Method for producing modified white carbon black

A production method and technology of silica, applied in chemical instruments and methods, inorganic pigment treatment, dyed organosilicon compound treatment, etc., can solve the problems of pH accuracy drop, silica structure difference, and inability to truly reflect, etc., to achieve The effect of low modifier quota, high modification quota, and improved equipment utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

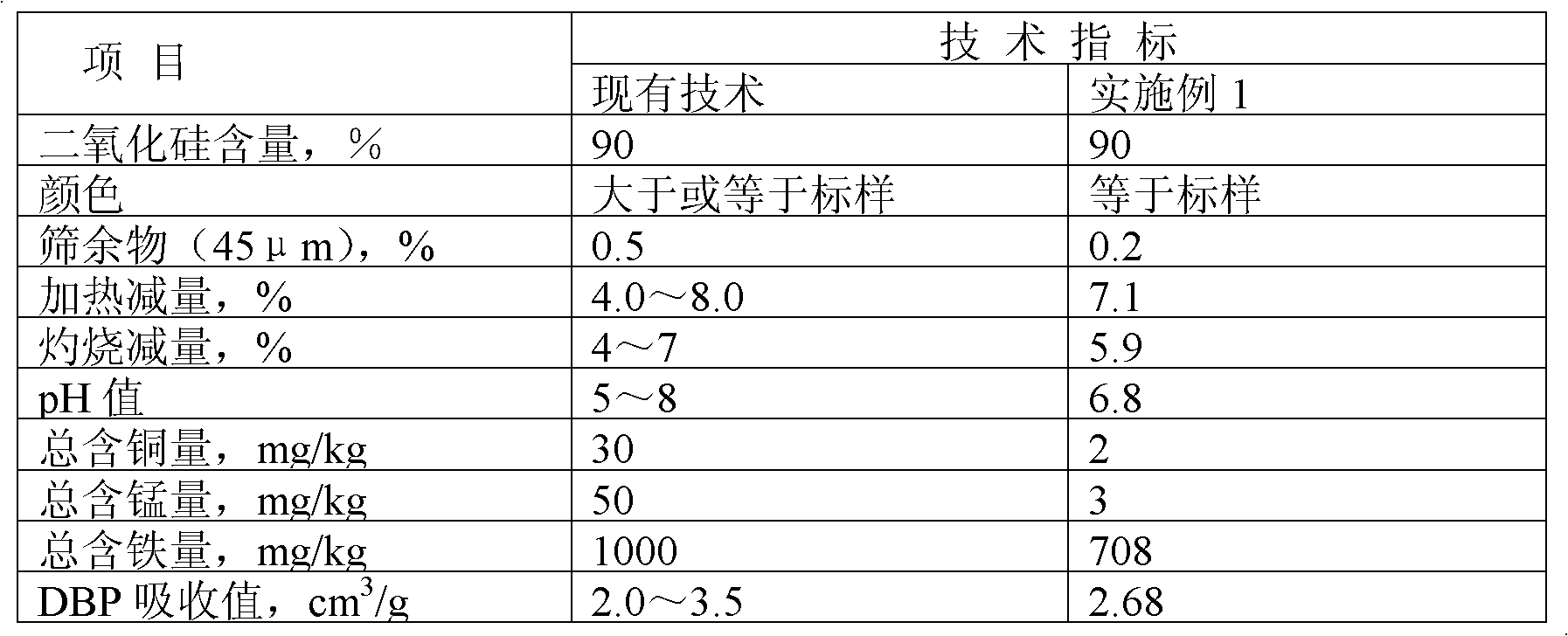

Embodiment 1

[0041] A kind of production method of modified white carbon black, comprises the following steps successively:

[0042] Water glass refining: the refining method is to add the purchased solid water glass to water in a mass ratio of 1:1.8 into a pressure vessel, pass in superheated steam with a pressure of 0.6Mpa to dissolve, discharge the material into a sedimentation tank, settle for 30 hours, and use a box press Filter through a filter, get its transparent clear liquid, and reserve it for production;

[0043] Dosing modification reaction: first meter 600Kg of clarified water glass and 5400kg of water and 6Kg of sodium chloride dispersant at 25 degrees Baume into the reactor to create an alkaline environment for reaction, then start the mixer and heat it with steam. When reaching the preset temperature of 82°C, add 98% concentrated sulfuric acid and water glass of 25 degrees Baume dropwise to the reactor at the same time, control the precise addition of concentrated sulfuric ...

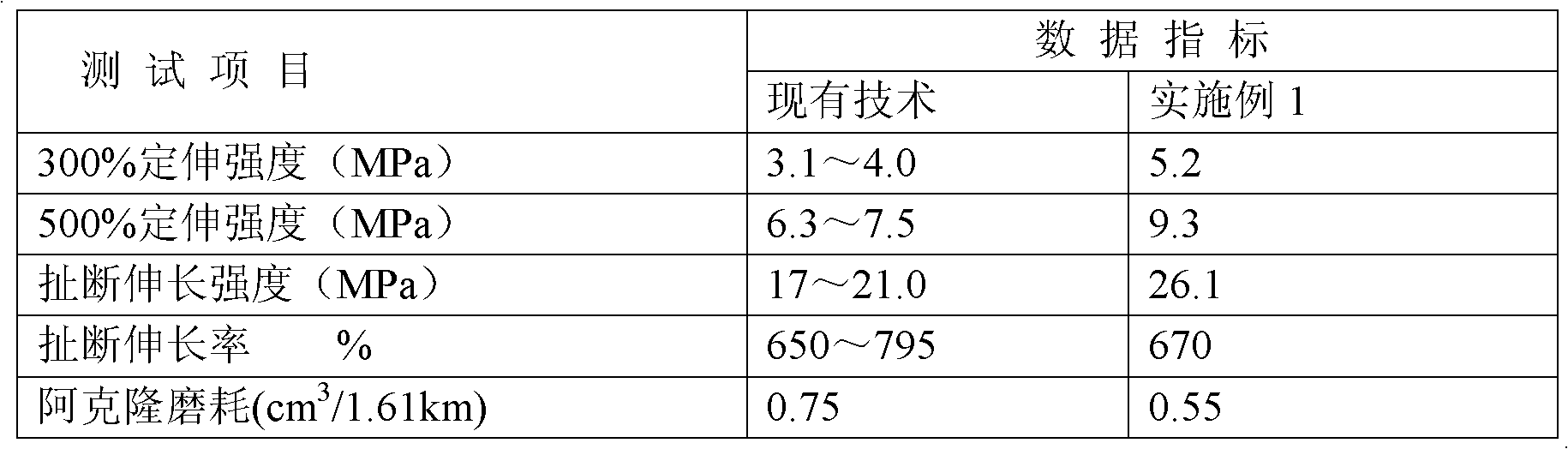

Embodiment 2

[0053] A kind of production method of modified white carbon black, comprises the following steps successively:

[0054] Water glass refining: the refining method is to add the purchased solid water glass to water in a mass ratio of 1:1.5 into a pressure vessel, pass in superheated steam with a pressure of 0.5Mpa to dissolve, discharge the material into the sedimentation tank, settle for 24 hours, and use a box press Filter through a filter, get its transparent clear liquid, and reserve it for production;

[0055] Liquid modification reaction: First, add 630Kg of clear water glass of 30 Baume degrees, 5460kg of water, and 8Kg of sodium chloride dispersant to the reaction kettle to create an alkaline environment for reaction, then start the mixer and feed in steam for heating , when the predetermined temperature reaches 75°C, add 98% concentrated sulfuric acid and water glass of 28 degrees Baume dropwise to the reactor at the same time, and control the precise addition of concen...

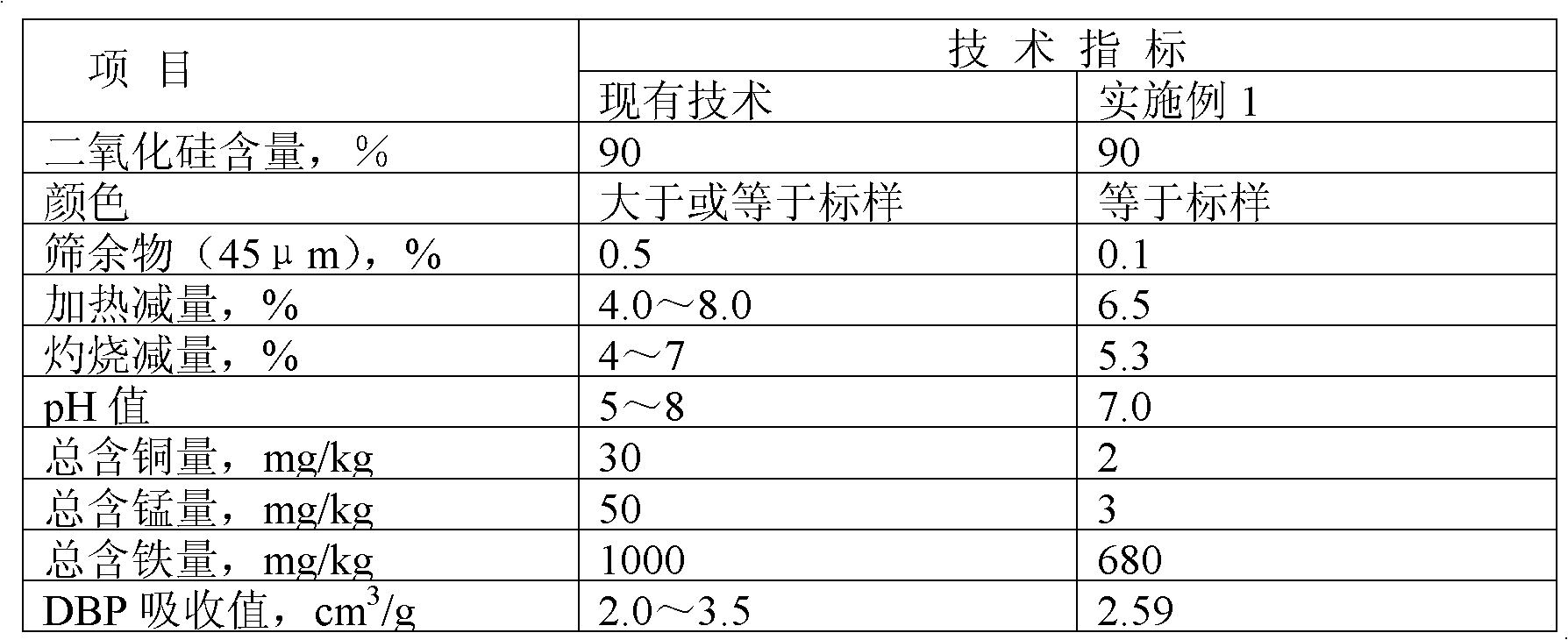

Embodiment 3

[0065] A kind of production method of modified white carbon black, comprises the following steps successively:

[0066] Water glass refining: The refining method is to add the purchased solid water glass to water in a mass ratio of 1:2.0 into a pressure vessel, pass in superheated steam with a pressure of 0.55Mpa to dissolve, discharge the material into the sedimentation tank, settle for 36 hours, and use a box press Filter through a filter, get its transparent clear liquid, and reserve it for production;

[0067] Dosing modification reaction: First, add 660Kg of clarified water glass and 4920kg of water and 6.6Kg of sodium sulfate dispersant to the reaction kettle to create an alkaline environment for the reaction, then start the mixer and heat, when it reaches When the predetermined temperature is 75°C, add 98% concentrated sulfuric acid and water glass of 30 Baume degrees dropwise to the reactor at the same time, control the precise addition of concentrated sulfuric acid an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com