Automatic winding device with swinging mechanism for multi-wire cutting machine

A multi-wire cutting machine and automatic winding technology, applied in the direction of fine work devices, work accessories, stone processing equipment, etc., can solve the problems of error-prone, long time-consuming, etc., and achieve small warpage deformation, high efficiency, and production efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

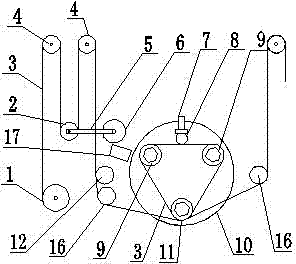

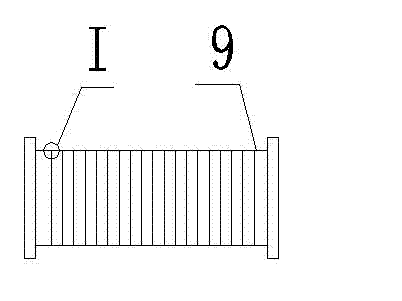

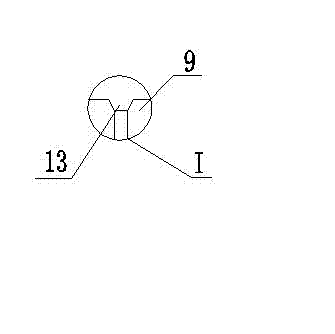

[0026] by attached figure 1 , figure 2 and image 3 As shown, an automatic winding device for a multi-wire cutting machine with a swing mechanism, including a cutting wire 3 wound on a pay-off wheel 1, a guide wheel 4 is arranged above the pay-off wheel 1, and the wire wheel 4 is connected by a cutting wire 3 The balance wheel 2, the balance wheel 2 is connected to another guide wheel 4 above through the cutting line 3, the guide wheel 4 is connected to the winding wheel 12 through the cutting line 3, the support wheel 16 is set under the winding wheel 12, and the cutting line 3 is wound The wheel 12 and the support wheel 16 are connected to the driven work roll 11; the driven work roll 11 and the two active work rolls 9 are vertically arranged on the swing disk 10 in a triangle shape, and the cylindrical surfaces of the driven work roll 11 and the drive work roll 9 There are several annular winding grooves 13; the balance wheel 2 is connected to the swing rod 5, and the sw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com