Photoetching device and photoetching method

A technology of lithography and detection devices, which is applied in the field of immersion lithography devices and lithography, and can solve problems such as lack of immediacy and prone to errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

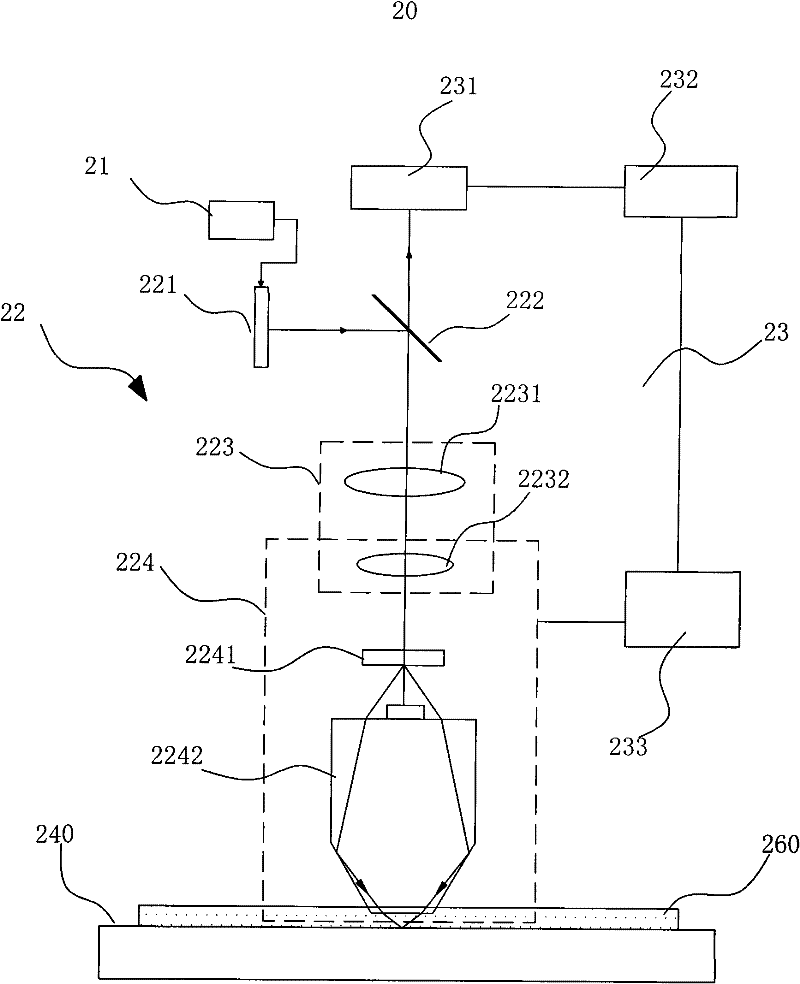

[0034] See figure 2 , figure 2 is a structural schematic diagram of the photolithography apparatus of the present invention. As shown in the figure, the lithography apparatus 20 includes an engraving light source 21 , an optical system 22 and an automatic focusing system 23 . The optical system 21 includes a diaphragm 221 , a partially reflective optical device 222 , an imaging lens group 223 and an interference optical head 224 . Wherein, the aperture 221 is a digital micromirror element or a spatial light modulator, which has an adjustable etching pattern. The imaging lens group 223 includes a first lens group 2231 and a second lens group 2232, the diaphragm 221 is positioned at the front focal plane of the first lens group 223, and the object surface 240 to be engraved is arranged at the back focus of the second lens group 2232 surface, in order to image the pattern formed on the aperture 221 onto the surface 240 of the object to be engraved with optimal resolution.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com