Preparation method of barium titanium silicate crystal

A barium silicate and crystal technology is applied in the field of preparation of barium and titanium silicate crystals, which can solve the problems of inability to purchase crystals in the market, high requirements, and difficulty in realization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Take reaction formula (1) as an example: but not limited to reaction formula (1)

[0031] BaO+SiO 2 +TiO 2 →Ba 2 TiSi 2 o 8 Synthesis of Ba 2 TiSi 2 o 8 compound, the specific steps are as follows:

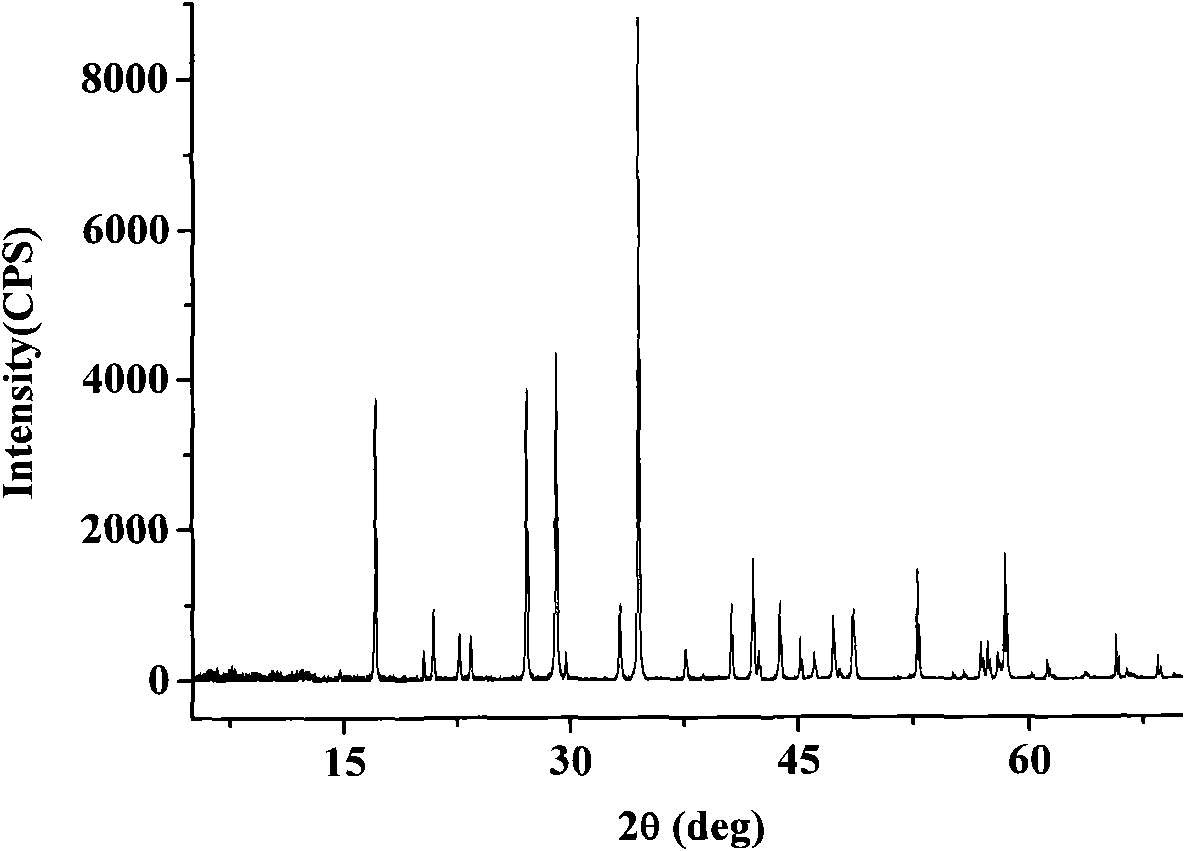

[0032] BaO, SiO 2 、TiO 2 Put it into a mortar with a stoichiometric ratio of 2:2:1, mix it evenly and grind it carefully, then put it into a corundum crucible with an opening of Φ200mm×200mm, press it tightly, put it into a muffle furnace, and slowly heat up to 450°C , constant temperature for 5 hours, try to drive out the gas, take out the crucible after cooling, grind the sample evenly, then put it in the crucible, keep it in the muffle furnace at 720°C for 5 hours, wait until the temperature drops to room temperature, take it out carefully Grind, keep the temperature at 1200°C for 24 hours again, put it into a mortar after cooling, and grind it slightly to get completely sintered barium titanium silicate (Ba 2 TiSi 2 o 8 ) compound, and the product is subjec...

Embodiment 2

[0036] Take reaction formula (3) as an example: but not limited to reaction formula (3)

[0037] Ba(NO 3 ) 2 +SiO2 2 +TiO 2 →Ba 2 TiSi 2 o 8 +NO 2 ↑ Synthesis of Ba 2 TiSi 2 o 8 Compound, specific operation steps are carried out according to embodiment 1:

[0038] The synthesized Ba 2 TiSi 2 o 8 Compounds and Fluxes LiF and B 2 o 3 Massive Ba 2 TiSi 2 o 8 :LiF:B 2 o 3 = 1:4:2 for mixing, put into an open platinum crucible of Φ40mm×30mm, heat up to 1200°C, keep the temperature down to 890°C after 30 hours, and cut the optimized Ba 2 TiSi 2 o 8 The seed crystal is fixed on the lower end of the seed rod with a platinum wire, and the seed crystal is introduced into the crucible from the small hole on the top of the furnace, immersed in the liquid surface, and the seed crystal rotates reversibly at a rate of 50 rpm, and the rotation time in each direction is 7 minutes. The time interval is 0.8 minutes, keep the temperature for 20 minutes, quickly drop to 880°...

Embodiment 3

[0041] Take reaction formula (6) as an example: but not limited to reaction formula (6)

[0042] Ba(OH) 2 +SiO2 2 +TiO 2 →Ba 2 TiSi 2 o 8 +H 2 O ↑ Synthesis of Ba 2 TiSi 2 o 8 Compound, specific operation steps are carried out according to embodiment 1:

[0043] The synthesized Ba 2 TiSi 2 o 8 Compounds and Fluxes LiF and H 3 BO 3 Massive Ba 2 TiSi 2 o 8 :LiF:H 3 BO 3 = 1:5:2 for mixing, put into an open platinum crucible of Φ40mm×30mm, heat up to 1200°C, keep the temperature for 30 hours and then cool down to 870°C, the optimized Ba 2 TiSi 2 o 8 The seed crystal is fixed on the lower end of the seed rod with a platinum wire, and the seed crystal is introduced into the crucible from the small hole on the top of the furnace, immersed in the liquid surface, and the seed crystal rotates reversibly at a rate of 30 rpm, and the rotation time in each direction is 5 minutes. The time interval is 0.6 minutes, keep the temperature for 20 minutes, quickly drop to 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com