Preparation method of aronia melanocarpa beer

A production method, the technology of berry beer, which is applied in the direction of beer fermentation method, beer brewing, method based on microorganisms, etc., can solve the problems of high alcohol content and residual sugar content, and achieve the effect of easy absorption and avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Manufacture of berry juice and berry powder.

[0025] Put 1000g of frozen berry fruit at 10 degrees for 24 hours, thaw and ripen, then use an extruder to extract berry juice with a sugar content of 12brix; after squeezing the berry fruit, dry the remaining peel and seeds , can be sun-dried, air-dried or hot-air-dried, and the dried berry peel and seeds are crushed into berry powder in a grinder.

Embodiment 2

[0027] The manufacture of oldberry beer with different mixing ratios of beer juice and oldberry juice.

[0028] Saccharify the malt with glucoamylase for 2 hours to obtain a saccharification solution; add the above-mentioned berry powder to the saccharification solution, and the weight of the berry powder accounts for 1% of the weight of the saccharification solution; after mixing evenly, boil for 3 hours to obtain beer juice;

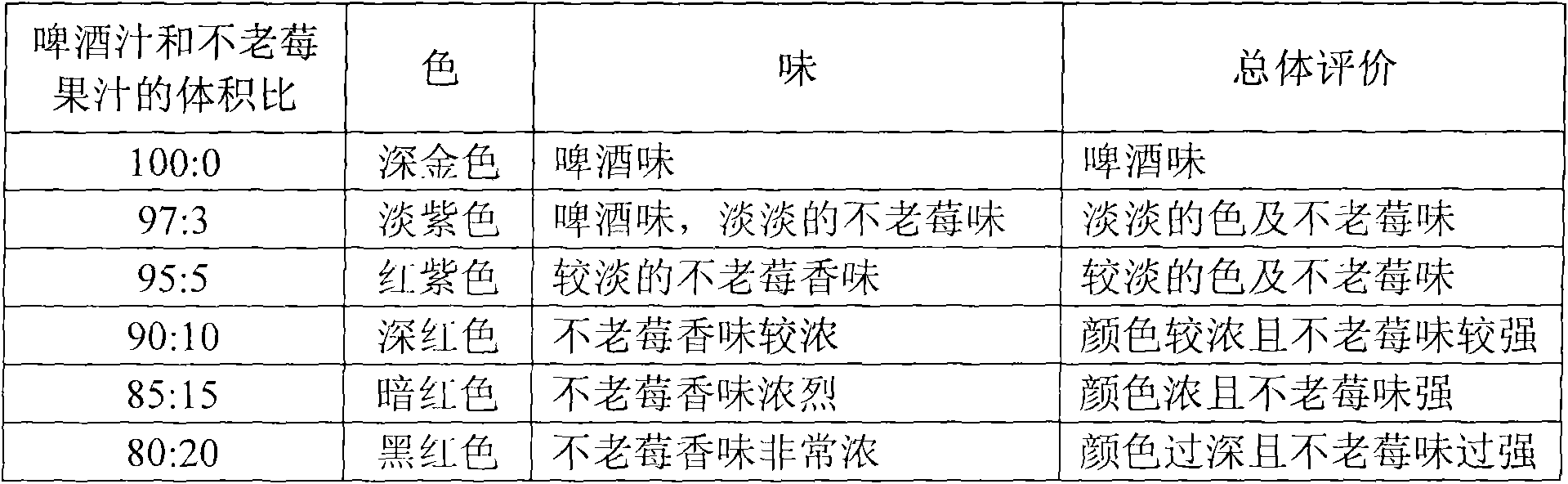

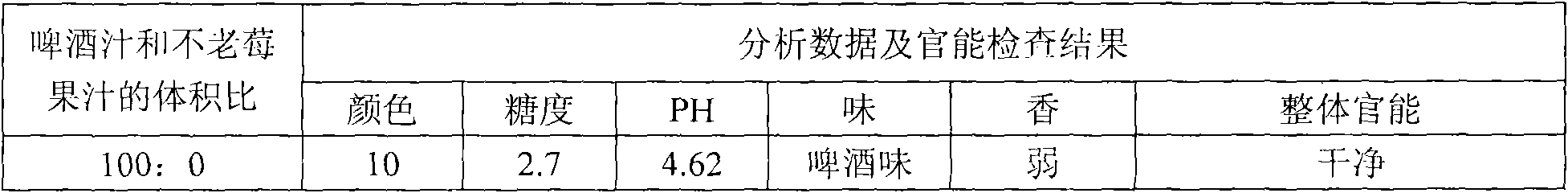

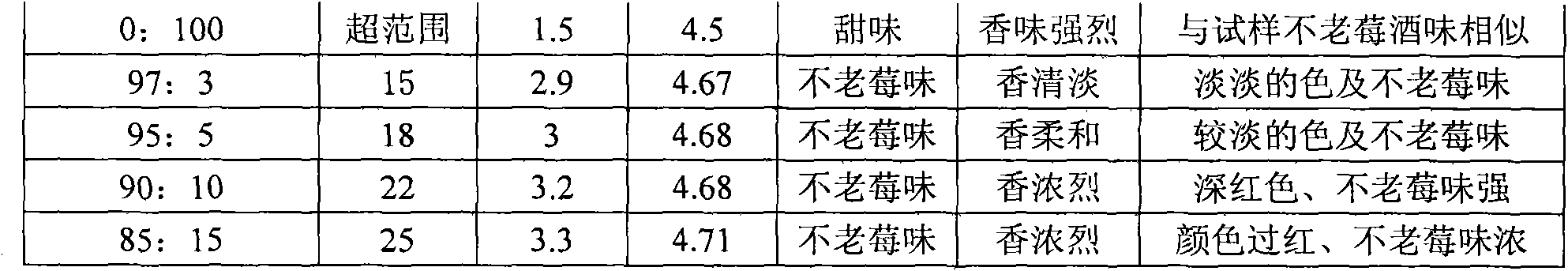

[0029] In order to obtain the proper mixing ratio of old berry juice and beer juice. The beer juice and berry juice made above are mixed in proportions of 100:0; 97:3; 95:5; 90:10; 85:15; The sensory inspection method was confirmed, and the results are shown in Table 1.

[0030] Table 1

[0031]

[0032] As can be seen from Table 1, the appropriate added volume ratio of berry juice is 3-15%, preferably 5-10%.

[0033] Adding berry juice during the fermentation process of beer juice may change the composition and composition characteristics of bee...

example 31

[0041] Example 3.1, Manufacture of Oldberry Beer.

[0042]Add 4,532g of malt to 19,000ml of water, saccharify for 3 hours, and then filter. The filtrate is heated to 100°C. During this process, 33g of the berry powder in Example 1 is added, and boiled for 2 hours to make beer juice. During the cooking process, the unique color and ingredients of the old berry are soaked out of the old berry powder.

[0043] After the beer juice is precipitated, the sediment is removed. During the precipitation process, 1080ml of the old berry juice prepared in the above example 1 is added. The beer juice after the sediment is removed is cooled to 14°C by a cooler, and 15kg of yeast is added. Thereafter, after 6 days of fermentation in the fermentation tank, it is moved to the maturation tank, and after 15 days of maturation, the old berry beer is made.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com