Method for producing ethanol by fermenting raw thick mash at low temperature

A technology for concentrated mash fermentation and ethanol, which is applied in the directions of microorganism-based methods, biochemical equipment and methods, fermentation, etc., can solve the problems of time-consuming and energy-consuming, reduce production costs, etc. Guaranteed rapid growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

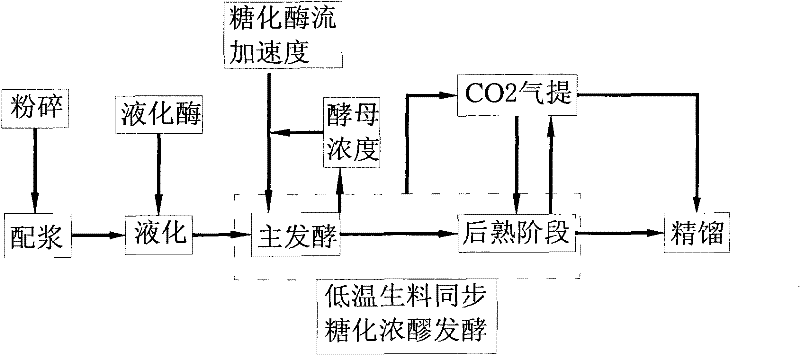

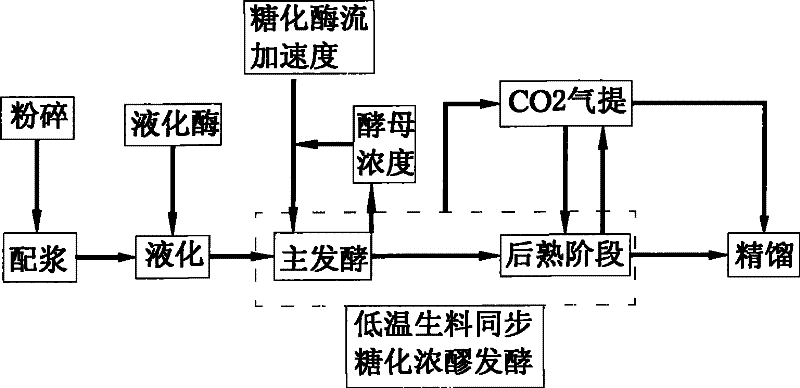

[0023] By process route figure 1 As shown, the low-temperature raw material thick mash fermentation to produce ethanol, the specific steps are as follows:

[0024] 1. Using dried cassava slices as raw materials, the dried cassava slices are crushed and calculated by weight with process water. 1 part of dried cassava slices is mixed with 1.7 parts of process water to obtain a slurry with a mass concentration of 33.3%;

[0025] 2. Heat the above-mentioned slurry to 80°C, calculate according to the weight of the dried cassava slices, add 50 units of amylase per gram of dried cassava slices to carry out low-temperature liquefaction treatment, wherein the liquefaction temperature is 80°C and the time is 45 minutes;

[0026] 3. Cool the mash after the above liquefaction treatment to normal temperature (28℃), calculate according to the weight of dried cassava slices, add 100 units of glucoamylase per gram of dried cassava slices, and access to brewing yeast (Saccharomyces cerevisiae, No. 2)...

Embodiment 2

[0034] By process route figure 1 As shown, the low-temperature raw material thick mash fermentation to produce ethanol, the specific steps are as follows:

[0035] 1. Using fresh cassava as the raw material, the cassava is crushed and calculated by weight with process water. 1 part of fresh cassava is mixed with 1.7 parts of process water to obtain a slurry with a mass concentration of 30%;

[0036] 2. Heat the above-mentioned slurry to 75°C, calculate according to the weight of the dried cassava slices, add 30 units of amylase per gram of dried cassava slices to carry out low-temperature liquefaction treatment, where the liquefaction temperature is 75°C and the time is 60 minutes;

[0037] 3. Cool the mash after the above liquefaction treatment to normal temperature (30℃), calculate according to the weight of dried cassava slices, add 80 units of glucoamylase per gram of dried cassava slices, and access to brewing yeast (Saccharomyces cerevisiae, No. 2) , Purchased from an alcohol ...

Embodiment 3

[0045] By process route figure 1 As shown, the low-temperature raw meal concentrated mash fermentation to produce ethanol, the specific steps are as follows:

[0046] 1. Using fresh cassava as the raw material, the cassava is crushed and calculated by weight with process water. 1 part of fresh cassava is mixed with 1.7 parts of process water to obtain a slurry with a mass concentration of 30%;

[0047] 2. Heat the above-mentioned slurry to 70°C, calculate according to the weight of the dried cassava slices, add 30 units of amylase per gram of dried cassava slices to carry out low-temperature liquefaction treatment, where the liquefaction temperature is 70°C and the time is 30 minutes;

[0048] 3. Cool the mash after the above liquefaction treatment to normal temperature (32°C), calculate according to the weight of dried cassava slices, add 120 units of glucoamylase per gram of dried cassava slices, and access to brewing yeast (Saccharomyces cerevisiae, No. 2) , Purchased from an alc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com