Special power battery management system for electric vehicle and implementation method thereof

A technology for power batteries and pure electric vehicles, which is applied in the field of lithium battery management systems for pure electric vehicles, can solve the problems of insufficient large-capacity series lithium battery packs, insufficient reliability, and single functions, etc., to improve energy utilization. , prolong battery life, and facilitate the effect of subsequent expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

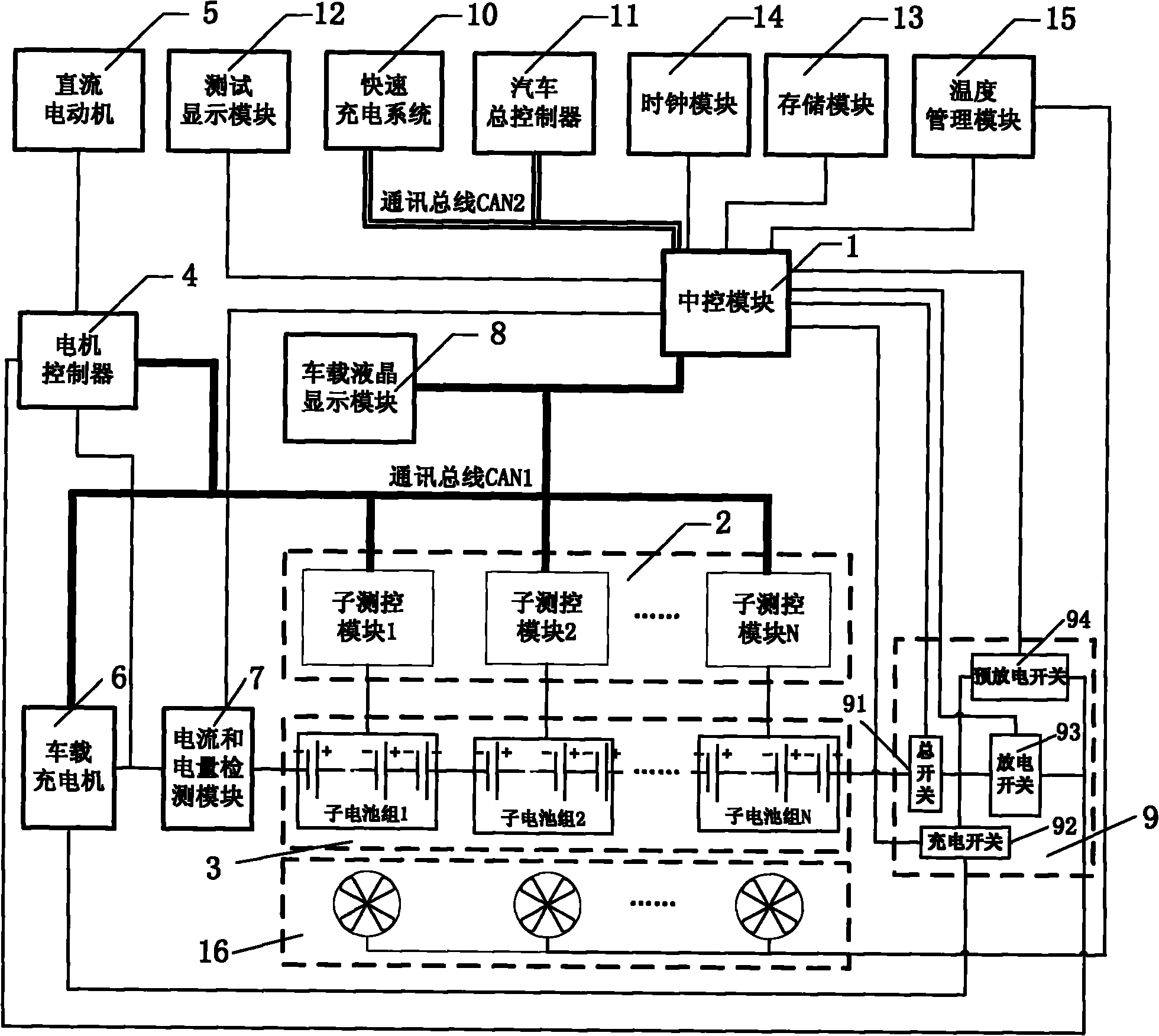

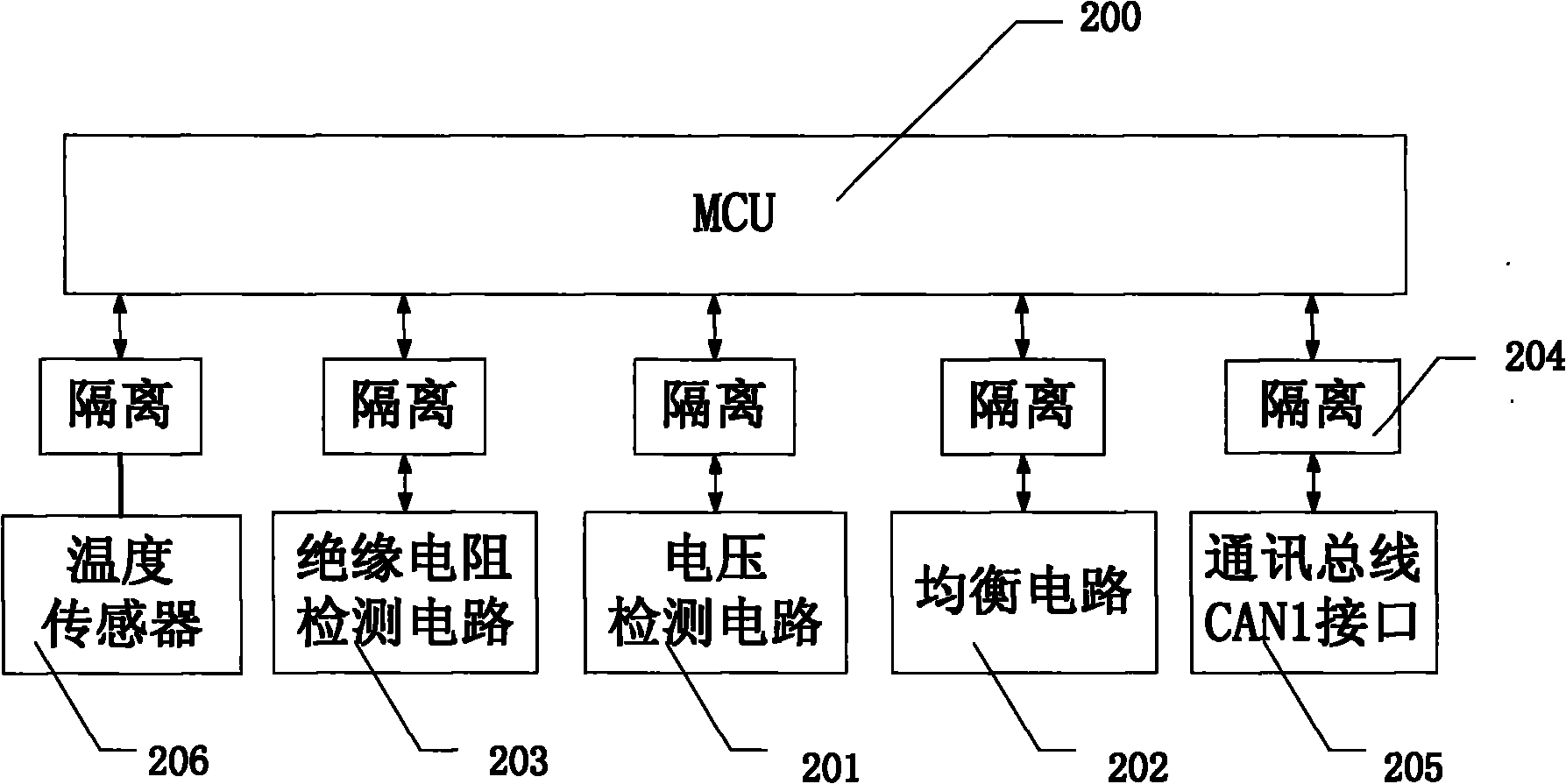

[0027] see figure 1 , a pure electric vehicle power battery management system, the system mainly includes a central control module 1, a measurement and control module 2, a battery pack 3, a motor controller 4, a DC motor 5, an on-board charger 6, a current and power detection module 7, and an on-board Liquid crystal display module 8, switch group 9, fast charging system 10, vehicle master controller 11, test display module 12, storage module 13, clock module 14, temperature management module 15. The system adopts a distributed structure, and only one communication bus CAN1 is needed to realize the communication between the central control module 1 and the measurement and control module 2, motor controller 4, vehicle charger 6, vehicle liquid crystal display module 8 and other equipment. Among them, each module is powered by a 12V power supply.

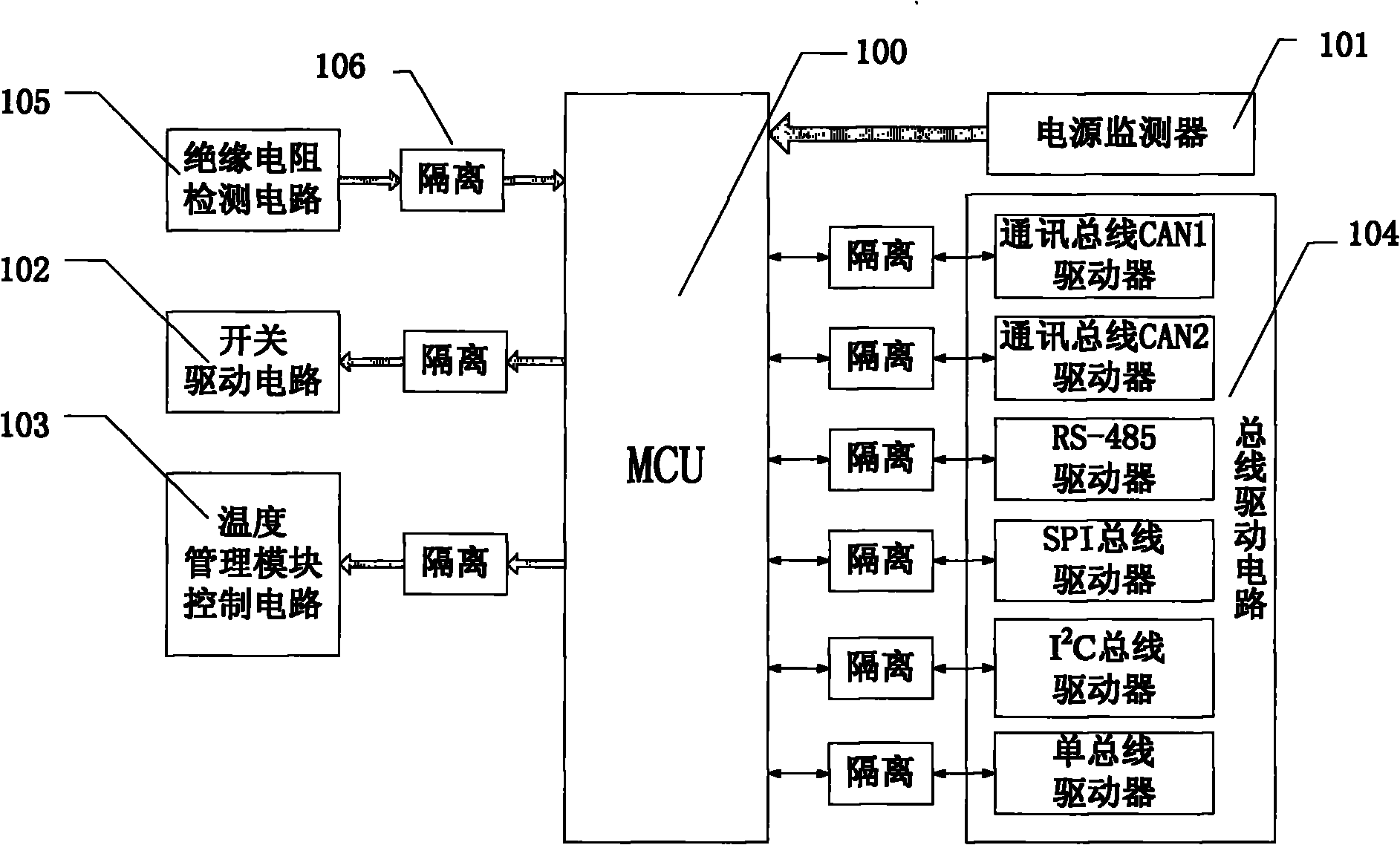

[0028] The central control module 1 is the core of the system to collect and control data information. On the one hand, the central...

Embodiment 2

[0044] The system structure of embodiment 2 is basically the same as that of the above embodiment 1, the difference is that in embodiment 2, the system also includes another communication bus CAN2, which is used for the central control module 1 and the fast charging system 10, the vehicle master controller 11 and other extended equipment communication, please refer to figure 1 . The fast charging system 10 is mainly to cooperate with the electric vehicle charging station under construction ( figure 1 not shown). The vehicle general controller 11 and the central control module 1 realize the coordinated work of the electric vehicle through data exchange. In addition, the central control module 1 is also equipped with an RS-485 bus interface connected to the test display module 12, which is used for the test management system during testing or failure.

[0045] The working state of the battery management system according to Embodiment 1 of the present invention will be describ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com