Alkali-free compound flooding composition

An alkali-free composite flooding and composition technology, which is applied in the direction of drilling composition, chemical instruments and methods, can solve the problems of increasing the cost of oil displacement agents, shortening the pump inspection cycle, and insufficient quantity supply, etc., and achieves good results. Good interfacial tension and long-term stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

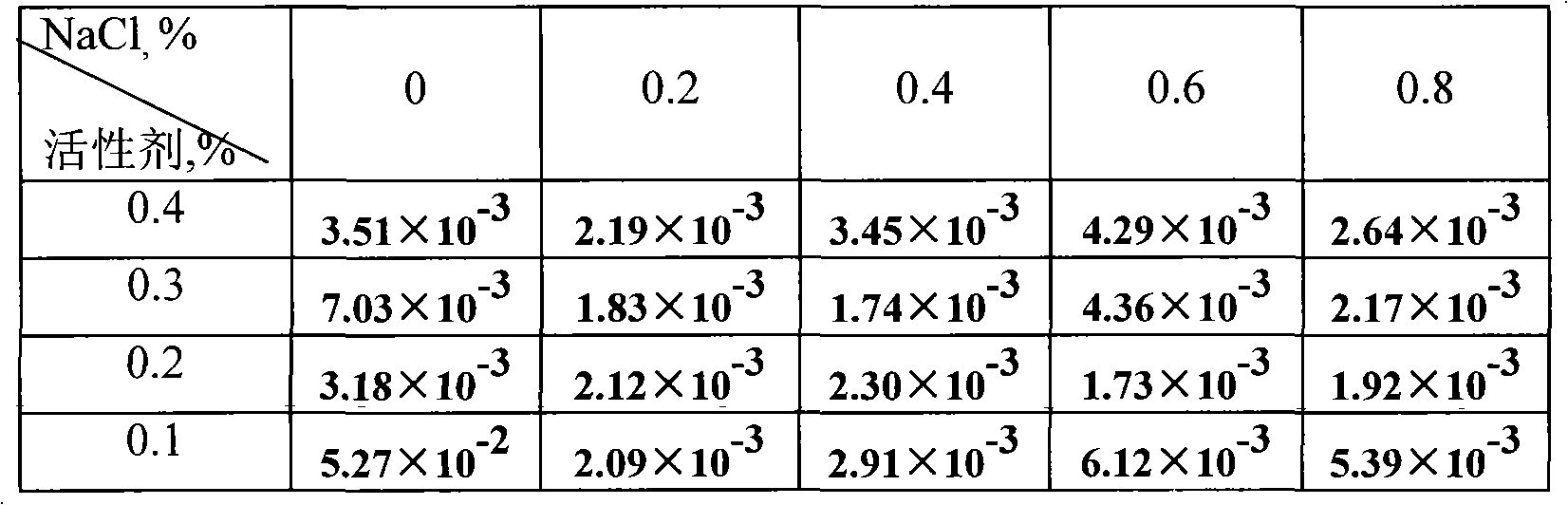

[0031] Determination of interfacial tension of crude oil sample T1

[0032] The weight ratio of the composite surfactant is: petroleum sulfonate: alkanolamide=30:70.

[0033] Table 1 Interfacial tension of composite surfactants on crude oil (T1) / injected sewage (KYPAM 1200mg / L)

[0034]

[0035] Note: The salinity of the injected sewage is 4000mg / l.

[0036] Table 2 Interfacial tension of composite surfactants on crude oil (D1) / injected sewage (HPAM 1300mg / L)

[0037]

Embodiment 2

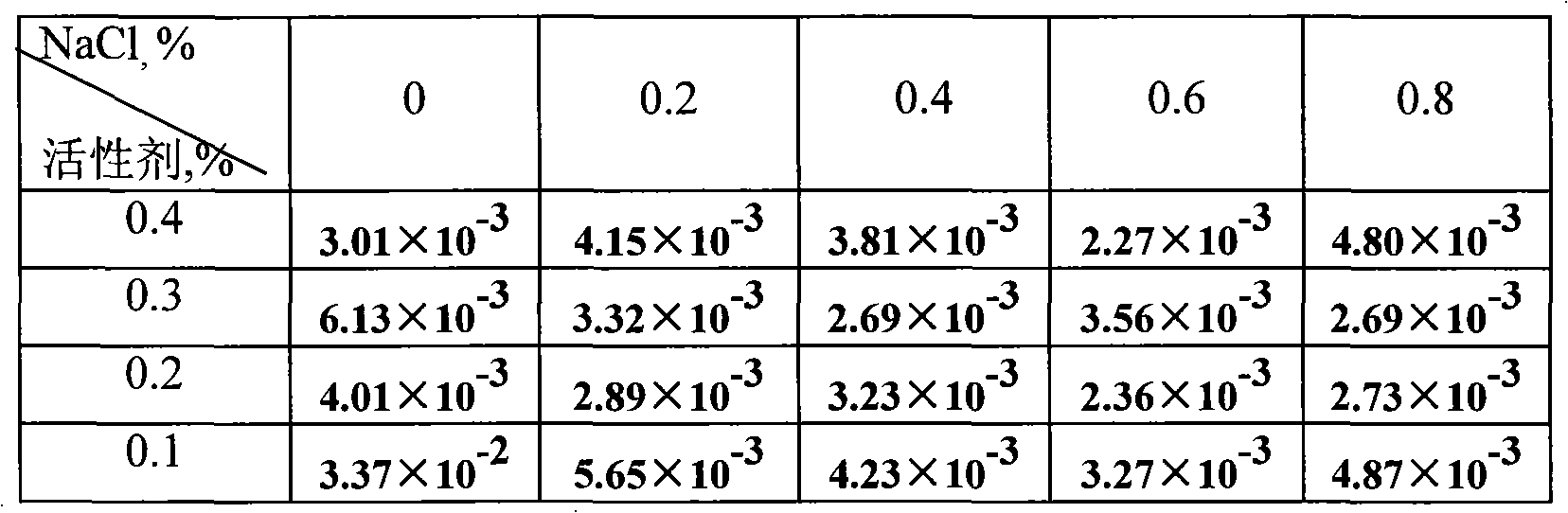

[0039] Determination of interfacial tension of crude oil sample T2

[0040] The weight ratio of the composite surfactant is: petroleum sulfonate: alkanolamide=20:80.

[0041] Table 3 Interfacial tension of composite surfactants on crude oil (T2) / injected mixed sewage (KYPAM 1200mg / L)

[0042]

[0043] Note: The salinity of the injected mixed sewage is 6000mg / l.

[0044] Table 4 Interfacial tension of composite surfactant to crude oil (T2) / injected mixed sewage (KYPAM 1200mg / L)

[0045]

Embodiment 3

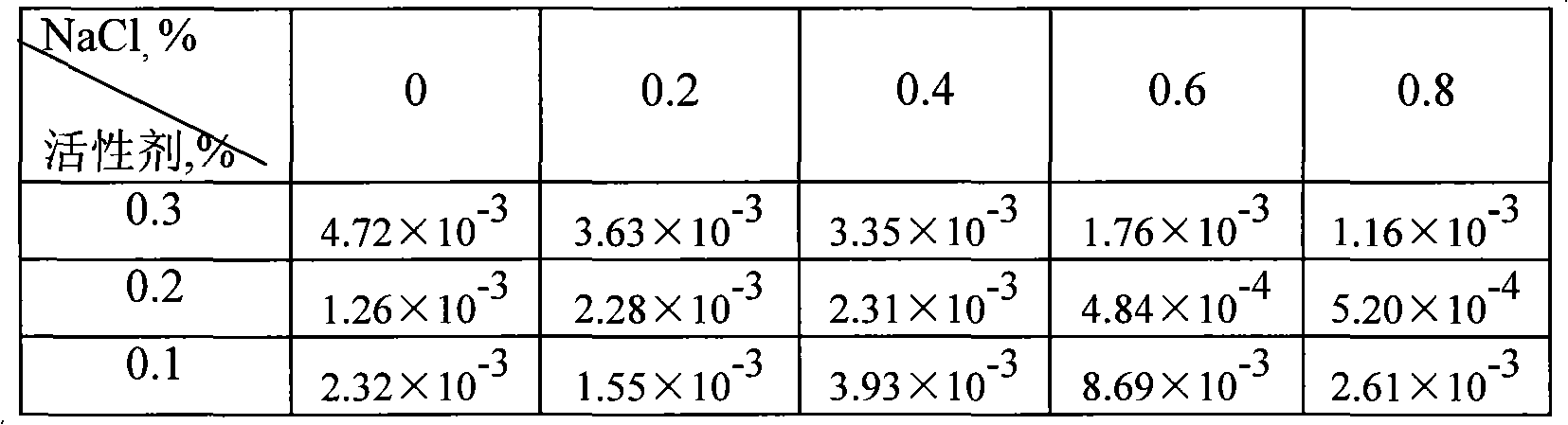

[0047] Measurement of interfacial tension of crude oil samples in different blocks

[0048] The weight ratio of the composite surfactant is: petroleum sulfonate: alkanolamide=25:75. No salt.

[0049] Table 5 Adaptability of composite surfactants to crude oil in the test area / Interfacial tension of injected sewage (KYPAM 1200mg / L)

[0050]

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com