Pressure-bearing dual-cycle all-plastic water tank liner of heat exchanger

A heat exchanger, double-cycle technology, applied in heat exchanger types, indirect heat exchangers, fluid heaters, etc., can solve the problems of large heat loss, large circulation resistance of enamel liner, and high cost, and achieve low heat loss. , The effect of eliminating the automatic water level control system and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

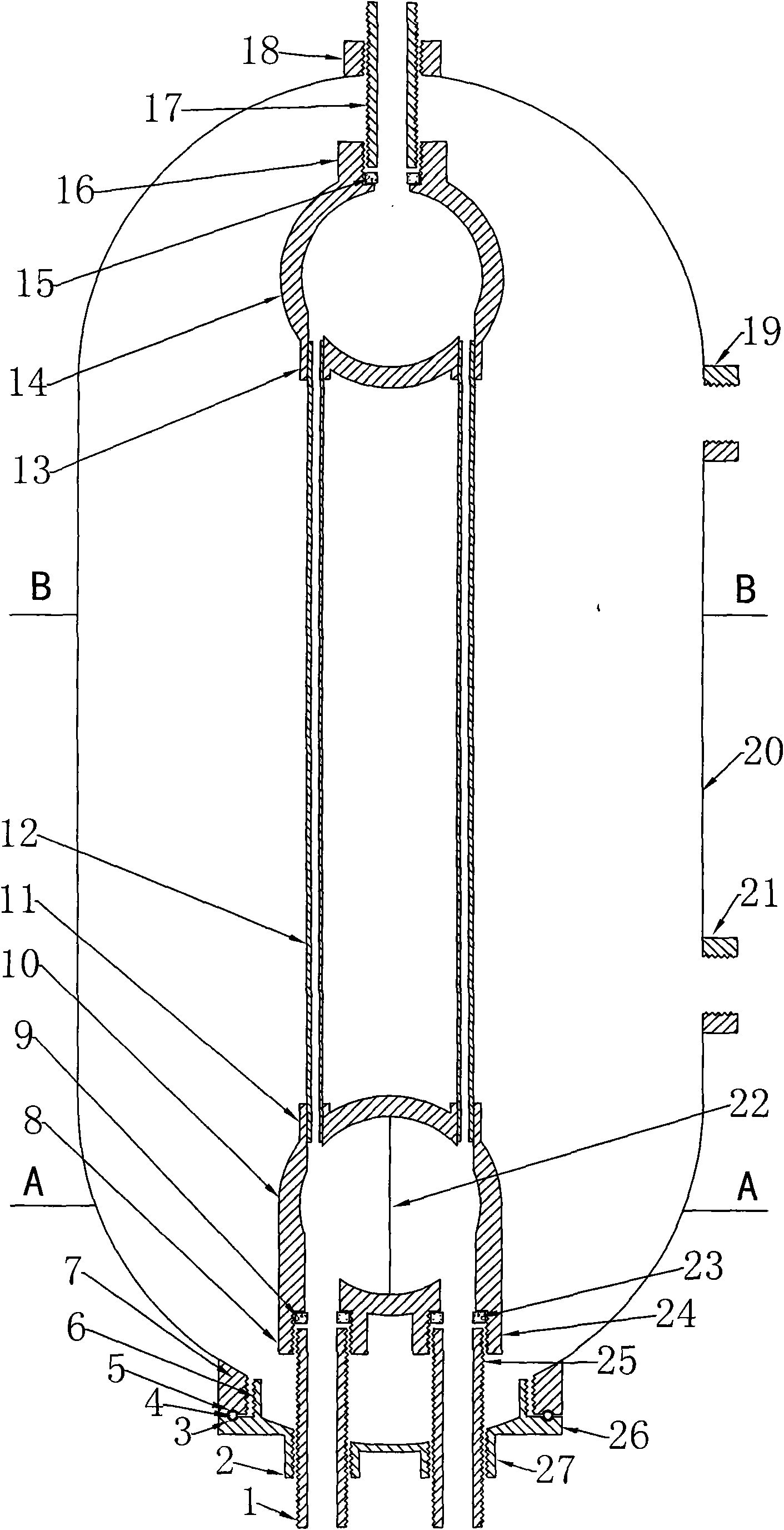

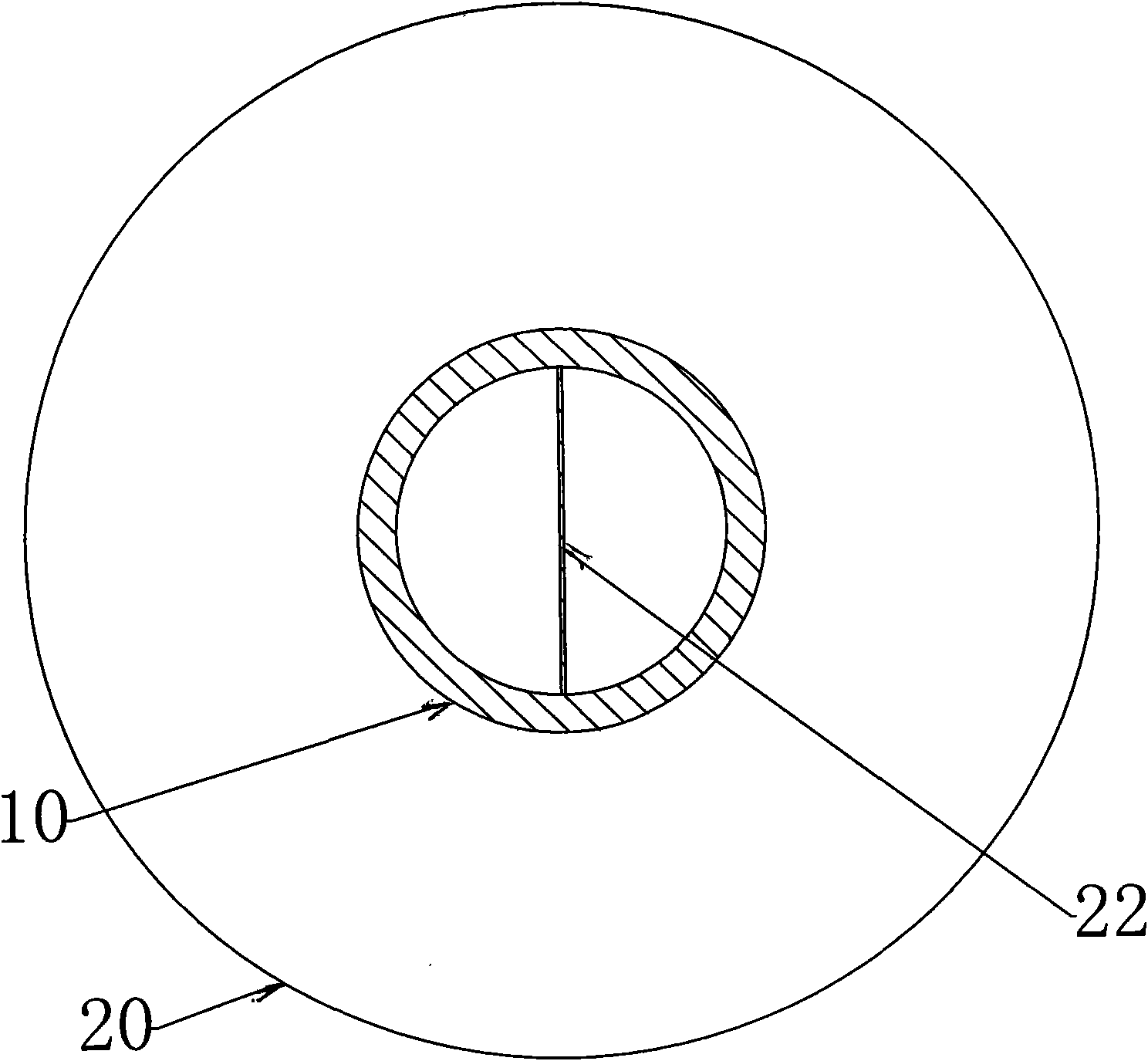

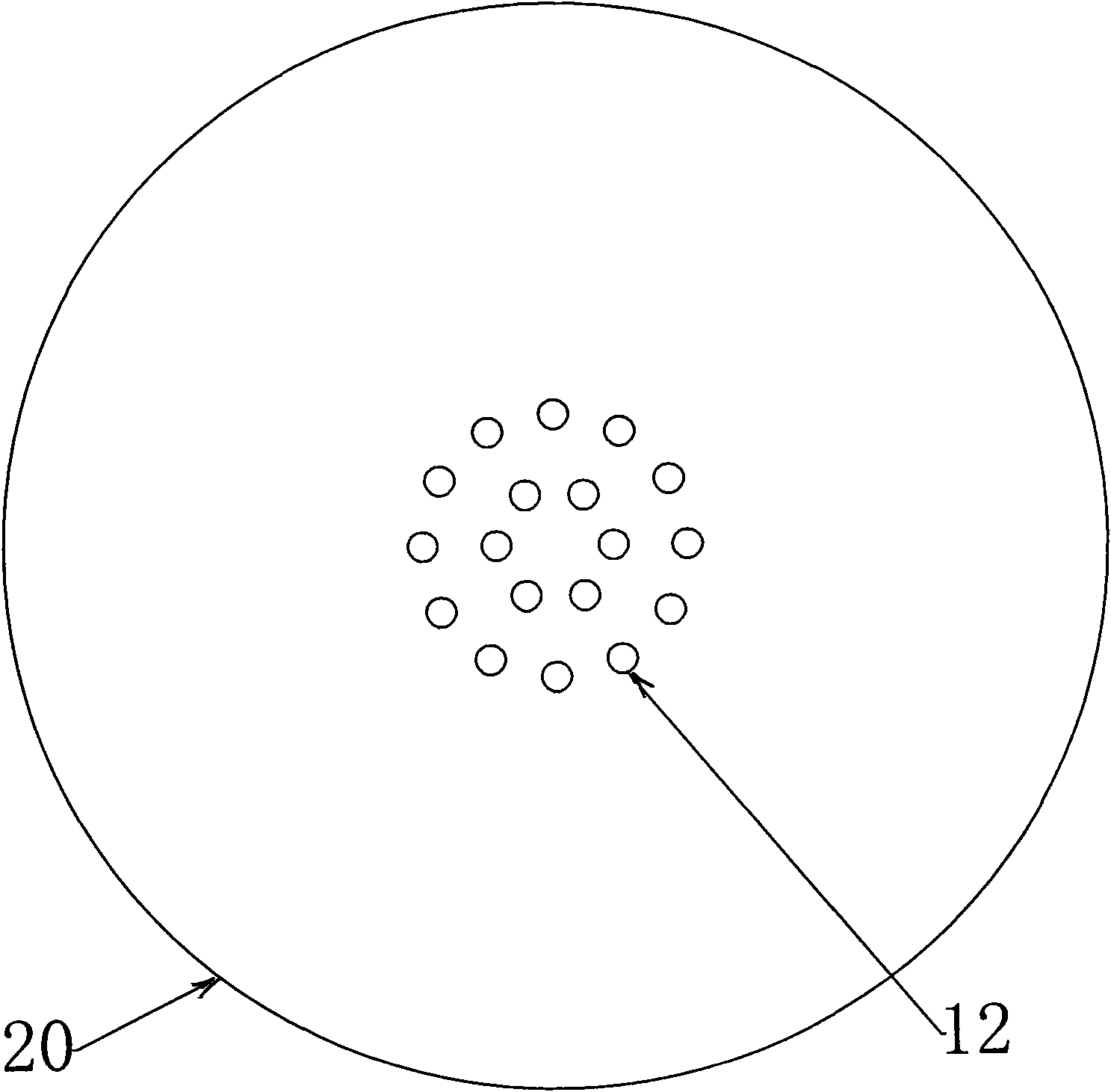

[0021] figure 1 , figure 2 , image 3 The structure form of the water tank liner of a pressure-bearing double-circulation all-plastic heat exchanger is described together. The shell 20 is made of metal materials, or metal enamel materials, or metal composite polymer materials, or polymer materials, or modified polymer materials, or reinforced polymer materials. The shell 20 is welded with nuts 7, nuts 18, The hot water outlet pipe 19, the cold water inlet pipe 21; the nut 7 has an annular groove 5, the sealing cover 26 has an annular groove 3, and a waterproof rubber ring 4 is placed between the annular groove 3 and the annular groove 5; when the screw 6 is turned When tightening on the nut 7, the sealing cover 26 compresses the waterproof rubber ring 4 tightly. When the screw outside the circulation pipe 1 is tightened on the nut 8, the waterproof gasket 9 is compressed; when the screw outside the circulation pipe 25 is tightened on the nut 24, the waterproof gasket 23 is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com