Self-cleaning glass and preparation method thereof

A glass, self-cleaning technology, applied in chemical instruments and methods, glass/slag layered products, layered products, etc., can solve the problems of low photocatalytic efficiency of glass, low bonding force between layers and glass, etc. Efficiency, good bonding force, and the effect of improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

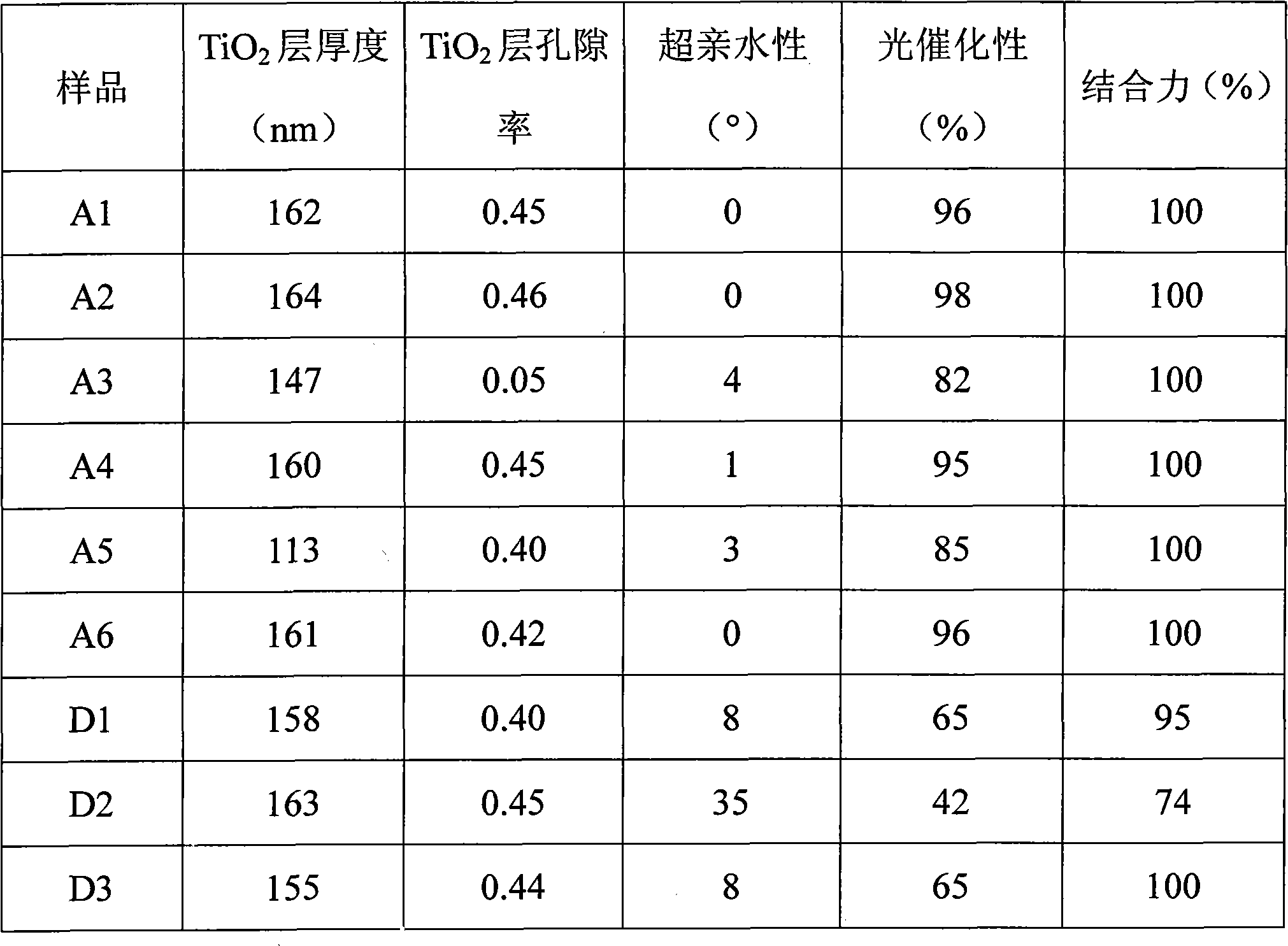

Examples

preparation example Construction

[0021] The present invention also provides a method for preparing self-cleaning glass, comprising the following steps:

[0022] 1) Clean and dry the glass surface;

[0023] 2) forming the nano-silver layer by magnetron sputtering on the glass surface through step 1);

[0024] 3) Prepare urea-containing titanium dioxide sol by sol-gel method, pull and coat the glass in step 2) in the urea-containing titanium dioxide sol, and then form a titanium dioxide layer containing nitrogen-doped titanium dioxide on the glass surface through heat treatment;

[0025] Through the above steps, the self-cleaning glass provided by the present invention is obtained.

[0026] According to the preparation method provided by the present invention, the glass surface needs to be cleaned and dried first. The cleaning and drying methods are various methods commonly used by those skilled in the art, and are not particularly limited in the present invention. For example, it can be: first clean the gla...

Embodiment 1

[0039] This example is used to illustrate the self-cleaning glass of the present invention and its preparation method.

[0040] (1) Glass surface cleaning: Clean the surface stains on the glass (2cm×5cm) with deionized water, then ultrasonically soak and clean in absolute ethanol for 5 minutes, repeat ultrasonic cleaning with deionized water for 3 times, and then dry in an oven at 110°C.

[0041] (2) Magnetron sputtering nano-Ag layer: use magnetron sputtering to sputter a nano-metal Ag film on the glass surface, control the thickness of the sputtered film to be 0.2nm, and obtain a glass slide with a nano-silver layer on the surface. The magnetron sputtering machine is a radio frequency reaction magnetron sputtering machine (produced by Beiyi Innovation Vacuum Technology Co., Ltd., model JP-900A), the sputtering target material is pure Ag palladium, and the sputtering atmosphere is pure argon. During the sputtering reaction, the power supply was 2000W, the vacuum degree was 0....

Embodiment 2

[0047] This example is used to illustrate the self-cleaning glass of the present invention and its preparation method.

[0048] The self-cleaning glass of this embodiment is prepared by the same method as in Example 1, the difference is that in step (2), the thickness of the sputtered film is controlled to be 2nm; the sputtering conditions include: the power supply is 2000W, and the vacuum degree is 0.5 Pa, the sputtering time is 20s, the bias voltage is 150V, and the duty cycle is 80%.

[0049] Through the above method, the self-cleaning glass of this embodiment was obtained, denoted as A2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com