Preparation method of polymeric ferric aluminous sulphate by using pyrite wastewater and treatment sludge

A technology for polymerizing ferric aluminum sulfate and wastewater treatment, applied in the direction of ferric sulfate, etc., can solve the problems of small residual chromaticity, small flocculation volume, large residual chromaticity, etc., achieve obvious social and environmental benefits, solve environmental pollution problems, realize The effect of resource processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

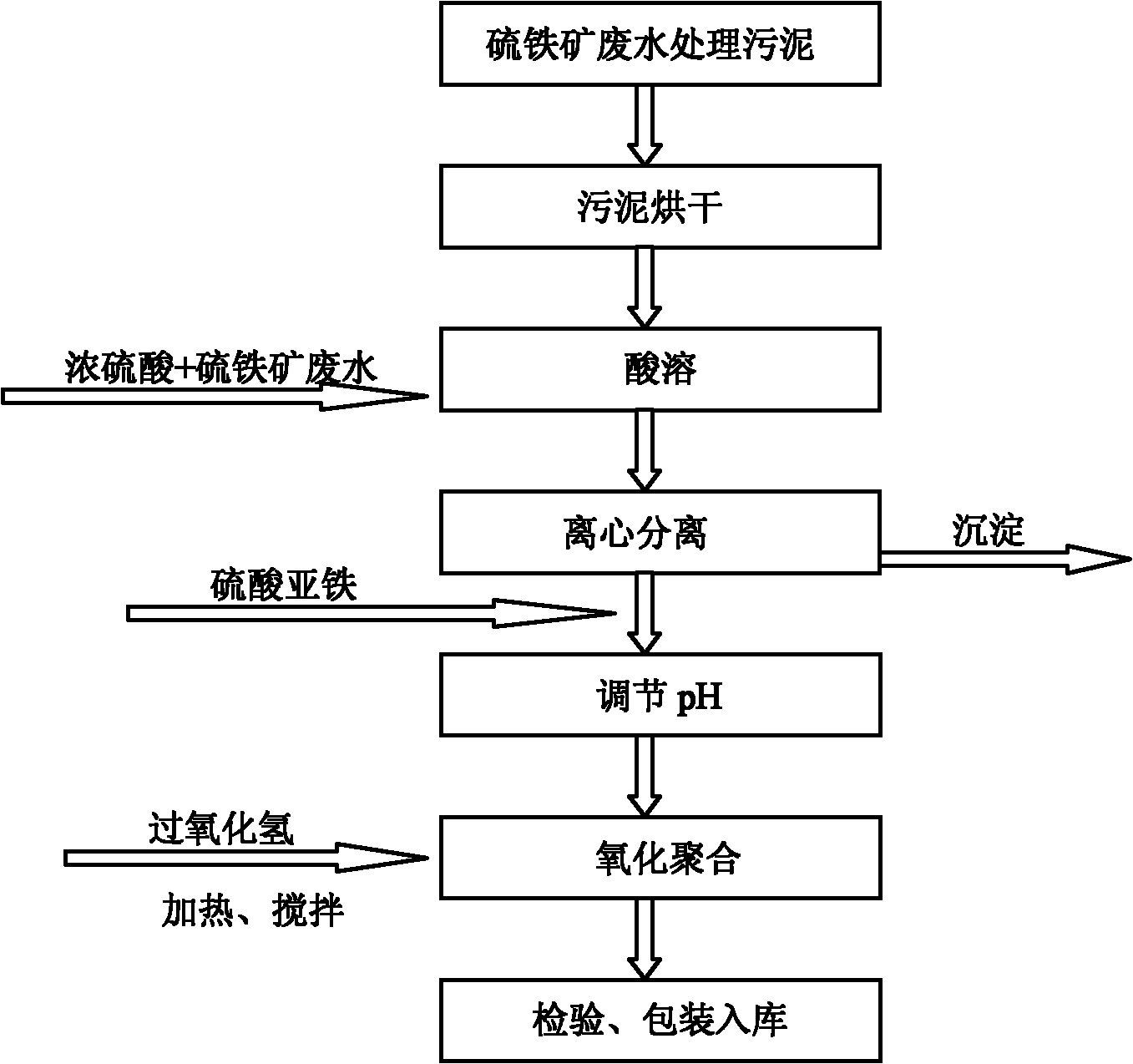

Method used

Image

Examples

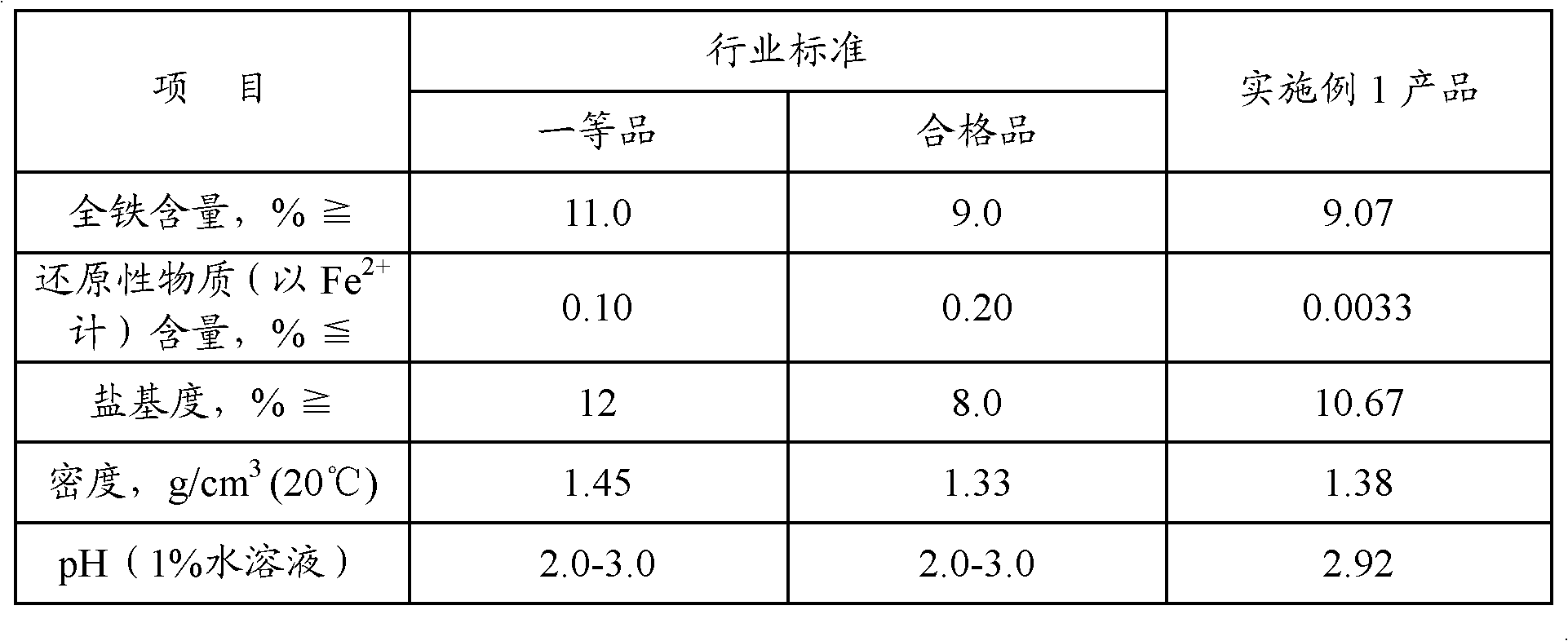

Embodiment 1

[0025] Take 500g of pyrite wastewater treatment sludge, put it into a constant temperature oven, bake it at 80°C for 48 hours, and grind it to obtain dry sludge powder, which is ready for use. Take 50g of dry sludge powder, add 170mL of acid solution (volume ratio of pyrite wastewater to concentrated sulfuric acid 9:1), 70°C, electric stirring for 20min, centrifugation for 20min, and discard the precipitate. Move the acid extract to the reactor, add 80 g of ferrous sulfate heptahydrate, and adjust the pH value of the acid extract to 0.9 with concentrated sulfuric acid with a mass concentration of 98%. Heat in a water bath at 45°C, add 30mL of 30% hydrogen peroxide solution (0.288molH 2 o 2 ), the rotating speed of the electric stirrer was 150r / min, the reaction time was 1.5h, and 199.5g of polyferric aluminum sulfate was obtained.

Embodiment 2

[0027] Concentrated sulfuric acid with a mass concentration of 98% was added to adjust the pH value of the acid extract to 0.7, and other operations were the same as in Example 1 to obtain 198.6 g of polyferric aluminum sulfate.

Embodiment 3

[0029] Heated in a water bath to 55° C., and other operations were the same as in Example 1 to obtain 188.1 g of polyferric aluminum sulfate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com