Low-loss stationary-phase coaxial radio-frequency cable and manufacturing process thereof

A radio frequency cable, low-loss technology, used in circuits, electrical components, waveguides, etc., can solve the problems of large loss, large phase change, and low frequency of use of the cable, and achieve the purpose of reducing attenuation, offsetting phase change rate, and improving stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

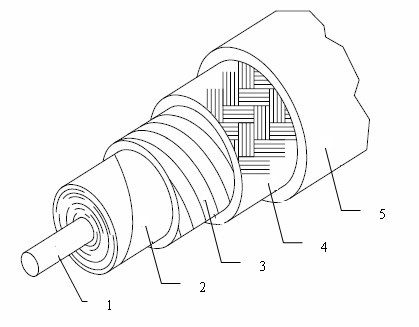

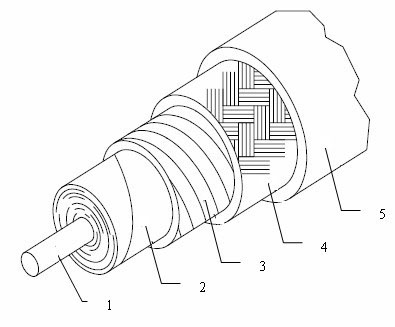

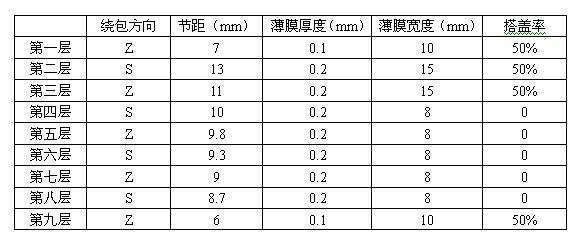

[0015] Such as figure 1 As shown, a low-loss stable coaxial radio frequency cable has several layers of microporous polytetrafluoroethylene film insulation layers 2 wrapped around the silver-plated copper alloy core 1, and several layers of microporous polytetrafluoroethylene film insulation layers 2 Silver-plated copper flat tape inner shield 3 is wrapped around the outside, a layer of silver-plated copper outer conductor 4 is braided outside the silver-plated copper flat tape inner shield 3, and a layer of polyfluoroethylene propylene is extruded outside the silver-plated copper outer conductor 4. Set of 5. Several layers of microporous polytetrafluoro film insulating layers 2 are nine layers.

[0016] A low-loss stable coaxial radio frequency cable manufacturing process, the cable manufacturing process steps are as follows:

[0017] ①, silver-plated copper alloy wire core inner conductor 1: the diameter is 2.30±0.03mm, the thickness of the silver layer is 4.5μm, and the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com