Coal separating equipment with multiple combustors and parent-son pipes

A technology with multiple burners and separation equipment, which is used in combustible gas heating coke ovens, special forms of dry distillation, petroleum industry, etc. properties and stability, ease of storage and utilization, and the effect of reducing water content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

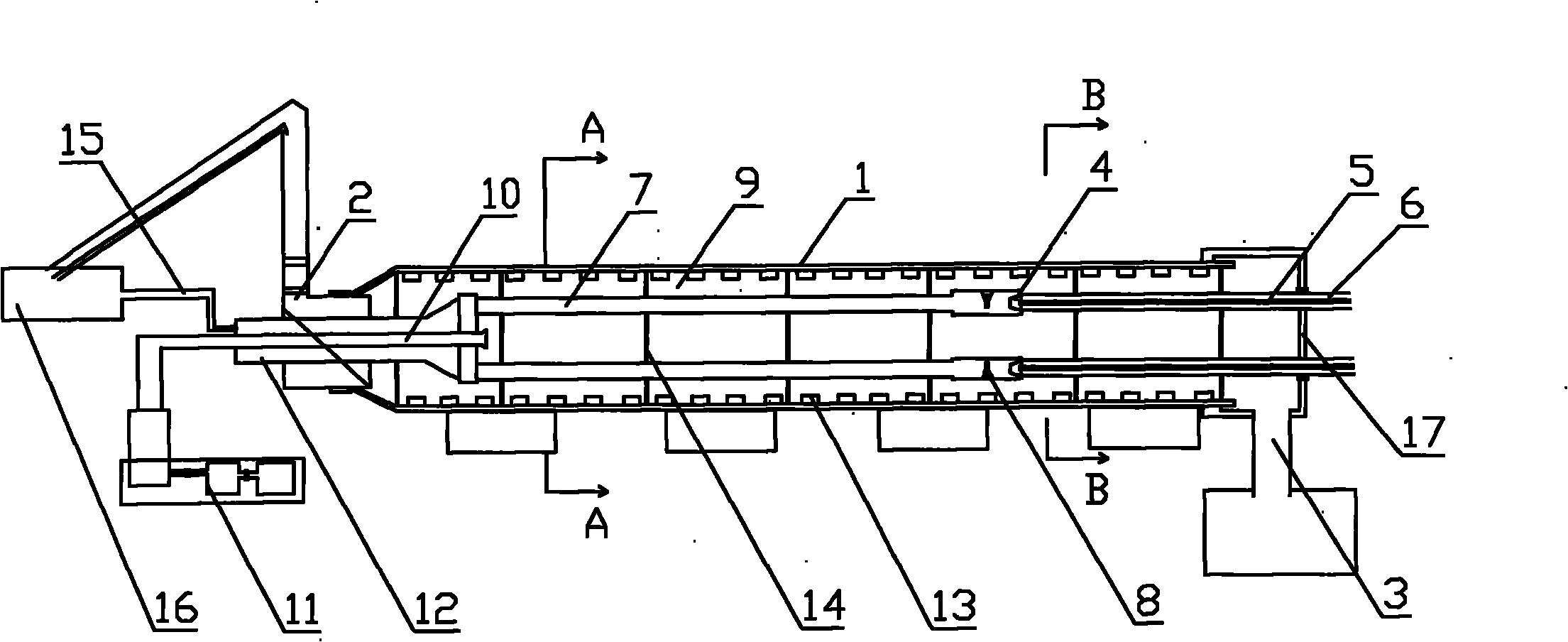

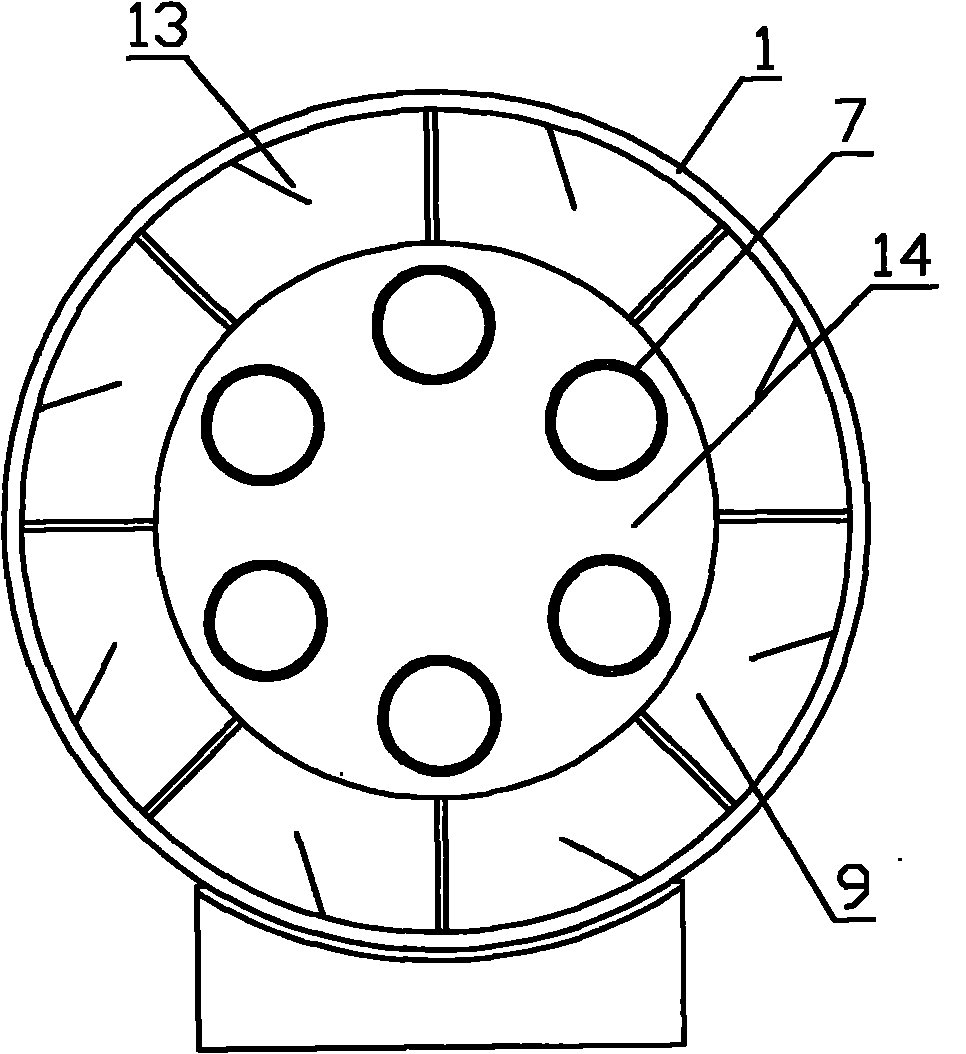

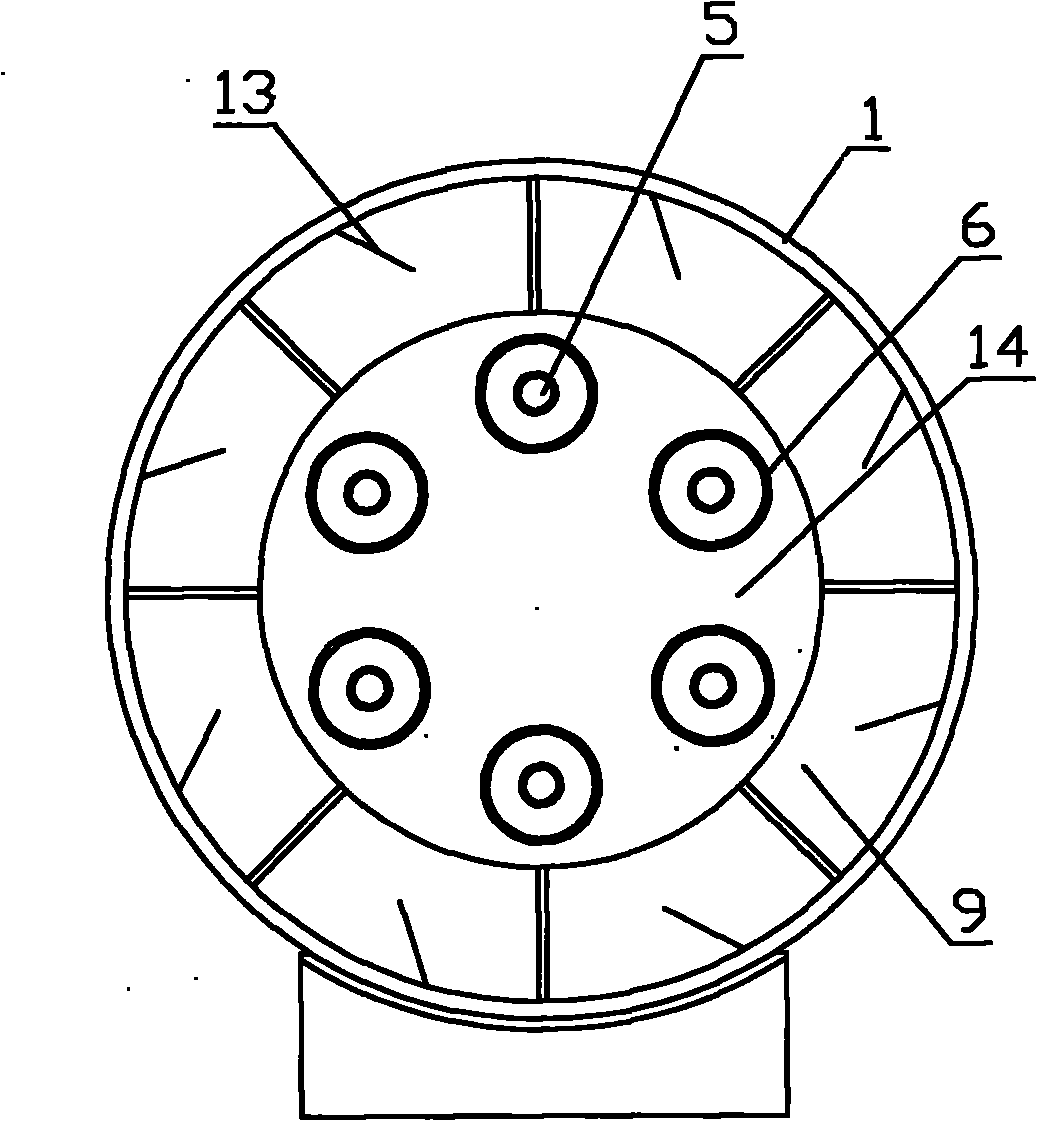

[0018] Such as figure 1 , 2 , 3 shows: a kind of coal material multi-burner sub-pipe separation equipment, including a horizontally arranged sealed rotary kiln body 1, the rotary kiln body 1 includes a feed port 2, a discharge port 3, the rotary kiln body 1 The kiln body 1 is provided with close-packed burners 4 along the direction of the kiln body, and one end of the close-packed burners is provided with close-packed gas intake pipes 5 and close-packed air intake pipes 6, wherein the gas intake pipes are inside the cavity and the air intake pipes are outside. The other end of the close-packed burner is provided with a close-packed flame heat dissipation pipe 7, and an igniter 8 is provided in each burner, and the close-packed burner 4 communicates with the corresponding close-packed gas inlet pipe 5. The row burner 4 communicates with the corresponding close-pack air intake pipe 6, and the close-pack burner communicates with the corresponding close-pack flame heat radiation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com