Device for directly electrifying and heating steel belt by using molten metal electrode

A heating device and molten metal technology, applied in ohmic resistance heating parts, ohmic resistance electrodes, heat treatment furnaces, etc., can solve problems such as easy generation of electric sparks, complex electrode structure, and difficult manufacturing, and achieve good contact and electrical conductivity Excellent, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

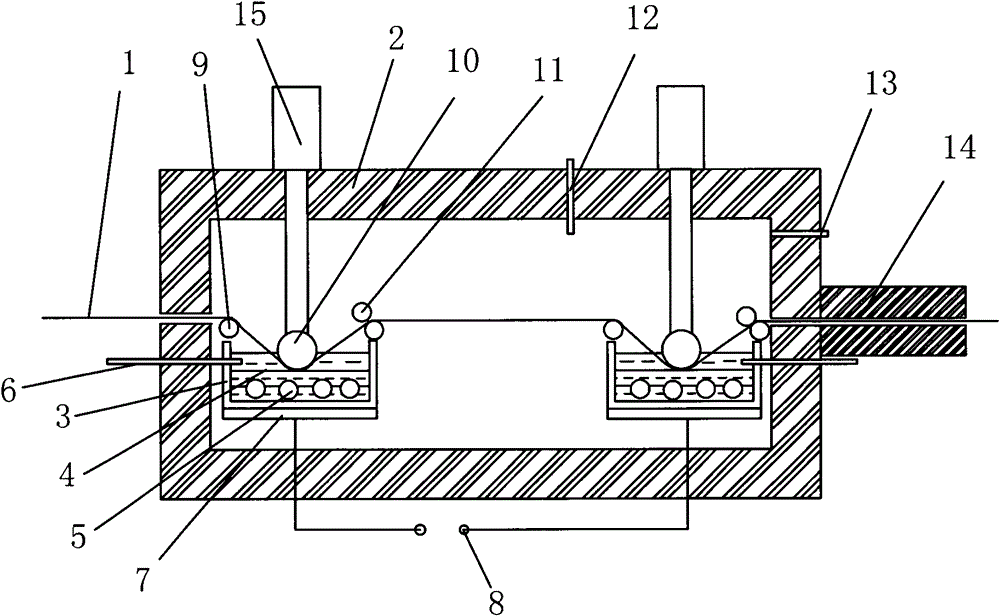

[0016] Such as figure 1 As shown, a steel strip heating device for a metal liquid electrode directly energizes, including a heat-insulating metal box 2, a steel strip 1 passing through the heat-insulating metal box 2, and two metal strips corresponding to the steel strip 1 are arranged in the heat-insulating metal box 2. A liquid metal tank 3, the liquid metal layer 4 corresponding to the steel strip 1 is arranged in the liquid metal tank 3, and the two liquid metal tanks 3 are respectively connected with the secondary electrodes 8 of the transformer. An electric heating rod 5 corresponding to the molten metal layer 4 is provided in the molten metal tank 3 . The heat-retaining metal box 2 is provided with a thermocouple 6 in contact with the molten metal layer 4 . The bottom of the molten metal tank 3 is provided with a copper plate 7 connected to the secondary electrode 8 of the transformer. A turning roller 9 corresponding to the steel strip 1 is provided on both sides of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com