Hip joint testing machine based on steel rope drive

A wire rope and hip joint technology, which is applied in the field of artificial joint testing machines, can solve problems such as large differences in hip joint motion, achieve the effects of reducing test costs and maintenance costs, increasing applicability, and preventing leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the embodiment in the accompanying drawings:

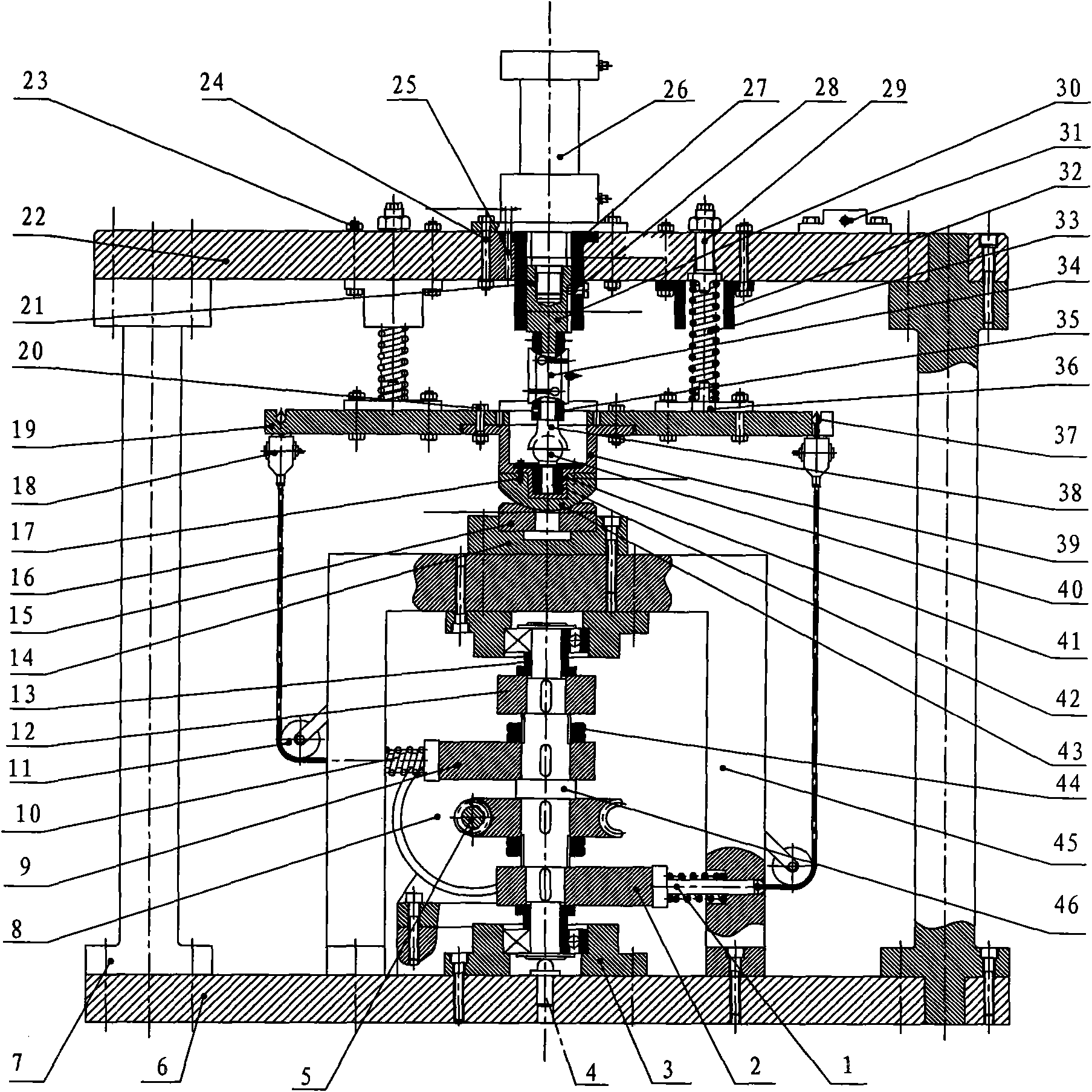

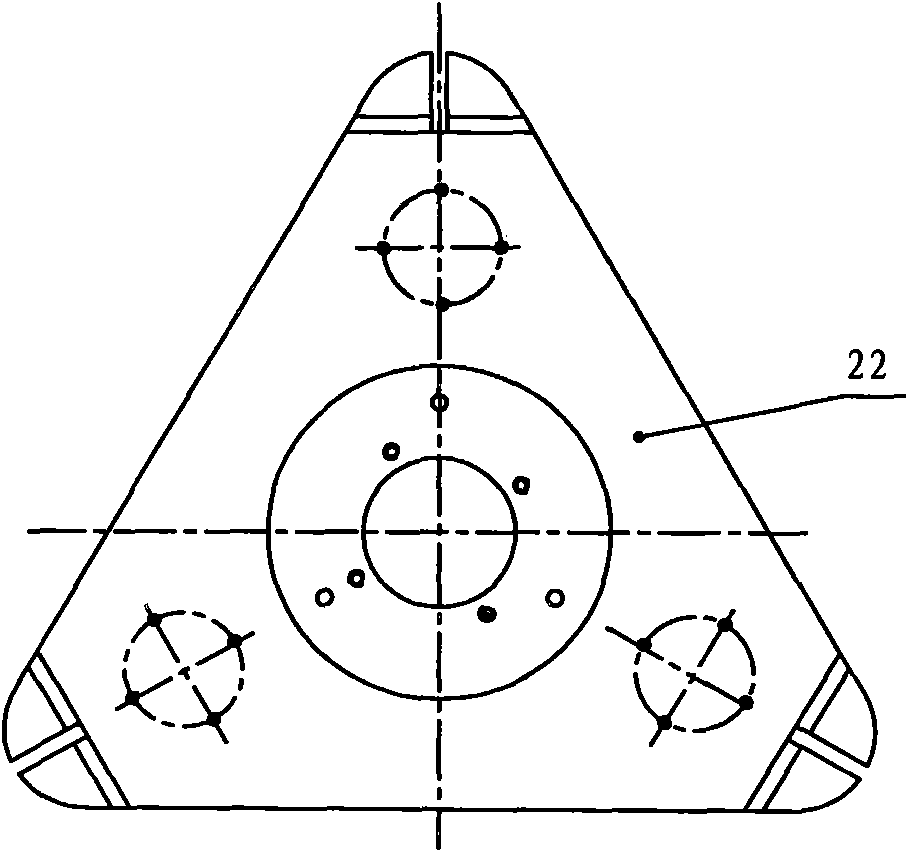

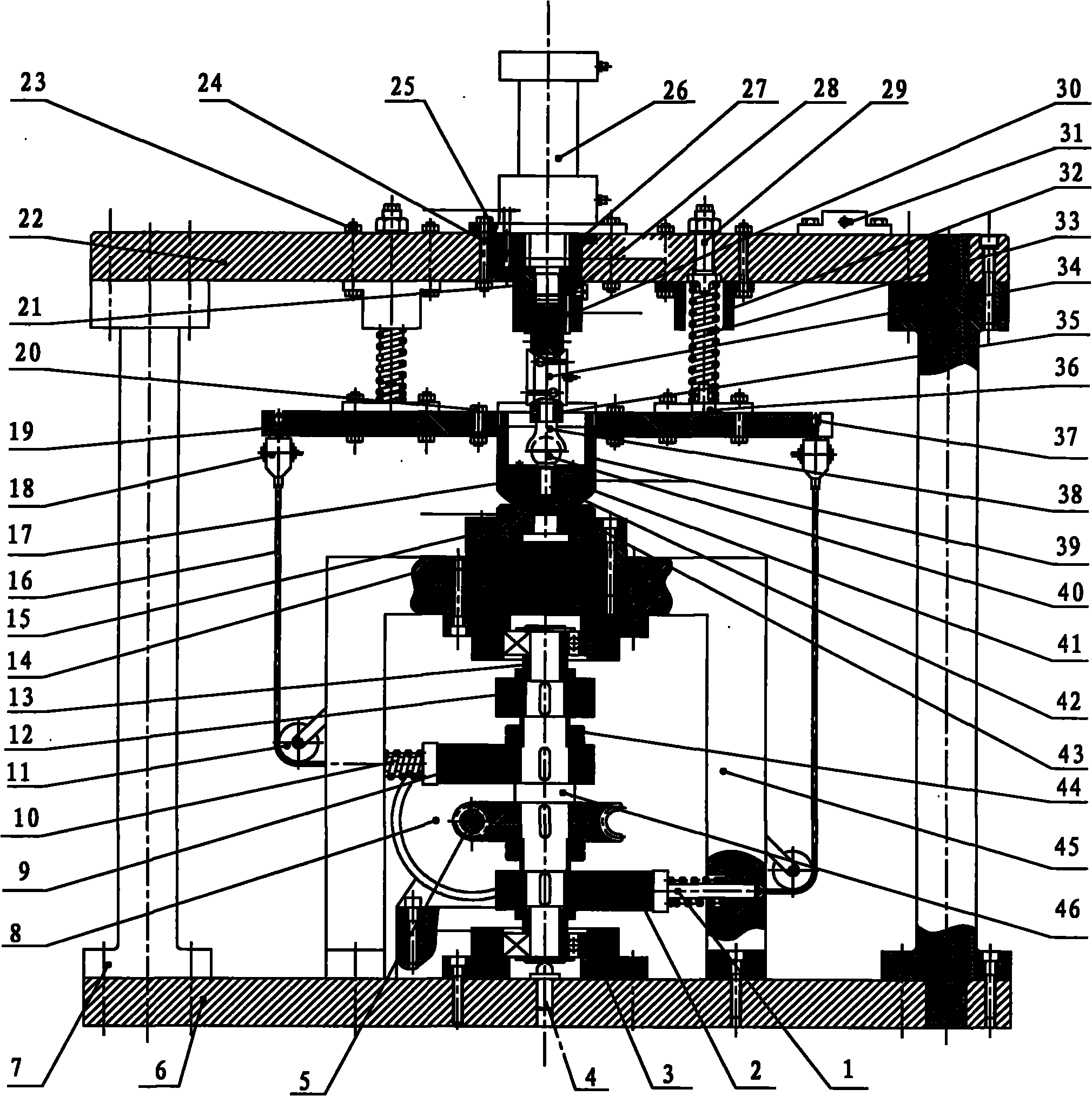

[0012] figure 1As shown, the hip joint testing machine based on the wire rope transmission mainly consists of a frame, a moving platform 19 located in the frame, a drive shaft 46, a cam, a worm gear transmission mechanism, a support frame 45, a solution basin 39, and a ball under the moving platform 19. Headstock 41, column type pressure sensor 34 above moving platform 19, guide block 30, hydraulic cylinder 26, spring device constitute, frame is made of top plate 22, base plate 6 and the pillar 7 that is connected between top and base plate. The worm gear transmission mechanism mainly consists of a stepper motor 8 and a worm gear 5 connected to the stepper motor 8. The support frame 45 is fixed on the base plate 6 of the frame, and the support frame 45 is provided with a vertical transmission shaft 46. The lower cam 2, the worm gear 5, the middle ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com