Spraying processing method and spraying machine for fabric dyeing and finishing

A processing method and technology of a spraying machine, applied in the direction of spray discharge device, spray/jet textile material treatment, etc., can solve the problems of complicated equipment and increased production cost, and achieve low cost, reduced water consumption, and high deposition rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

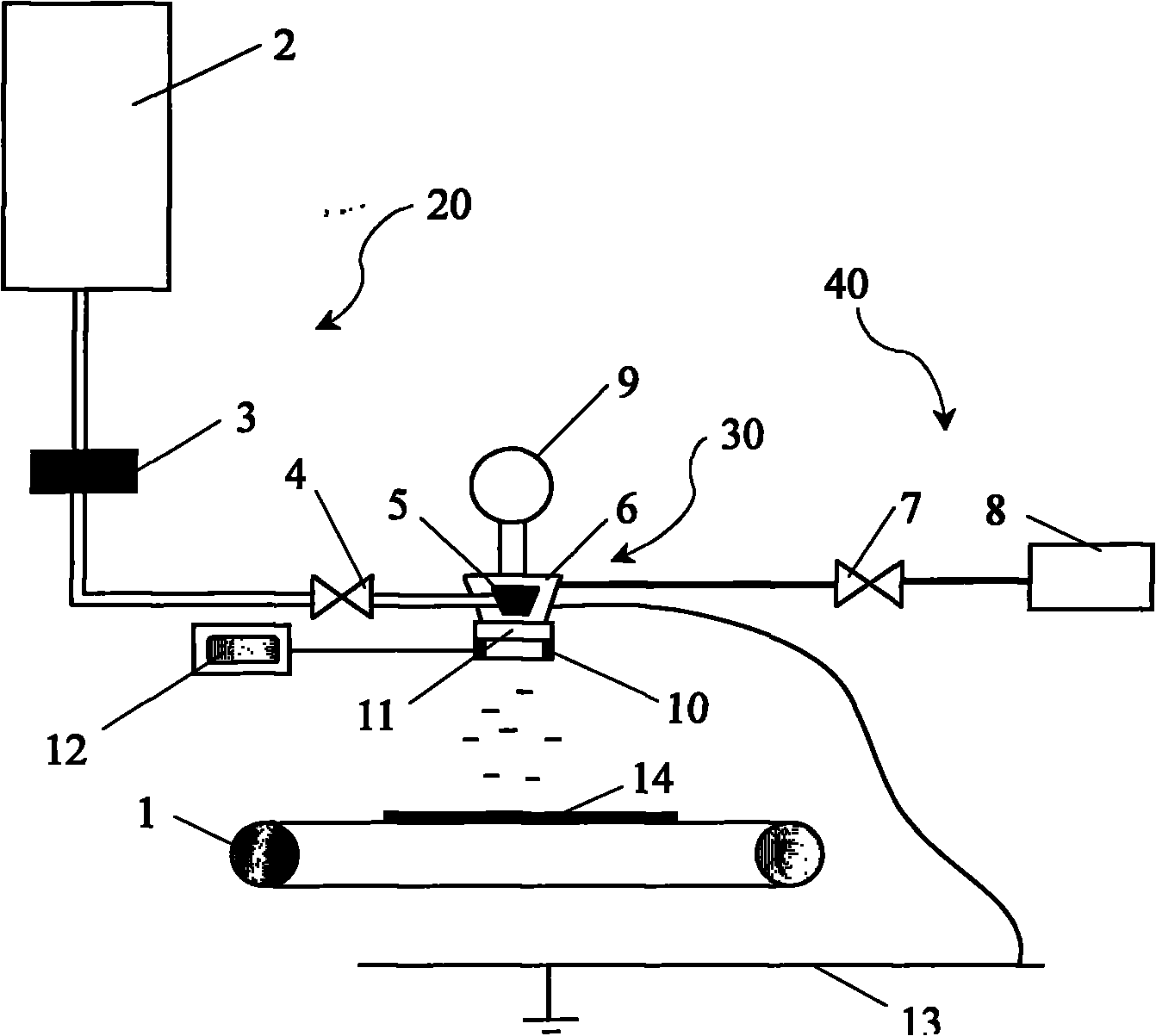

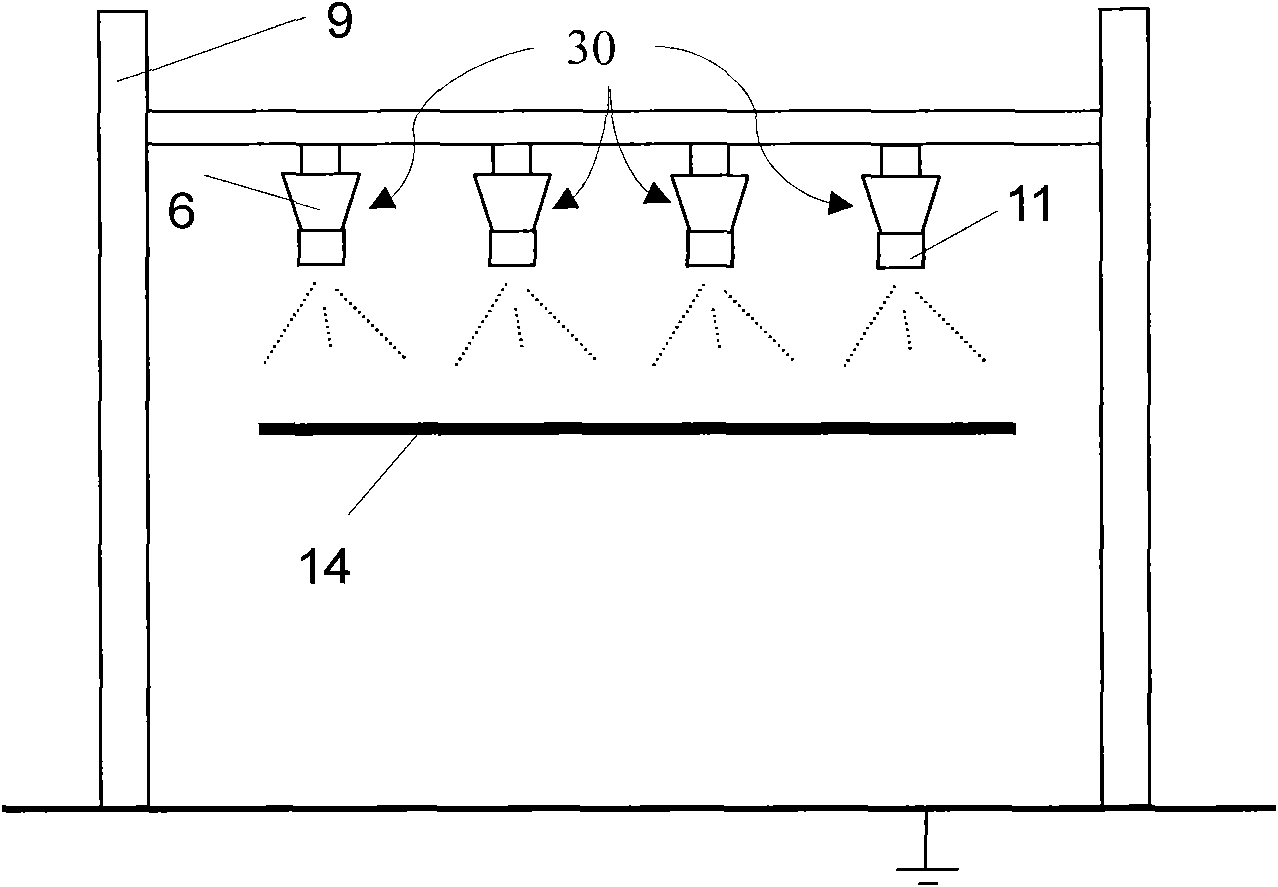

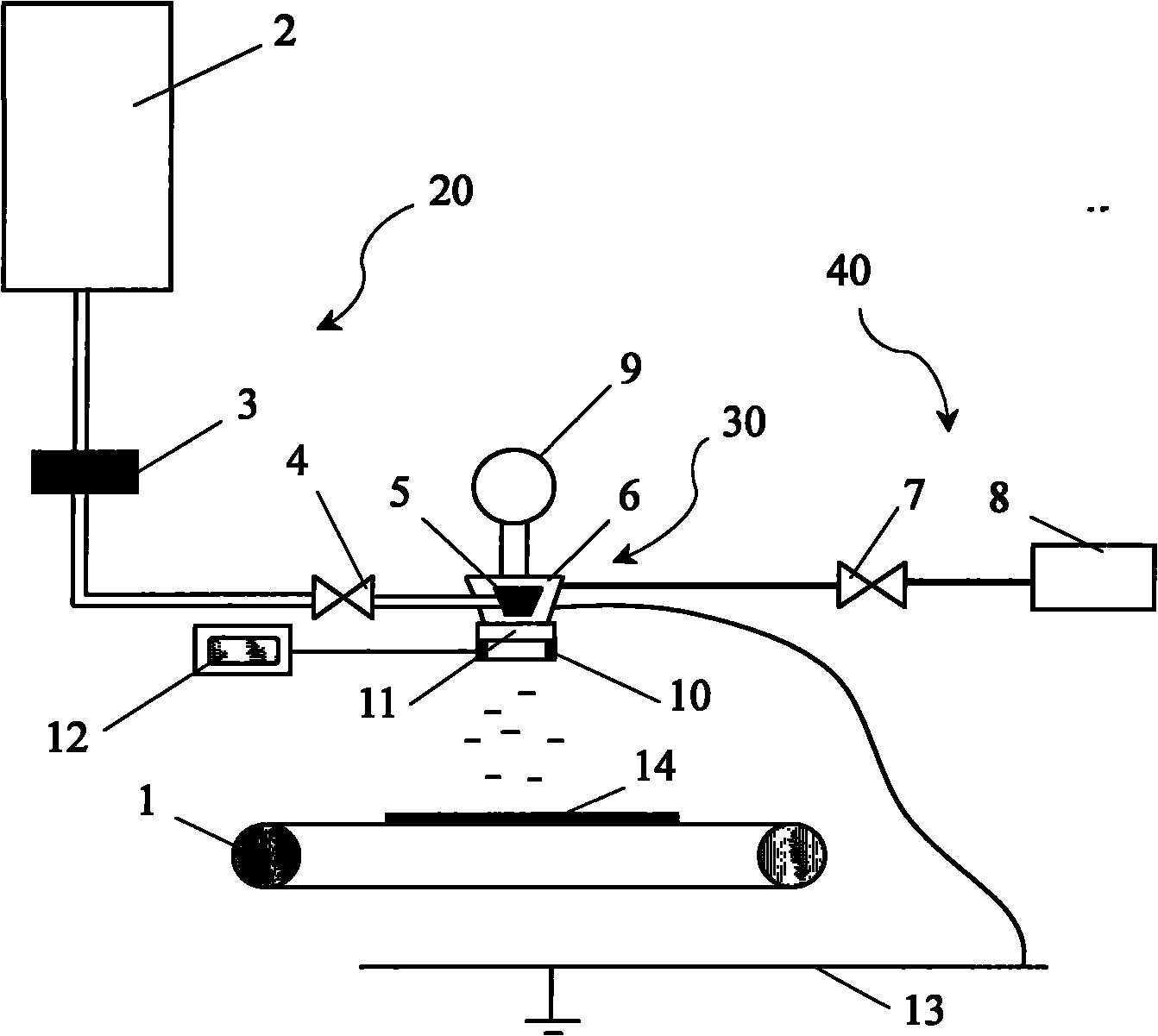

[0044] Such as figure 1 , 2 As shown, the air-assisted electrostatic atomizing spray machine of the present invention includes a fabric conveying device 1, a dyeing and finishing auxiliary agent conveying system 20, an electrostatic atomizing dyeing and finishing device 30, an aerodynamic conveying system 40, and a gantry 9. The dyeing and finishing auxiliary agent delivery system 20 includes a liquid storage tank 2, the electrostatic atomization dyeing and finishing device 30 includes an atomizer 5, an aerodynamic nozzle 6, a corona discharge chamber 11, and the aerodynamic delivery system 40 includes an air compressor 8 and a fabric 14. Located on the fabric conveying device 1.

[0045] The dyeing and finishing auxiliary agent in the liquid storage tank 2 maintains a certain liquid level, and the liquid level of the dyeing and finishing auxiliary agent in the liquid storage tank 2 is higher than the liquid level in the atomizer 5, so as to compare with the liquid level in the at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com