Analysis evaporator

An evaporator and flow path technology, applied in the field of analytical evaporators, can solve the problems of poor control of flow velocity and flow process, certain safety of operators, splashing or overflow of low-temperature liquid, etc., and achieves strong controllable performance and convenient operation , light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

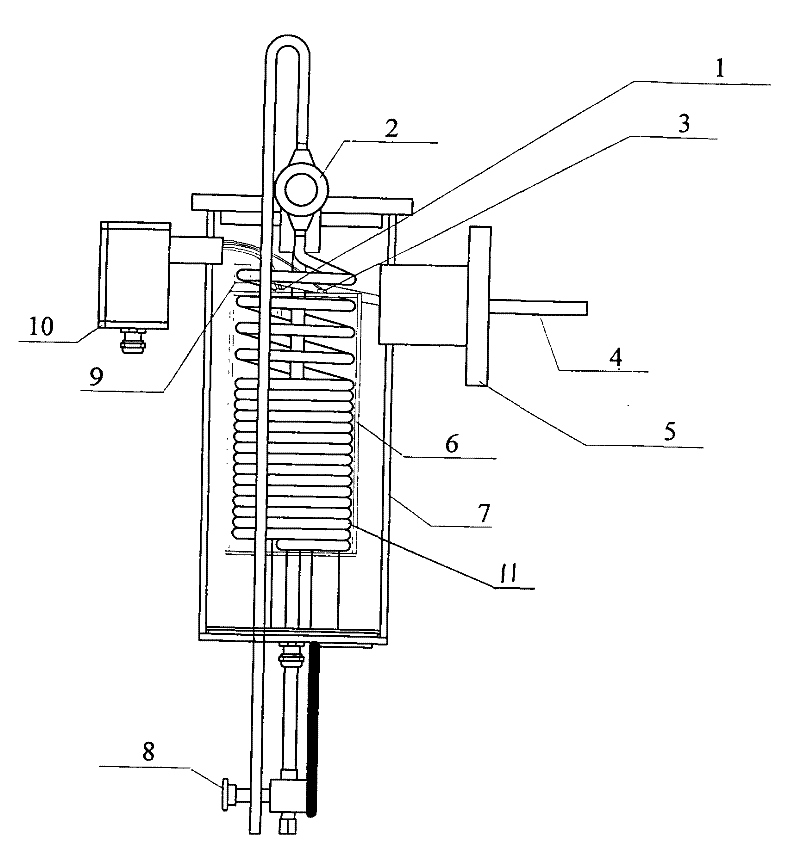

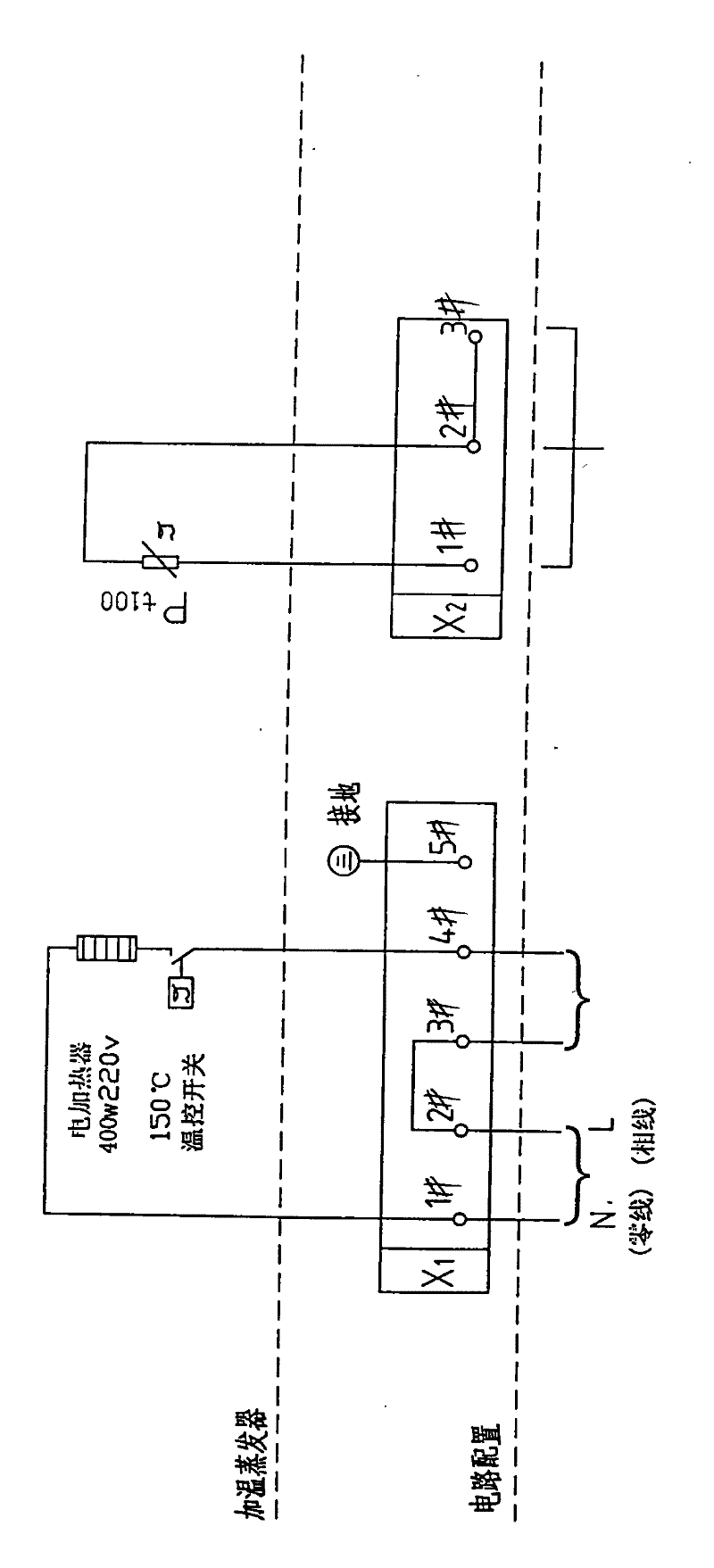

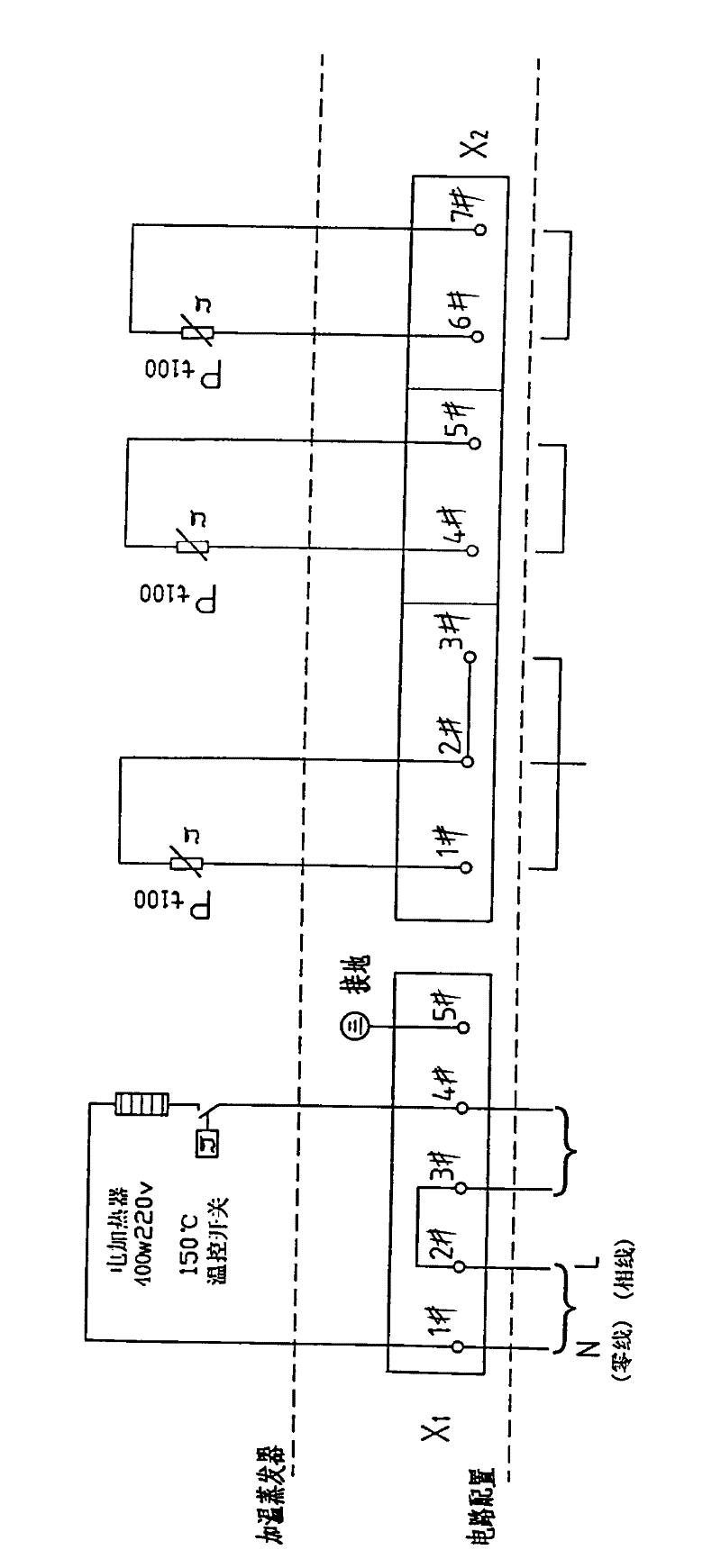

[0011] Control attached figure 1 , which is characterized by an overall structure, with a heating flow path body 6 inside, a Pt100 platinum resistance 1 inserted in the heating flow path body 6, one end of the heating wire 3 is connected in series with the temperature switch K, and the other end of the heating wire is connected to the power supply The terminal X1 is connected; the signal line of the Pt100 platinum resistance is connected to the control signal connection terminal X2; the outer shell 7 is a cylindrical container body, connected to the flange 4, the air inlet connecting pipe 4, the gas output valve 8, the exhaust end valve 2 and The external power supply and signal line are fixed on the shell with junction box 10 .

[0012] The main body 6 of the heating flow path is aluminum cylindrical, and the innermost layer of the main body of the heating flow path is an aluminum cylindrical heating element with an embedded electric heating wire. The long coil 11 is covered ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com