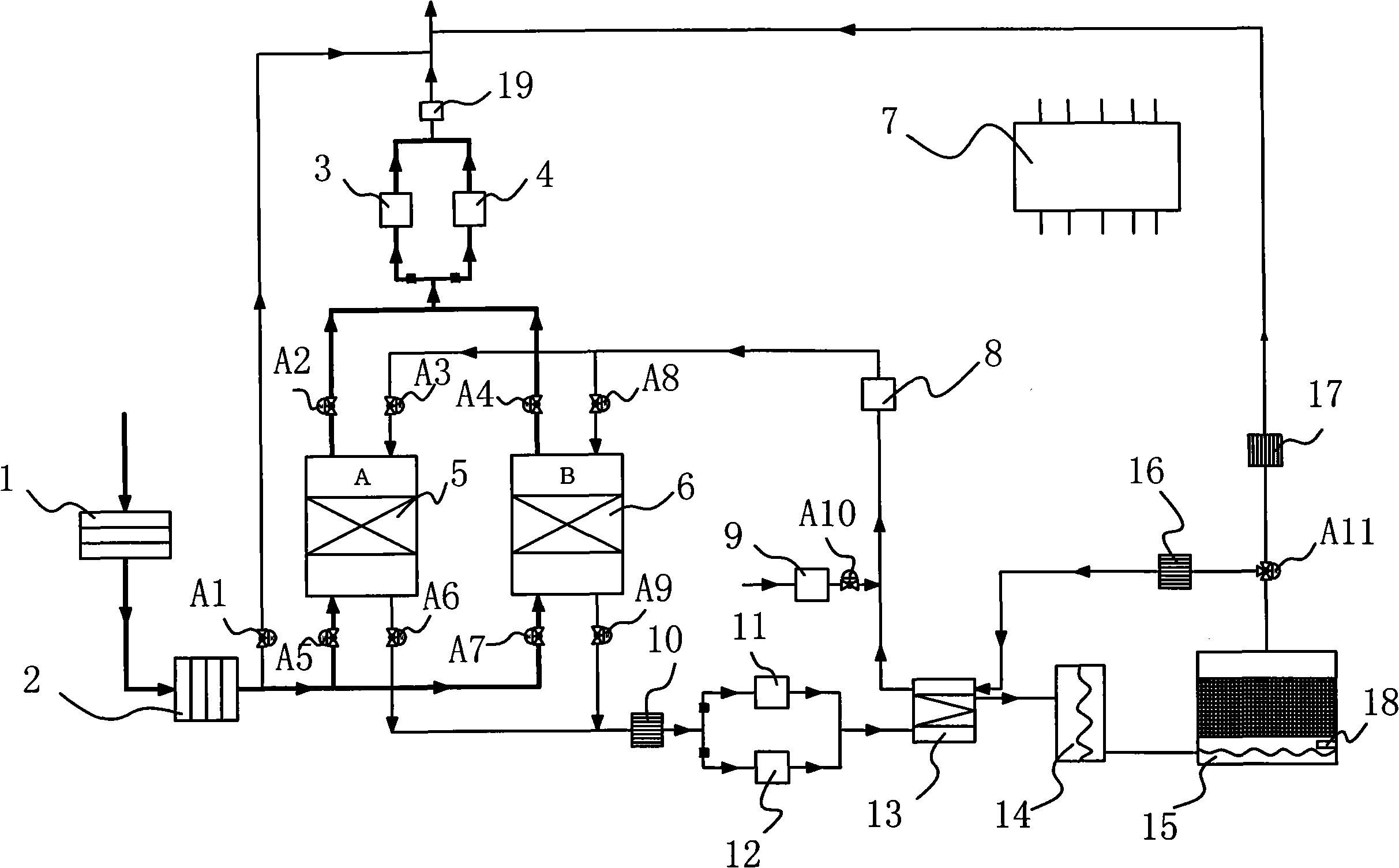

[0019] The present invention will be described in further detail below in conjunction with the embodiments and with reference to the accompanying drawings.

[0020] A trial production test was carried out on the exhaust gas from spray painting in a furniture factory.

[0021] An adsorption-catalytic combustion system for treating spray paint exhaust gas, including a pretreatment filter 1 and an air distributor 2 connected to the paint spray exhaust gas sucked into a furniture factory, a parallel main adsorption fan 3 and an auxiliary adsorption fan 4 that discharge the adsorbed exhaust gas, And the parallel pipe is connected between the air distributor 2 and the main adsorption fan 3 and the auxiliary adsorption fan 4. Gas monitoring equipment 19 is connected to the exhaust pipe, and the gas monitoring equipment 19 is electrically connected to the control device 7. The entrances of the main fixed adsorption bed 5 and the auxiliary fixed adsorption bed 6 pass through the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com