Device for continuously concentrating gelatin by membrane technology

A concentrating device and gelatin technology, which are applied in the field of membrane continuous gelatin concentrating devices, can solve the problems of low freezing force and viscosity, large ash content and high energy consumption of products, and achieve easy self-control and maintenance, reduced yield and low power consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

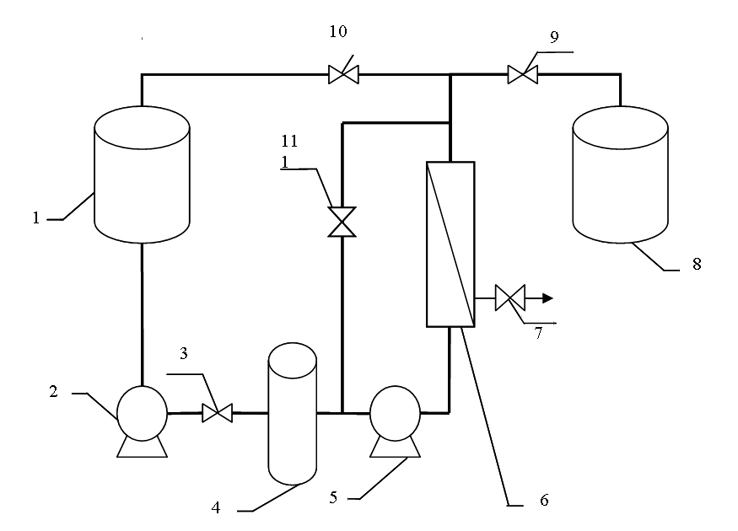

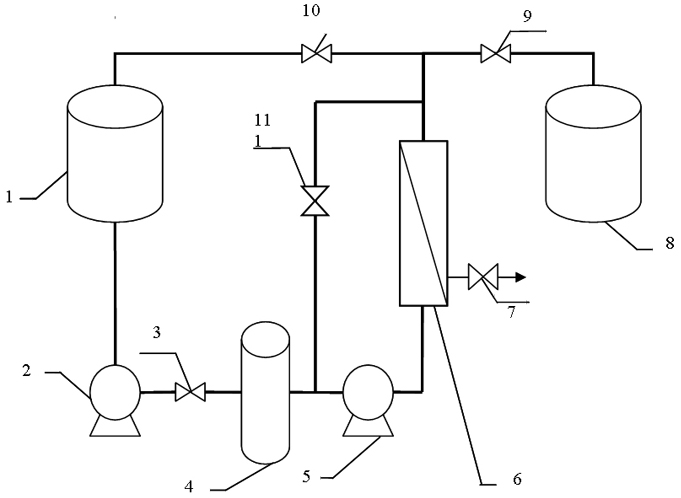

[0020] See figure 1 A continuous gelatin concentration device by membrane method includes a roll-type membrane module 6 composed of a plurality of roll-type ultrafiltration membranes combined in series and parallel, and the molecular weight cut-off of the ultrafiltration membrane is 5000-10000MW.

[0021] The outlet of the roll membrane module 6 is connected to the first port of the four-way joint. The second and third ports of the four-way joint are connected to the raw glue tank 1 and the thick glue tank 8 respectively; the inlet of the roll membrane module 6 is connected to The outlet of the circulating pump 5; the suction pump 2 and the filter 4 are connected in series between the raw rubber tank 1 and the inlet of the circulating pump 5; the first shut-off valve 3 is connected in series between the suction pump 2 and the filter 4 ; The pipe between the original glue tank 1 and the outlet of the roll membrane module 6 is connected in series with a second stop valve 10; the pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com