Preparation method for synthesizing propionic acid by carbonylation

A technology of chemical synthesis and propionic acid, applied in the direction of carbon monoxide reaction to prepare carboxylic acid, chemical instruments and methods, organic compound/hydride/coordination complex catalyst, etc., can solve the problem of low activity and achieve improved activity and stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

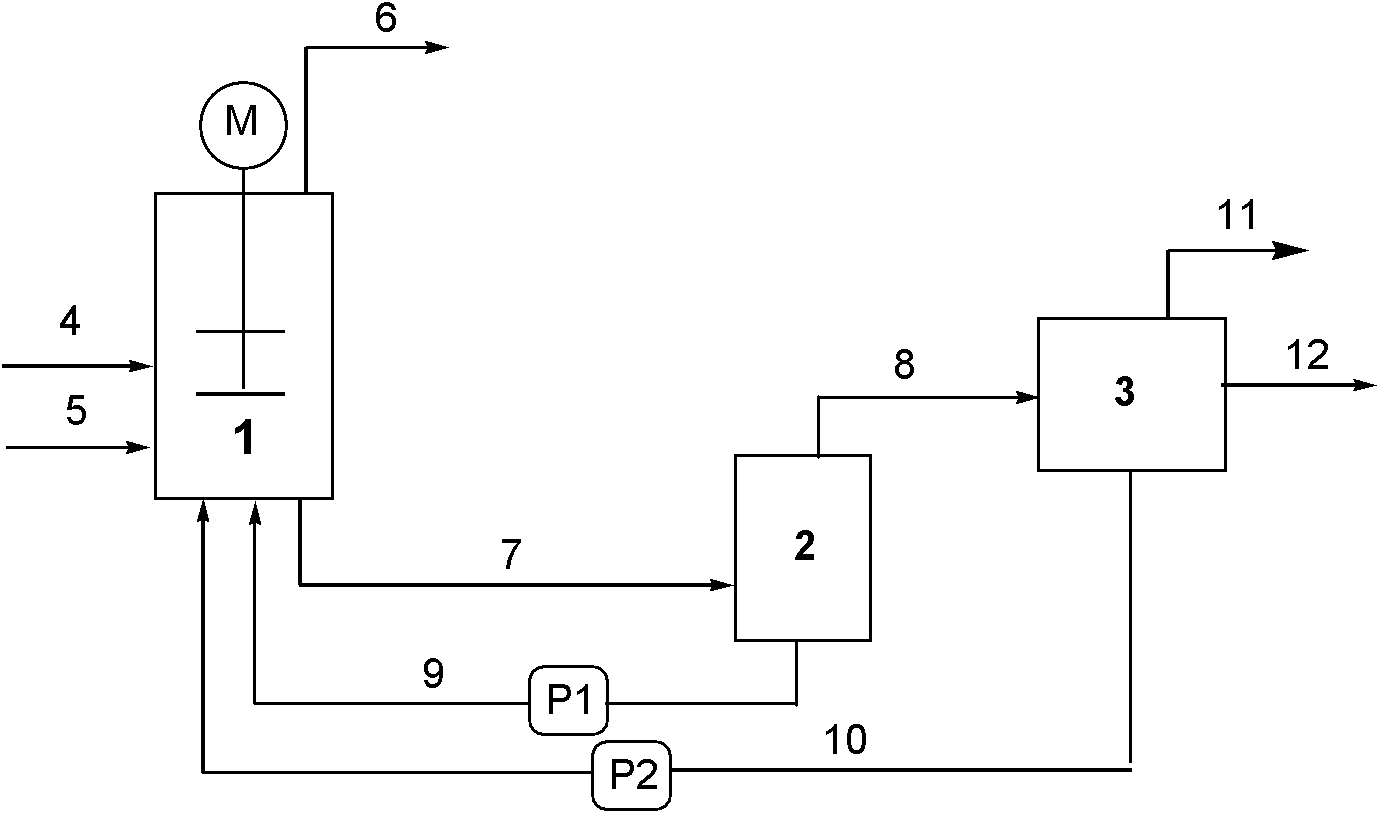

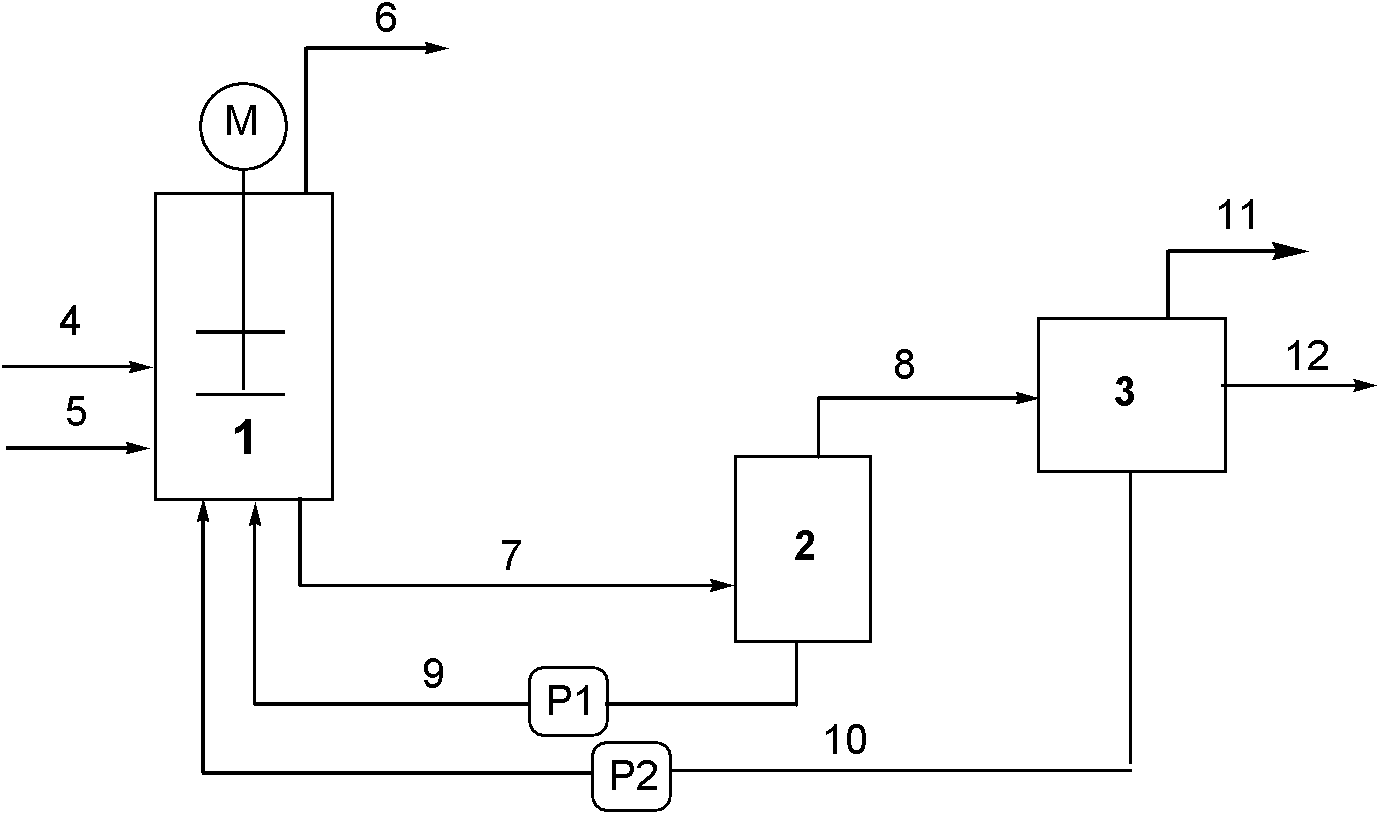

Method used

Image

Examples

Embodiment 1

[0032] Add iridium acetate (iridium content 48wt%) 313mg, ruthenium iodide (ruthenium content 21wt%) 1.89g, lithium iodide 168mg, iodoethane 15g, distilled water in the 200ml zirconium material autoclave that pressure gauge is housed under air atmosphere 15g, ethyl propionate 37.5g, and the rest is 55.2g of propionic acid solvent, with a total weight of 125 grams. Keeping the reaction temperature at 190° C. and the reaction pressure at 30 bar, the calculated carbonylation rate when the weight ratio of ethyl propionate in the reaction liquid is 15% is 3.2 mol / Lh.

Embodiment 2

[0034] Add iridium acetate (iridium content 48wt%) 313mg, indium iodide (indium content 23wt%) 3.89g, lithium iodide 168mg, iodoethane 15g, distilled water in the 200ml zirconium material autoclave that pressure gauge is housed under air atmosphere 15g, ethyl propionate 37.5g, and the rest is propionic acid solvent 53.3g, total weight 125 grams. Keeping the reaction temperature at 190° C. and the reaction pressure at 30 bar, the calculated carbonylation rate when the weight ratio of ethyl propionate in the reaction liquid is 15% is 1.8 mol / Lh.

Embodiment 3

[0036] Add iridium acetate (iridium content 48wt%) 313mg, subplatinum iodide (platinum content 43wt%) 1.42g, lithium iodide 168mg, iodoethane 15g in the zirconium material autoclave that pressure gauge is housed in 200ml under air atmosphere, 15g of distilled water, 37.5g of ethyl propionate, and 55.8g of propionic acid solvent, the total weight is 125 grams. Keeping the reaction temperature at 190° C. and the reaction pressure at 30 bar, the carbonylation rate when the weight ratio of ethyl propionate in the reaction solution is 15% is calculated to be 2.5 mol / Lh.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com