Method for treating sewage by utilizing grid aeration tank

An aeration tank and sewage technology, which is applied in sustainable biological treatment, chemical instruments and methods, and multi-stage water/sewage treatment, etc., can solve the problems of low utilization rate of dissolved oxygen, high energy consumption for aeration, and save aeration. Energy consumption, improved oxygen transfer rate, high activity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

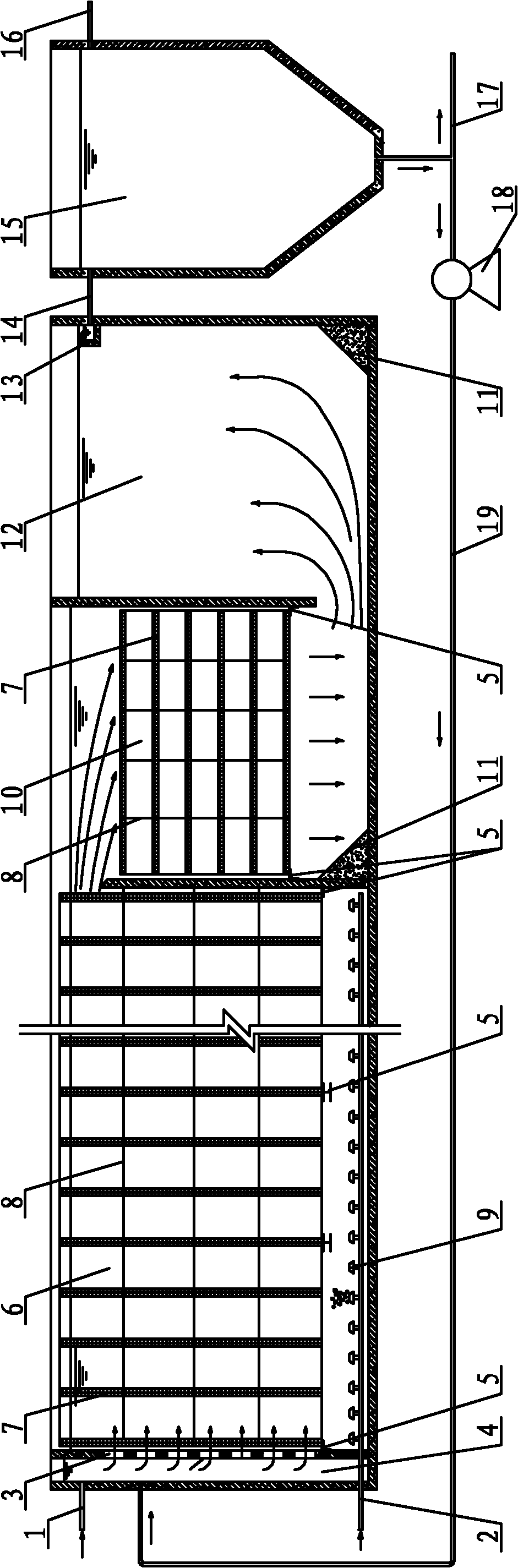

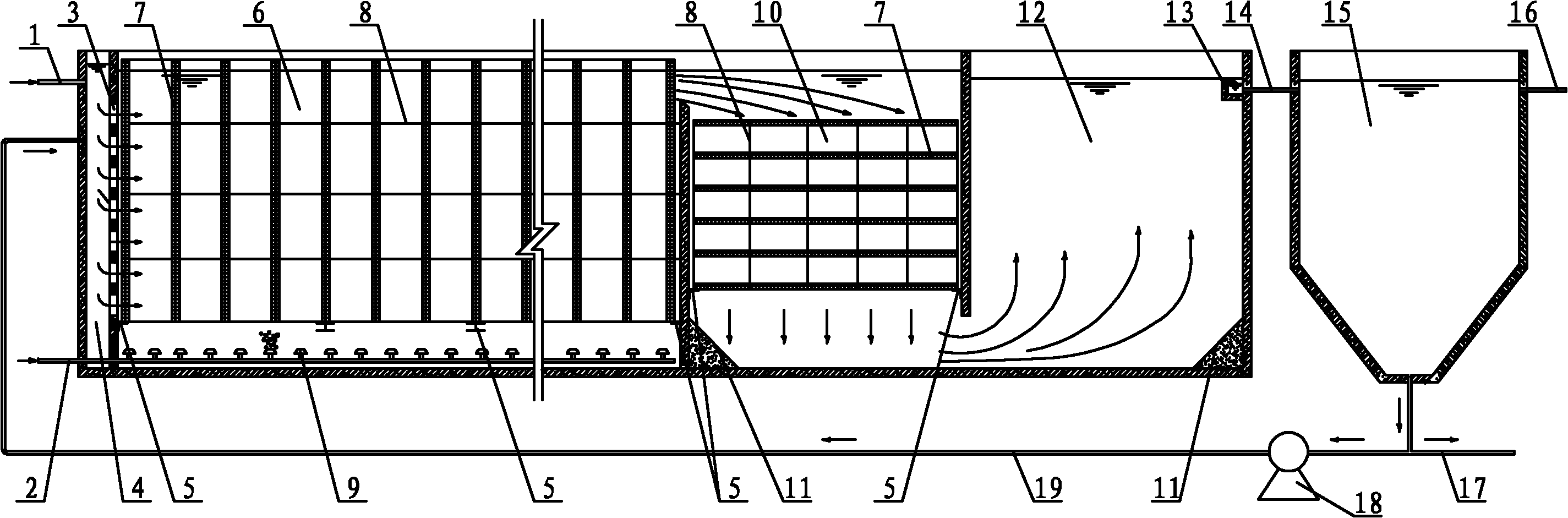

[0008] Specific implementation mode one: combine figure 1 Describe this embodiment, this embodiment is realized by following steps: Step 1, put into sewage: sewage flows into water distribution pool 4 by water inlet pipe 1, flows into the cross section of vortex biochemical pool 6 evenly through the water distribution hole 3 on the water distribution pool 4 On the surface, the flow velocity of the through hole is 0.08m / s~0.12m / s; step 2, aeration process: the sewage flows through the vertically placed multi-layered eddy current biochemical pool 6 under the action of the driving force and inertial force of the subsequent water flow. The grid 7 forms a horizontal flow. At this time, the activated sludge in the vortex biochemical tank 6 is in a suspended state, and the residence time of the sewage in the vortex biochemical tank 6 is 1.5h to 4.0h. The air diffused from the aeration head 9 is Gradually rise from the lower part to the surface of the water body, and the amount of air...

specific Embodiment approach 2

[0011] Specific implementation mode two: combination figure 1 To illustrate this embodiment, in the vertically placed multi-layer grid 7 in step 2 of this embodiment, the distance between two adjacent grids 7 is 0.5m to 1.0m, and the shape of each grid 7 is Circular, regular polygon or rectangular, the diameter of the inscribed circle of each grid 7 is controlled at 0.045m~0.065m. The mixed liquid can be mixed horizontally and vertically within this interval, which is beneficial to the redistribution of dissolved oxygen, organic substrate and activated sludge on the entire cross-section of the tank, avoiding aeration dead zones, and improving the utilization of the aeration head Rate. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0012] Specific implementation mode three: combination figure 1 To illustrate this embodiment, in the horizontally placed multi-layer grid 7 in step 3 of this embodiment, the distance between two adjacent grids 7 is 0.4m to 0.6m, and the shape of the hole of each grid 7 is a circle shape, regular polygon or rectangle, and the diameter of the inscribed circle of each grid 7 is controlled at 0.045m to 0.065m. The mixed liquid can be flocculated in this interval, which is beneficial to dissolved oxygen, organic substrate and activated sludge. Other steps are the same as in the first embodiment.

[0013] Specific implementation mode four: combination figure 1 To describe this embodiment, in Step 3 of this embodiment, a diversion slope 11 is provided at the bottom corner of the vortex flocculation tank 10 . The diversion slope 11 can be poured concrete or bricks twice, and the diversion slope 11 is to prevent the formation of sludge dead ends. Other steps are the same as in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com