Steel wire rope for rotary drilling machine and preparation method thereof

A technology of steel wire rope and rotary excavator, applied in the field of steel wire rope, which can solve the problems of reduced service life, low breaking force, and easy wear of hoisting, and achieve the effects of increased service life, strong wear resistance, and increased effective area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

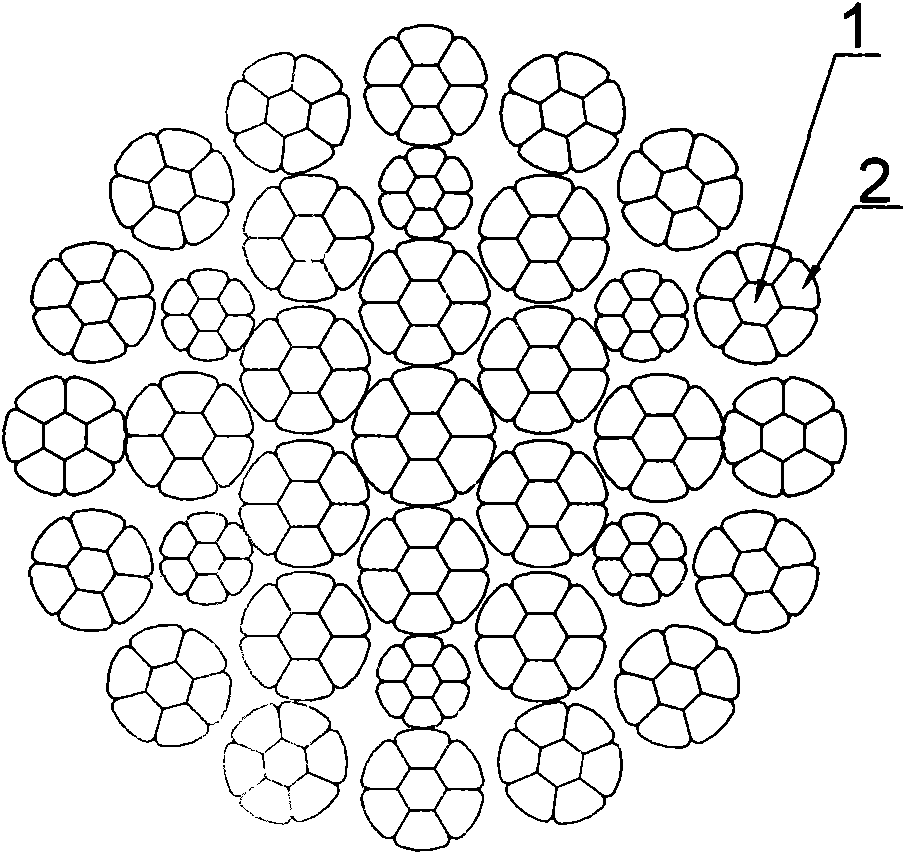

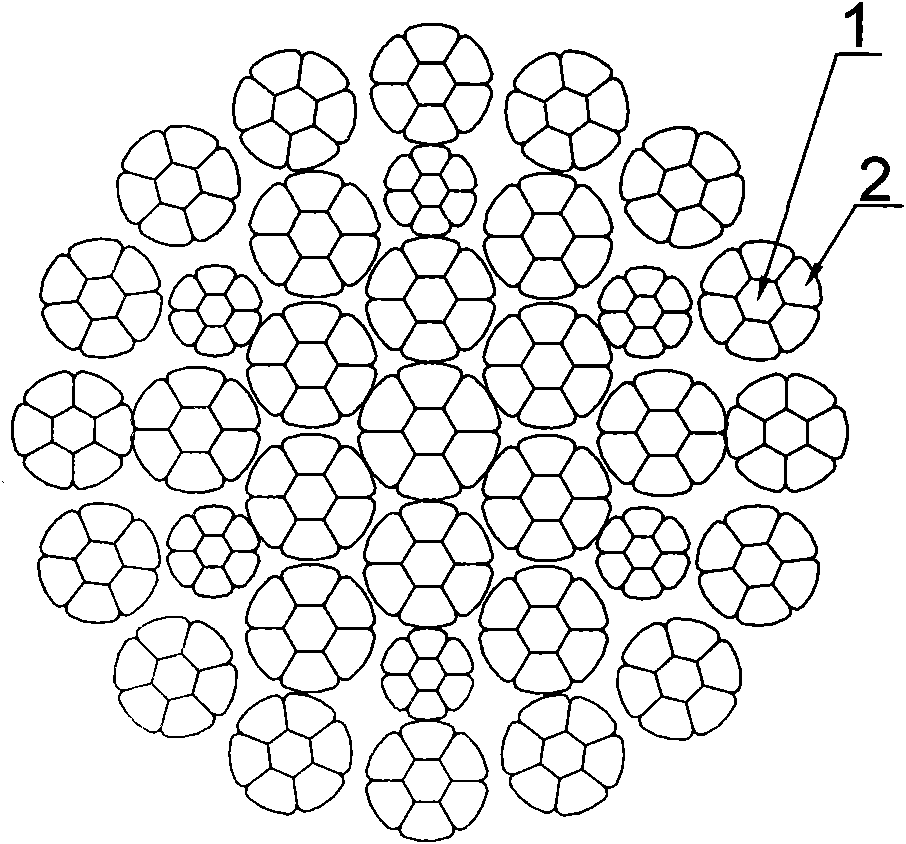

[0026] Such as figure 1 As shown, a steel wire rope for a rotary excavator of the present invention has a specification model of 28NATDL1916AK 1960. It is a fully compacted steel wire rope formed by twisting a central strand wrapped by three layers of strands, wherein the twist direction of the outer strands is the same as The twist direction of the inner two layers of strands is opposite, and each strand is composed of 6 outer layer steel wires 2 wrapped around a central steel wire 1, wherein the outer layer steel wire 2 is approximately trapezoidal, the central steel wire 1 is approximately regular hexagonal, and the inner steel wire and steel wire in surface contact. The steel wire rope of the above structure is formed by twisting twice in a semi-Walington structure of 35 strands. The wire rope is smooth, with a nominal diameter of 28mm and a nominal tensile strength of 1960Mpa.

Embodiment 2

[0028] The preparation method of the steel wire rope for rotary excavator of the present invention is to use the production method of die drawing to cold-draw the steel wire rope strands with a mold when twisting the strands, change the shape of the steel wires in the strands but basically not change the cross-sectional area of the steel wires, and make the strands inside the strands There is a surface contact between the steel wire and the steel wire, and then the rope is closed.

[0029] At the same time, when producing the rope, oil is injected into the strands, and the steel wire rope goes through the oil pan. The inside of the steel wire rope is also filled with grease, and the oil content of the whole rope is increased, which further improves the fatigue resistance of the steel wire rope and meets the requirements of the steel wire rope for rotary excavators. requirements.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Nominal diameter | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com