Large-displacement oil-water separator for gas holder

An oil-water separator and drainage technology, which are applied in liquid separation, separation methods, gas/liquid distribution and storage, etc., can solve the problems of wasting water and lowering the calorific value of gas, saving cooling water, increasing the calorific value of gas, Low cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

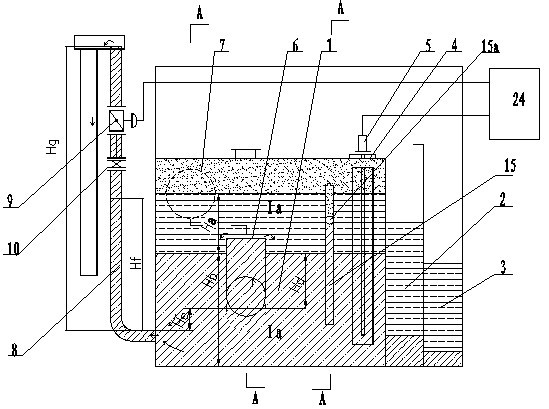

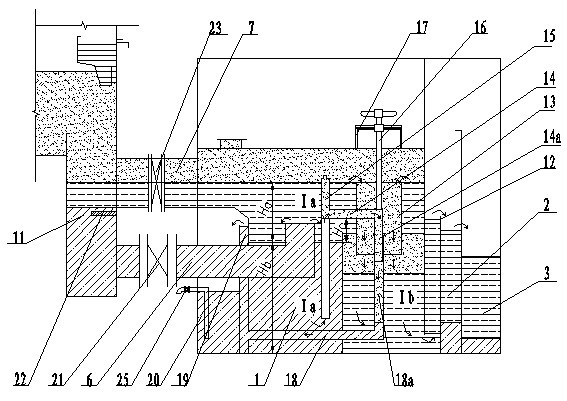

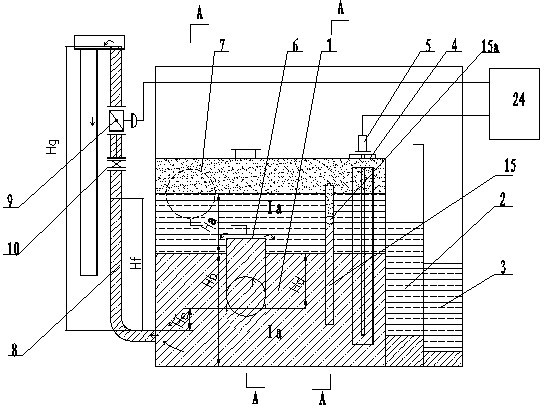

[0020] figure 1 It is a structural schematic diagram of the present invention, figure 2 for figure 1 A cross-sectional view along the direction of A-A-A-A, as shown in the figure: the large displacement oil-water separator of the gas cabinet in this embodiment includes a sealed separation chamber 1, a secondary separation chamber 2 and a recovery chamber 3, and the sealed separation chamber 1 communicates with the oil ditch 11 at the bottom of the gas cabinet , as shown in the figure, communicated through the connecting pipe 7 with valve 23; the sealed separation chamber 1 is divided into an oil-gas-water zone Ia and an oil-gas zone Ib through an overflow device, and the oil-gas zone Ib is located at the lower part of its oil level and the secondary separation chamber 2 are communicated, and the secondary separation chamber 2 is communicated with the recovery chamber 3, which can be communicated through a communication hole, a communication pipe or an overflow; it also inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com