Annular speed reducer

A reducer and ring-type technology, which is applied in the direction of transmission parts, gear transmissions, and components with teeth, etc., can solve the problems of uneven load on the ring plate, small, only within 100, and unbalanced motion. , to achieve the effect of improving internal lubrication, easy manufacturing and low cost, and widely popularized value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings.

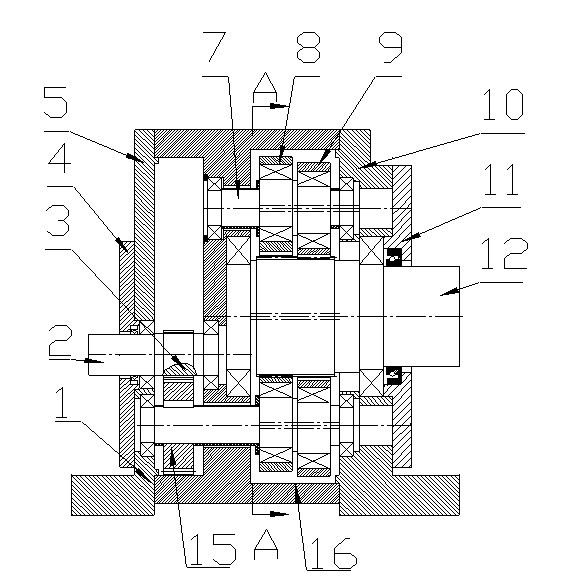

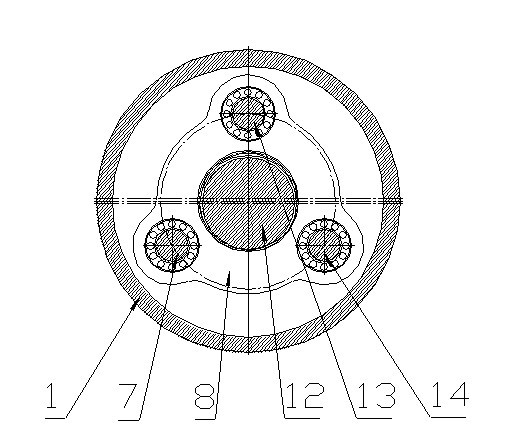

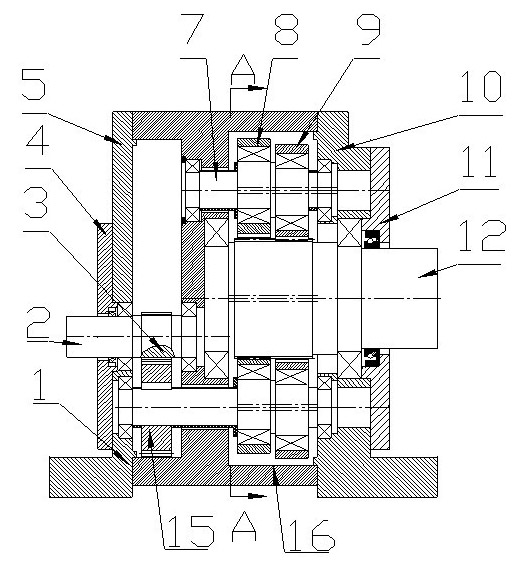

[0021] see figure 1 , figure 2 Schematic diagram of the structure of the present invention, the ring-type reducer of the present invention includes a reducer casing 1 and an input shaft 2, a driving gear 3 is installed on the input shaft 2, and the input shaft 2 drives the driving gear 3 to rotate synchronously; Inside the body 1, there are three eccentric shafts, i.e. the first eccentric shaft 7, the second eccentric shaft 13, and the third eccentric shaft 14. The axes of the three eccentric shafts are parallel to each other and arranged in an equilateral triangle; Or two, or three driven gears 15 are installed on the eccentric shafts, one or two or three driven gears 15 can mesh with the driving gear 3, and the driving gear 3 drives one, or two, or three eccentric shafts when rotating. The driven gear 15 installed on the sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com