Bisoxazoline chain-extending polylactic acid polyhydric alcohol with low-acid value and preparation method for bisoxazoline chain-extending polylactic acid polyhydric alcohol with low-acid value

A bisoxazoline chain-extended polylactic acid and polylactic acid polyol technology, which is applied in the field of preparation of low acid value polylactic acid polyols, can solve problems such as high acid value and reduced reactivity of polylactic acid polyols, and achieve simple process , low production cost, enhanced reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] A kind of preparation method of low acid value bisoxazoline chain-extended polylactic acid polyol, it comprises the steps:

[0023] S1: Prepare polylactic acid with a theoretical molecular weight of 500-4000 and an acid value of 3.50-14.10;

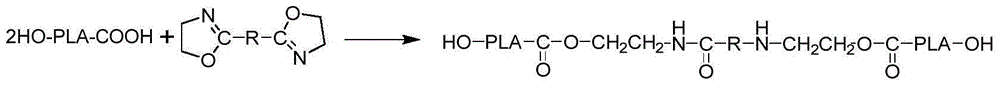

[0024] S2: Add bisoxazoline to the polylactic acid and conduct a heating reaction under the protection of nitrogen or an inert gas to obtain a polylactic acid polyol with an acid value less than or equal to 3.

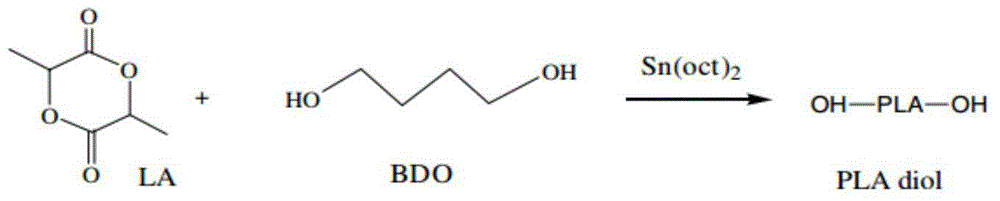

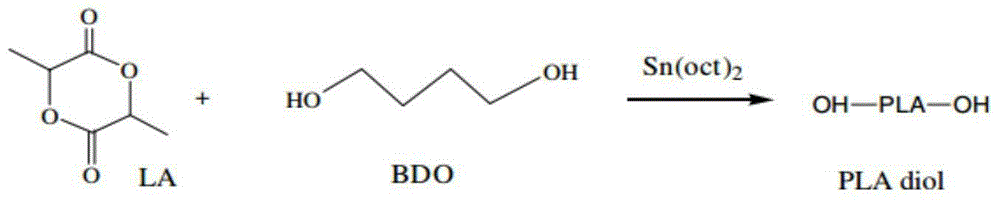

[0025] In step S1, the preparation method of the polylactic acid is not limited, and may include the direct polycondensation method of lactic acid, the ring-opening polymerization method of lactide and the bulk polymerization method of lactic acid initiated by polyol. Preferably, the polylactic acid is polymerized by ring-opening polymerization of lactide, and its chemical reaction equation is:

[0026]

[0027] The catalyst is one of iron chloride, aluminum chloride, butyllithium, sodium alkoxide, potassium alkoxide st...

Embodiment 1

[0036] A preparation method of low acid value polylactic acid polyols, comprising the following steps (the following parts are parts by weight):

[0037] Preparation of polylactic acid with a theoretical molecular weight of 500: Add 47.20g of 1,4-butanediol, 216.02g of lactide, and 0.11g of stannous octoate to a round-bottomed flask, vacuumize and replace with nitrogen for 3 times. Stir and heat up to 140°C, and react at 140°C for 24 hours to obtain 261.56g of polylactic acid with a theoretical molecular weight of 500 and an acid value of 3.50.

[0038] Modification of polylactic acid: Add 70.32g of polylactic acid prepared by the above method and 1.02g of 2,2'-(1,3-phenylene)-bisoxazoline into a round bottom flask, vacuumize and replace with nitrogen for 3 times , under the condition of nitrogen protection, the temperature was raised to 140°C with continuous stirring, and the reaction was carried out at 140°C for 1.0 hour to obtain a polylactic acid polyol with a low acid val...

Embodiment 2

[0040] A preparation method of low acid value polylactic acid polyols, comprising the following steps (the following parts are parts by weight):

[0041] The preparation of polylactic acid with a theoretical molecular weight of 1000: add 28.40g 1,4-butanediol, 288.65g lactide, 0.14g stannous octoate to a round bottom flask, vacuumize and replace with nitrogen for 3 times, continuously under the protection of nitrogen Stir and heat up to 140°C, and react at 140°C for 24 hours to obtain 301.33g of polylactic acid with a theoretical molecular weight of 1000 and an acid value of 4.00.

[0042] Modification of polylactic acid: Add 52.20g of polylactic acid prepared by the above method and 1.48g of 2,2'-(1,3-phenylene)-bisoxazoline into a round bottom flask, vacuumize and replace with nitrogen for 3 times , under the condition of nitrogen protection, the temperature was raised to 165°C with constant stirring, and the reaction was carried out at 165°C for 1.5 hours to obtain a polyla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com