Method for producing ethanol by fermenting raw thick mash at low temperature

A technology of thick mash fermentation and ethanol, applied in the direction of microorganism-based methods, biochemical equipment and methods, fermentation, etc., can solve the problems of time and energy consumption, reduce production costs, etc., save the cooking process, reduce the amount of steam, Avoid the effects of substrate inhibition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

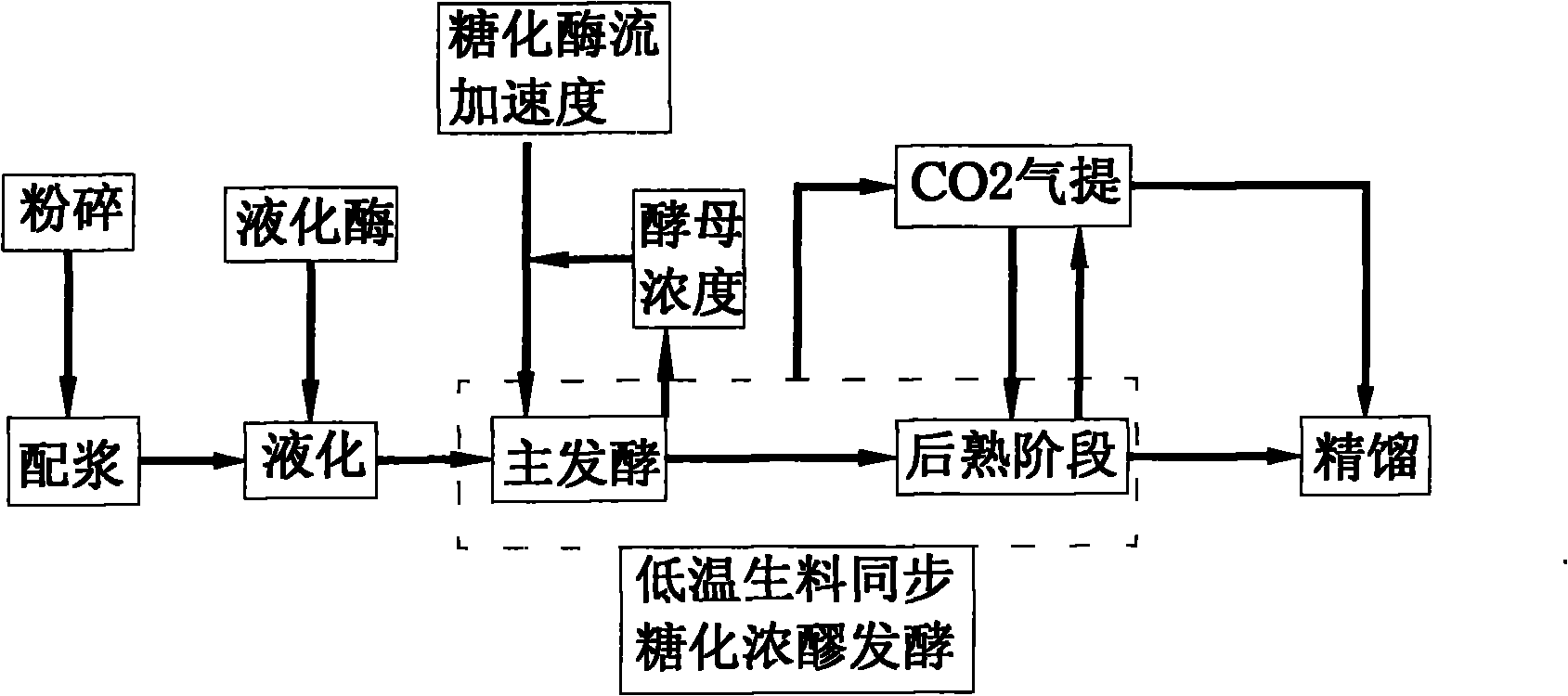

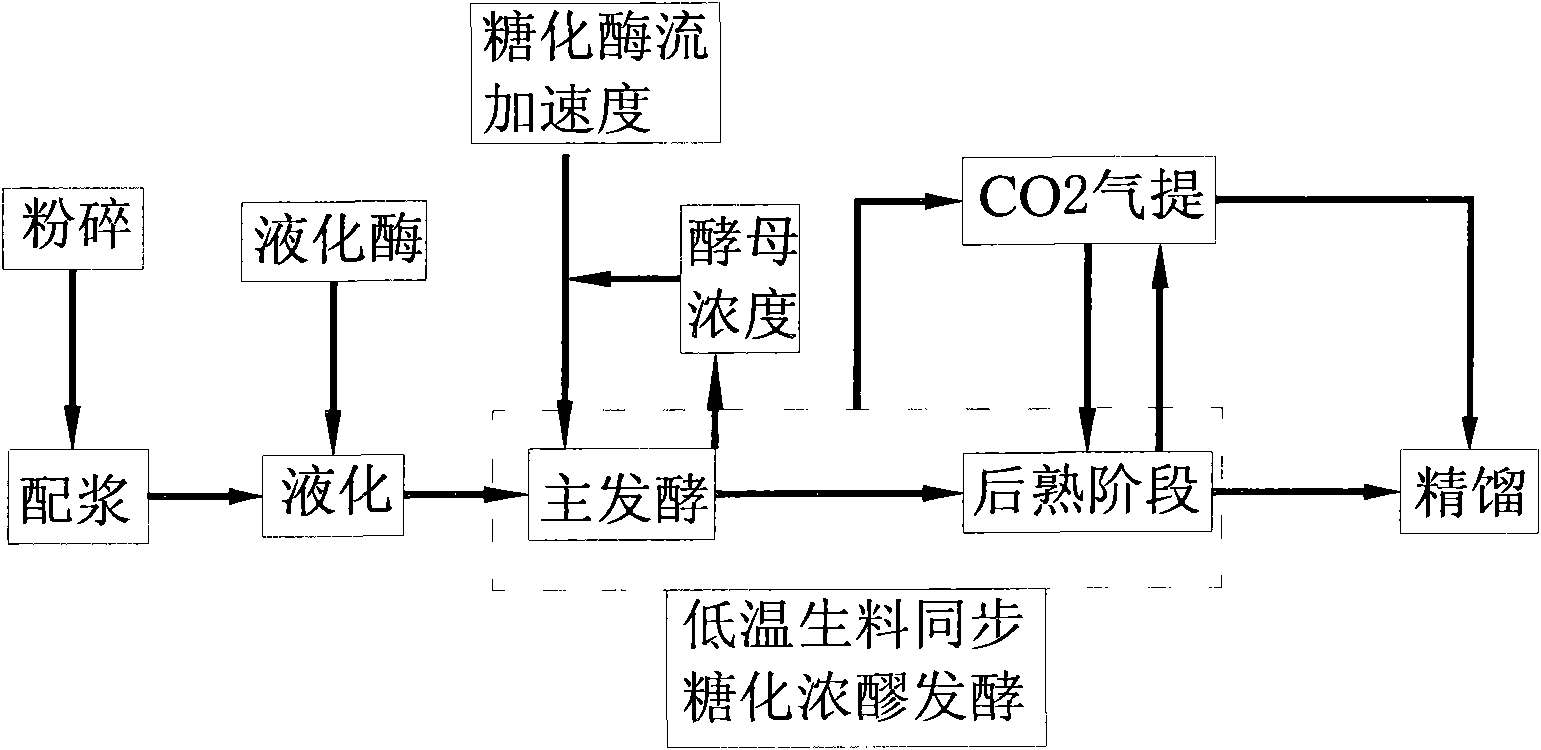

[0023] According to the process route figure 1 As shown, carry out low-temperature raw material dense mash fermentation to produce ethanol, the specific steps are as follows:

[0024] 1. Utilize dried cassava flakes as a raw material, after the dried cassava flakes are pulverized, calculate with process water by weight, add 1.7 parts of process water to 1 part of cassava dry flakes for batching, and obtain a powder slurry with a mass concentration of 33.3%;

[0025] 2. The above-mentioned slurry is heated to 80° C., calculated by the weight of the dried cassava slices, and 50 units of amylase is added to each gram of the dried cassava slices to carry out low-temperature liquefaction treatment, wherein the liquefaction temperature is 80° C. and the time is 45 minutes;

[0026] 3. Cool the mash after the above-mentioned liquefaction treatment to normal temperature (28° C.), add 100 units of glucoamylase per gram of cassava dry flakes, and insert it into brewer's yeast (Saccharom...

Embodiment 2

[0034] According to the process route figure 1 As shown, carry out low-temperature raw material dense mash fermentation to produce ethanol, the specific steps are as follows:

[0035] 1. Using fresh cassava as raw material, cassava is pulverized, and process water is calculated by weight, 1 part of fresh cassava is added to 1.7 parts of process water for batching, and a powder slurry with a mass concentration of 30% is obtained;

[0036] 2. The above-mentioned slurry is heated to 75°C, calculated according to the weight of the dried cassava slices, and 30 units of amylase is added to each gram of the dried cassava slices to carry out low-temperature liquefaction treatment, wherein the liquefaction temperature is 75°C and the time is 60 minutes;

[0037] 3. Cool the mash after the above-mentioned liquefaction treatment to normal temperature (30° C.), calculate by the weight of cassava dry slices, add 80 units of glucoamylase per gram of cassava dry slices, insert brewing yeast ...

Embodiment 3

[0045] According to the process route figure 1 As shown, carry out low-temperature raw material dense mash fermentation to produce ethanol, the specific steps are as follows:

[0046] 1. Using fresh cassava as raw material, cassava is pulverized, and process water is calculated by weight, 1 part of fresh cassava is added to 1.7 parts of process water for batching, and a powder slurry with a mass concentration of 30% is obtained;

[0047] 2. The above-mentioned slurry is heated to 70°C, calculated according to the weight of the dried cassava slices, and 30 units of amylase is added to each gram of the dried cassava slices to carry out low-temperature liquefaction treatment, wherein the liquefaction temperature is 70°C and the time is 30 minutes;

[0048] 3. Cool the mash after the above-mentioned liquefaction treatment to normal temperature (32° C.), calculate by the weight of cassava dry slices, add 120 units of glucoamylase per gram of cassava dry slices, insert brewer’s yeas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com