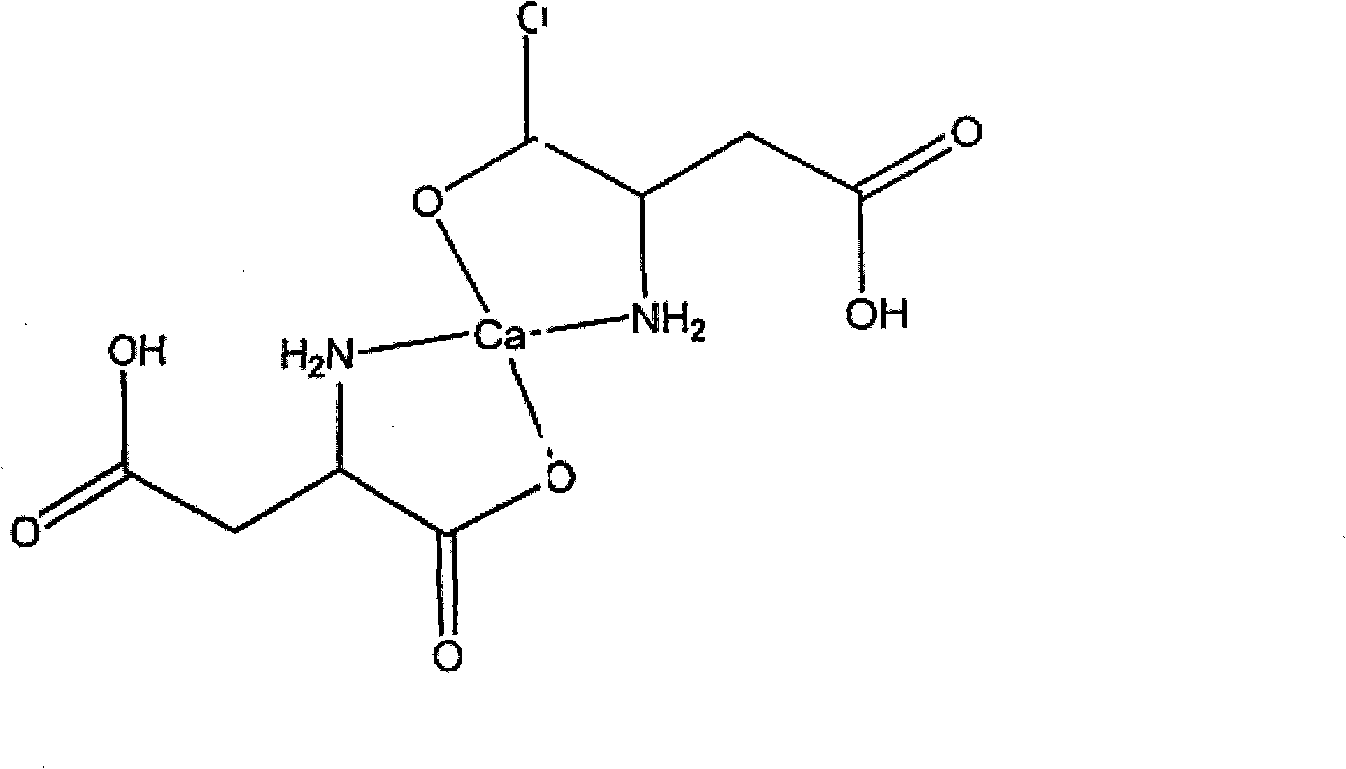

Novel production process of nanometer calcium amino acid chelate with high efficiency

An amino acid, chelated calcium technology, applied in the preparation of organic compounds, organic chemistry, cyanide reaction preparation and other directions, can solve the problems of insoluble, affecting calcium absorption, difficulty in absorption, etc., and achieve stable molecular structure and bioavailability. High and good solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

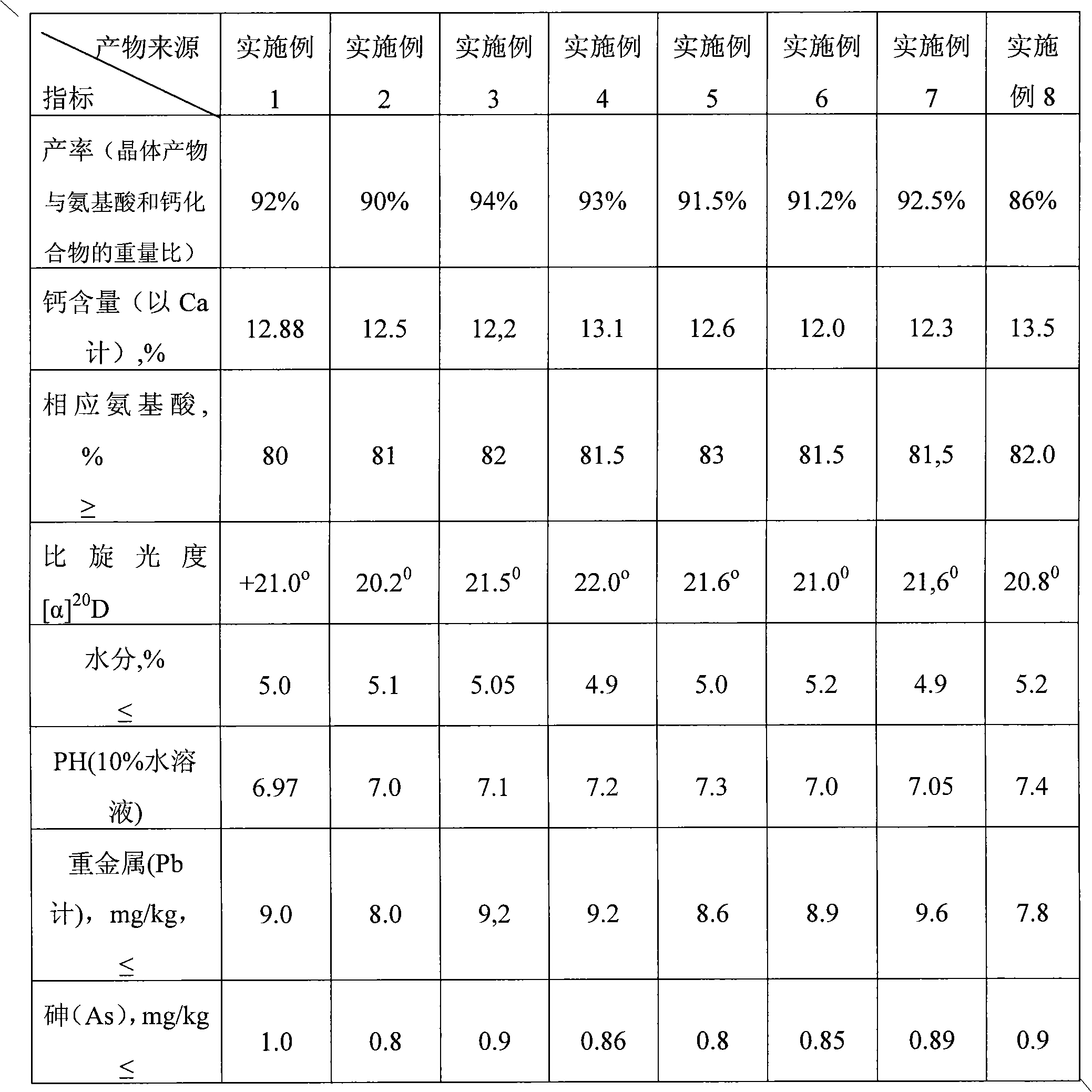

Embodiment 1

[0023] Selected Ca(OH) 2 and L-aspartic acid, according to the molar ratio of 1: 2.2 ingredients, the reactant and purified water are mixed in a weight ratio of 30: 80, fully stirred, the acidity of the suspension is adjusted to PH7.4, through colloid milling, Processed by a homogenizer to fully dissolve and disperse the reactants, and then filter to remove larger particles in the suspension to ensure that the solid particle size in the suspension is less than 30 microns, and then pump the reactant suspension into the SY-NANO high pressure In the fluid nanomill, the working pressure is controlled at about 110MPA, the rotational speed is 300r / min, the temperature is 70-90°C, the ultrasonic frequency is 50-70Hz, and the feeding speed is 200 liters per hour. The entire chelation reaction process is completed in the nano-physical and chemical chamber. , to obtain a clear L-aspartic acid chelated calcium solution, and the reaction solution was spray-dried to obtain a white crystal ...

Embodiment 2

[0025] except Ca(OH) 2 and L-aspartic acid in a molar ratio of 1: 2.5, other conditions and operating procedures are the same as in Implementation 1.

Embodiment 3

[0027] In addition to Ca(OH) 2 Replaced by CaO, except that CaO and L-aspartic acid are dosed in a molar ratio of 1:2.2, other conditions and operating procedures are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com